Residence discharge flue processing technique

A processing technology and flue gas technology, applied in the field of residential flue gas duct processing technology, can solve the problems of uneven wall thickness of the flue gas duct, blocked airflow, rough inner wall, etc., so as to improve labor efficiency, improve product quality, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

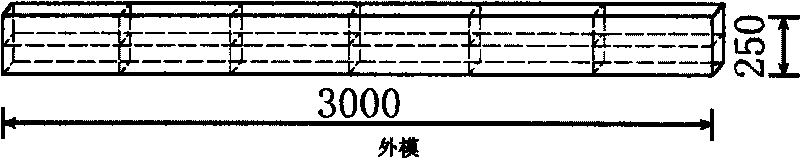

[0016] In the bottom mold ( figure 1 ) on the position of the outer mold ( figure 2 )→Use the fixed template fixture ( Figure 6 ) fixed outer mold ( figure 2 ) Both ends should be firm → the outer mold ( figure 2 ) support the glass wire mesh and prepare the mortar at the bottom of the flue gas channel → support the inner mold ( image 3 ) with a screw adjuster ( Figure 5 ) to the design thickness → use the inner mold ( image 3 ) to incline at an angle of 70° and add an appropriate amount of mortar → adjust the upper screw adjuster ( Figure 5 ) extrude the mortar to the design thickness → place the upper top mold ( Figure 4 ) → Make flat top mortar → After 48 hours of curing, the formwork can be removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com