Scraper blade structure of large tilt angle conveyor crate

A technology of conveyors and large inclination angles, applied in the field of conveyor chains, can solve the problems of large land occupation and increased manufacturing costs of conveyors, and achieve the effects of easy manufacturing, simple structure, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

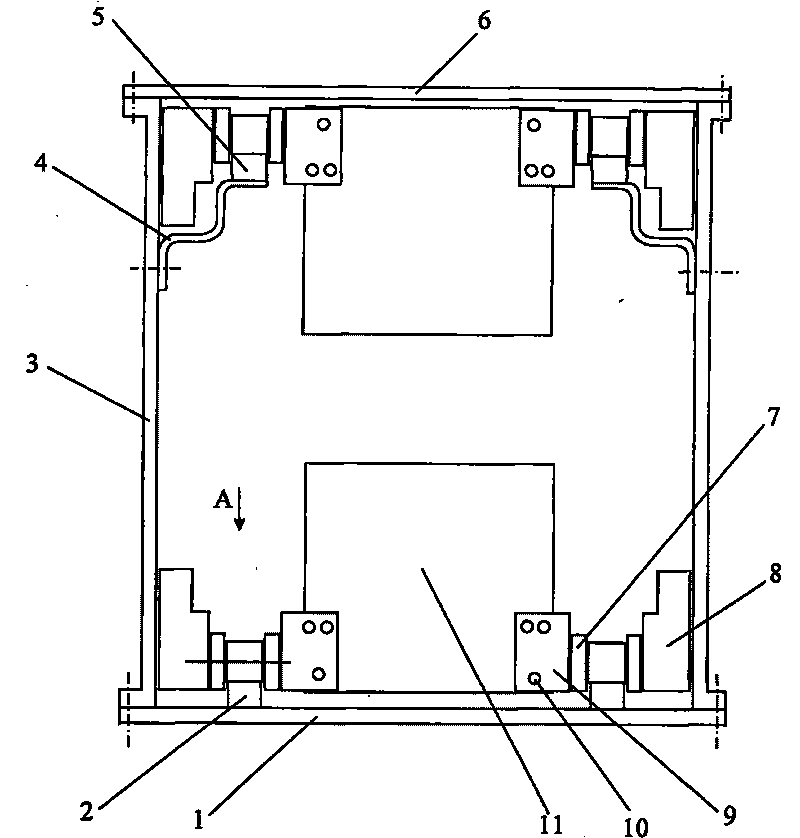

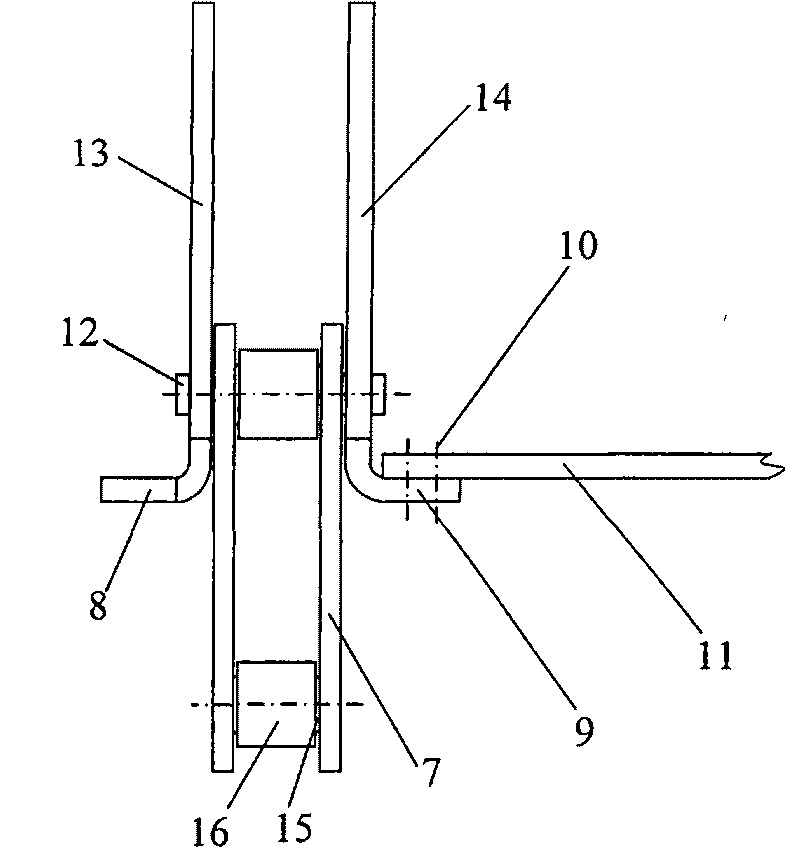

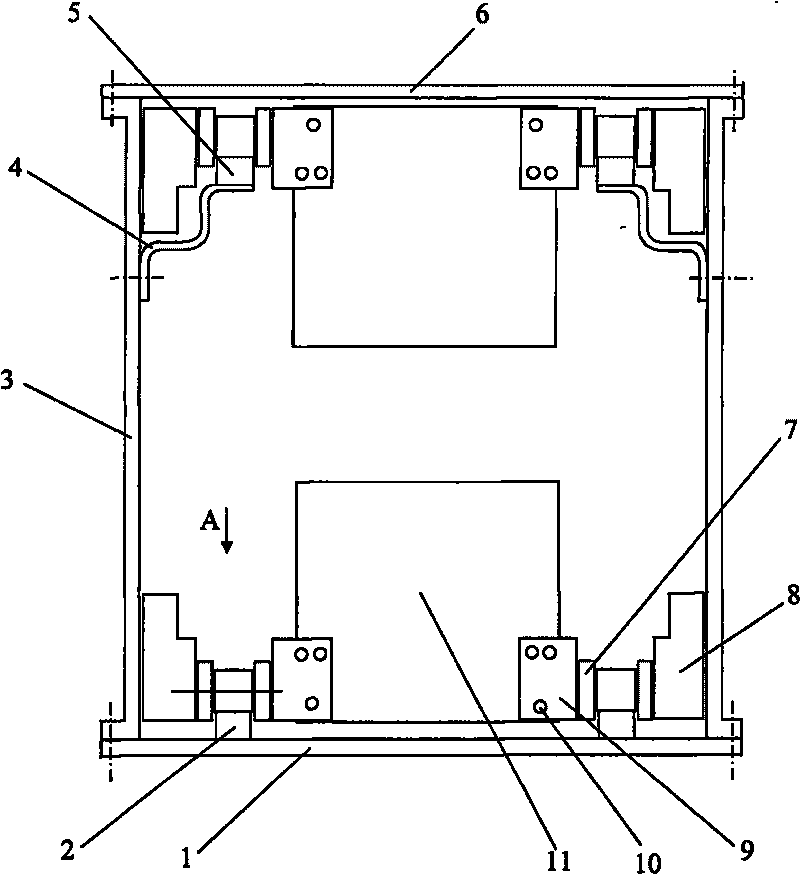

[0014] Such as figure 1 , figure 2 As shown, the box is composed of a bottom plate 1, two side plates 3 and a cover plate 6. Two parallel process rails 2 are installed on the bottom plate of the box body, and two parallel process rails 2 are installed on the two side plates through two brackets 4. The return track 5 is equipped with two moving chains with scrapers on the two progress tracks and the two return tracks. The chain consists of an inner chain plate 7, a sleeve 15, a roller 16, a pin shaft 12 and an outer chain plate 13, 14 constitute. Described chain scraper is that the front end of outer chain plate 13 of two chain outsides is shaped on outwardly curved flanging 8, and this flanging is to bend outwards 90 °, and this flanging w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap