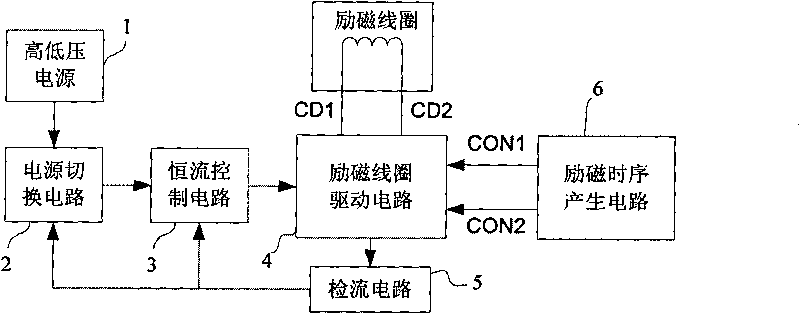

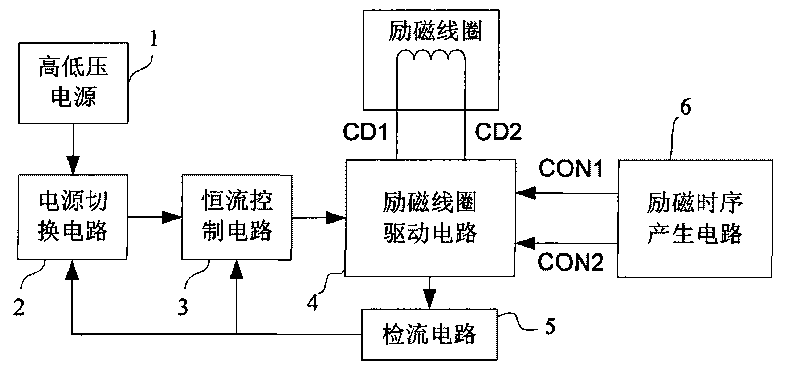

Electromagnetic flow meter excitation control system based on high and low voltage power switching

An electromagnetic flowmeter and power switching technology, which is applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effects, measurement flow/mass flow, etc., can solve the limitation of input and output pressure difference and large heat dissipation , large circuit board area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

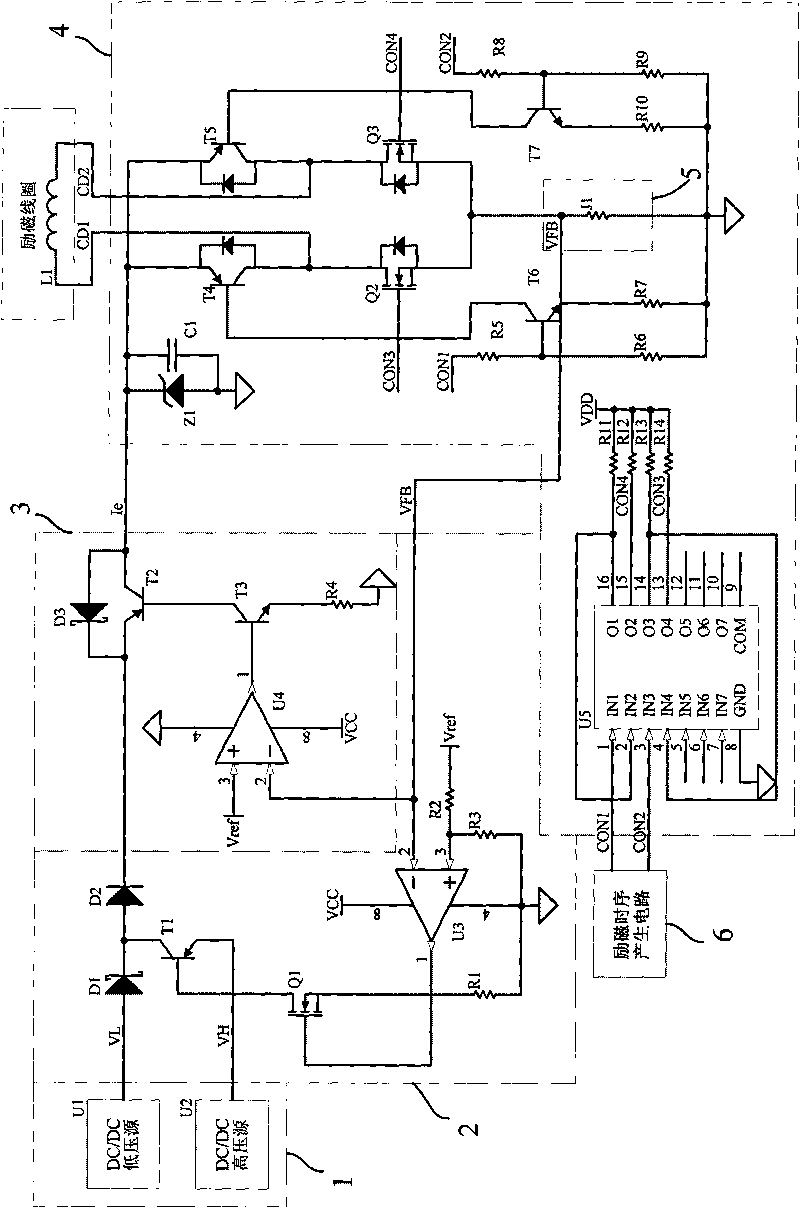

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] The present invention is based on the applied invention patent "A Single / Dual Frequency Electromagnetic Flowmeter Excitation Control System Based on Linear Power Supply", and improves the excitation power supply part and the constant current control part. Its purpose is to improve the efficiency of power utilization and to further broaden the range of excitation frequency on the premise of ensuring the stability of the zero point of the electromagnetic flowmeter, so as to provide conditions for the increase of excitation frequency in slurry measurement. The design idea of the present invention is to convert the excitation working voltage source into a current source through current negative feedback constant current control, so as to provide a constant excitation steady-state current for the excitation coil. Provided by the low-end current detection circuit of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com