Multiplex heat treatment method for Cu-12 percent Fe alloy

A composite heat treatment, cu-12 technology, applied in the field of composite heat treatment of Cu-12% Fe alloy, can solve the problems of unfavorable solid solution solute, grain coarsening and uneven size, unsatisfactory degree of sufficiency and uniformity, etc. Achieve uniform distribution of precipitated phase particles, improve hardness and electrical conductivity, and control flexibly and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

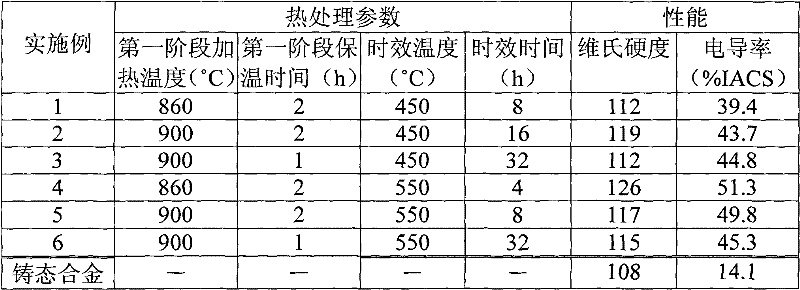

Examples

Embodiment 1

[0024] Put 12% industrial pure iron with a given mass percentage ratio and the rest are electrolytic copper raw materials in a vacuum induction furnace, heat to 1400°C under an atmospheric pressure of less than 0.1Pa to melt, stir evenly by electromagnetic stirring and stand for 2 to 3 minutes to remove After filling the furnace with Ar to 30kPa, cast it into a rod-shaped ingot with a diameter of Φ20.0mm;

[0025] Heat the ingot in a vacuum heat treatment furnace to the first stage at an average heating rate of 10°C / min to 860°C for 2 hours, then heat at an average heating rate of 4°C / min to the second stage at 950°C for 0.5 hours, and then Heating at an average heating rate of 4°C / min to the solid solution temperature of 1000°C and holding for 0.5h, then water cooling.

[0026] After water cooling, the ingot is heated to 450°C at an average heating rate of 10°C / min in a box-type heat treatment furnace, and then air-cooled. After this heat treatment process, the electrical co...

Embodiment 2

[0028] Put 12% industrial pure iron with a given mass percentage ratio and the rest are electrolytic copper raw materials in a vacuum induction furnace, heat to 1400°C under an atmospheric pressure of less than 0.1Pa to melt, stir evenly by electromagnetic stirring and stand for 2 to 3 minutes to remove After filling the furnace with Ar to 30kPa, cast it into a rod-shaped ingot with a diameter of Φ20.0mm;

[0029] Heat the ingot in a vacuum heat treatment furnace at an average heating rate of 10°C / min to the first stage of 900°C for 2 hours, then heat at an average rate of 4°C / min to the second stage of 950°C for 0.5h, and then Heating at an average heating rate of 4°C / min to the solid solution temperature of 1000°C and holding for 0.5h, then water cooling.

[0030] After water-cooling, the ingot was heated to 450°C at an average heating rate of 10°C / min in a box-type heat treatment furnace and kept for 16 hours, then air-cooled. After this heat treatment process, the electri...

Embodiment 3

[0032] Put 12% industrial pure iron with a given mass percentage ratio and the rest are electrolytic copper raw materials in a vacuum induction furnace, heat to 1400°C under an atmospheric pressure of less than 0.1Pa to melt, stir evenly by electromagnetic stirring and stand for 2 to 3 minutes to remove After filling the furnace with Ar to 30kPa, cast it into a rod-shaped ingot with a diameter of Φ20.0mm;

[0033] Heat the ingot in a vacuum heat treatment furnace to the first stage of 900°C at an average heating rate of 10°C / min and keep it for 1h, then heat it at an average heating rate of 4°C / min to the second stage of 950°C for 0.5h, and then Heating at an average heating rate of 4°C / min to the solid solution temperature of 1000°C and holding for 0.5h, then water cooling.

[0034] After water-cooling, the ingot was heated to 450°C at an average heating rate of 10°C / min in a box-type heat treatment furnace and kept for 32 hours, then air-cooled. After this heat treatment pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com