Solid medium contained plunger pump stuffing sealing device

A technology of packing seal and plunger pump, applied in the field of packing seal, can solve the problems of complex structure, depend on the reliability of the oil injection pump, and high production cost, and achieve the effects of unique and simple structure, low production cost, and avoidance of wear and tear.

Inactive Publication Date: 2010-06-09

CHINA COAL RES INST +1

View PDF1 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its structure is relatively complicated, the production cost is hig

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

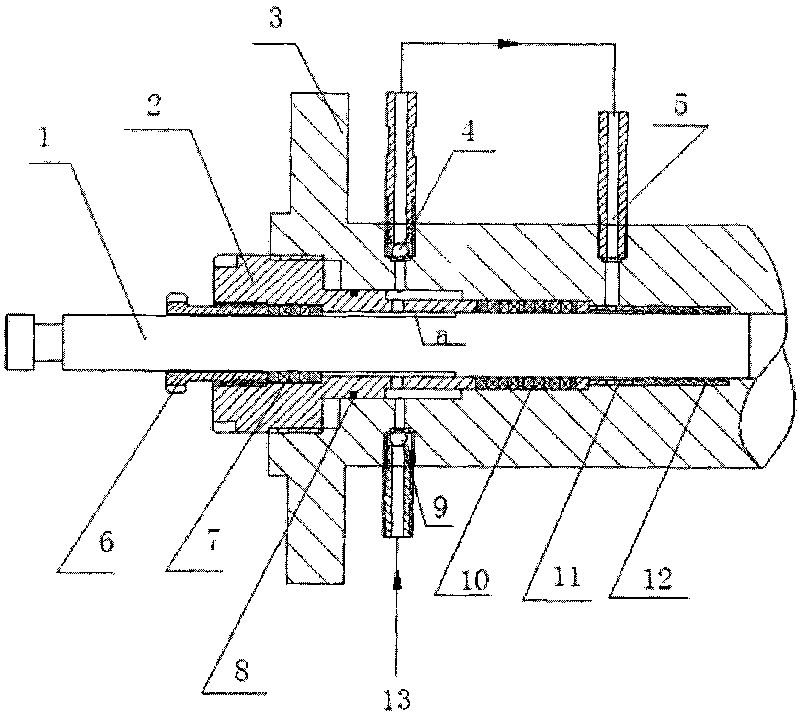

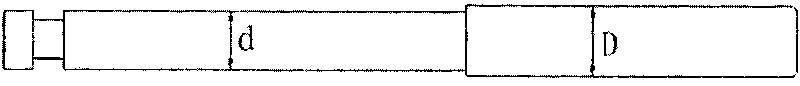

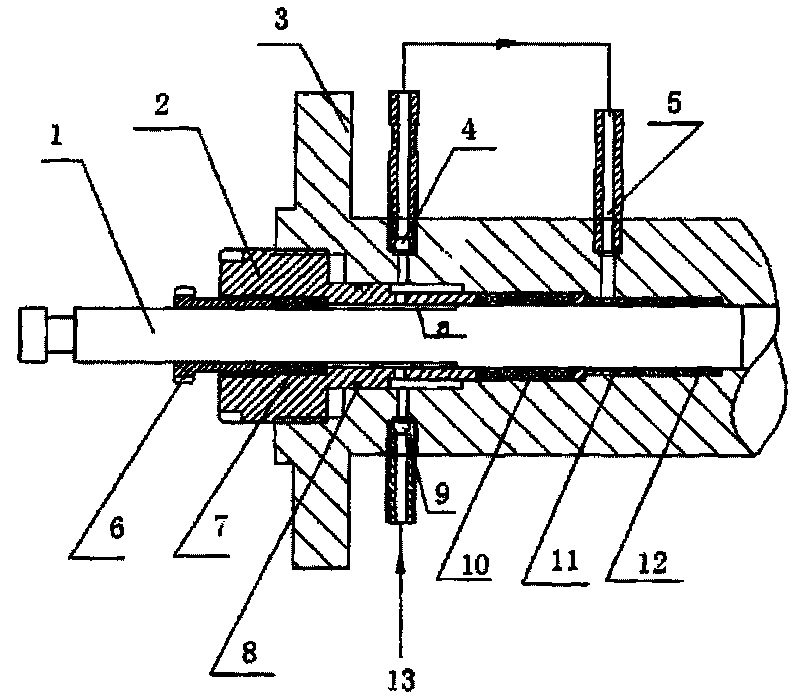

The invention relates to a solid medium contained plunger pump stuffing sealing device which comprises a plunger, a main stuffing press cover, a stuffing body, an outlet one-way valve, a flushing fluid pipe, an auxiliary stuffing press cover, an auxiliary stuffing box, an O-shaped ring, an inlet one-way valve, a main stuffing box, a flushing fluid guide ring and an isolated body. The stuffing body is coated at the periphery of the plunger, the front end of the stuffing body is connected with a pump head, the rear end is connected with a power part, the isolated body is arranged between the inside of the stuffing body and the plunger, the isolated body is of a tooth slot-shaped structure, and the flushing fluid guide ring is arranged behind the isolated body. The stuffing body and the plunger are sealed through the main stuffing box, the main stuffing box is compressed through the main stuffing press cover, the main stuffing press cover is in threaded connection with the stuffing body, and the main stuffing press cover is sealed through an O-shaped seal ring. The main stuffing box is a plurality of groups of stuffing which is formed by alternately assembling a packing and a lined ring, and performs an absolute sealing action on a pump conveying medium. The main stuffing press cover and the plunger are sealed through the auxiliary stuffing box, and the auxiliary stuffing box is compressed through the auxiliary stuffing press cover.

Description

technical field [0001] The invention relates to the field of packing sealing used in petroleum, chemical industry, coal chemical industry, food, etc., in particular to a packing sealing device of a plunger pump containing solid medium. Background technique [0002] In the coal liquefaction process, the delivery medium of the coal-water slurry and oil-coal slurry feed pump contains a large amount of coal powder particles, and the mud delivered by the drilling plunger pump used in the oil field contains a large amount of broken rock particles, and the delivery medium of the oilfield water injection pump Also contains a lot of sediment. During the operation of the plunger pump under the above working conditions, the solid particles in the conveying medium are easy to wear the plunger and packing, making the pump seal easy to leak, resulting in the pump not working normally, and frequent replacement of packing, affecting normal production. [0003] Chinese Patent Publication No...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04B53/02

Inventor 李文博兰建华朱晓苏章序文史士东何建铧王雨吴向阳何平陈珏

Owner CHINA COAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com