Automatic shaping and pouring device for laver pie

An automatic pouring and seaweed technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of low production efficiency, low commodity value, uneven weight, etc., and achieve the effect of safe and hygienic production process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

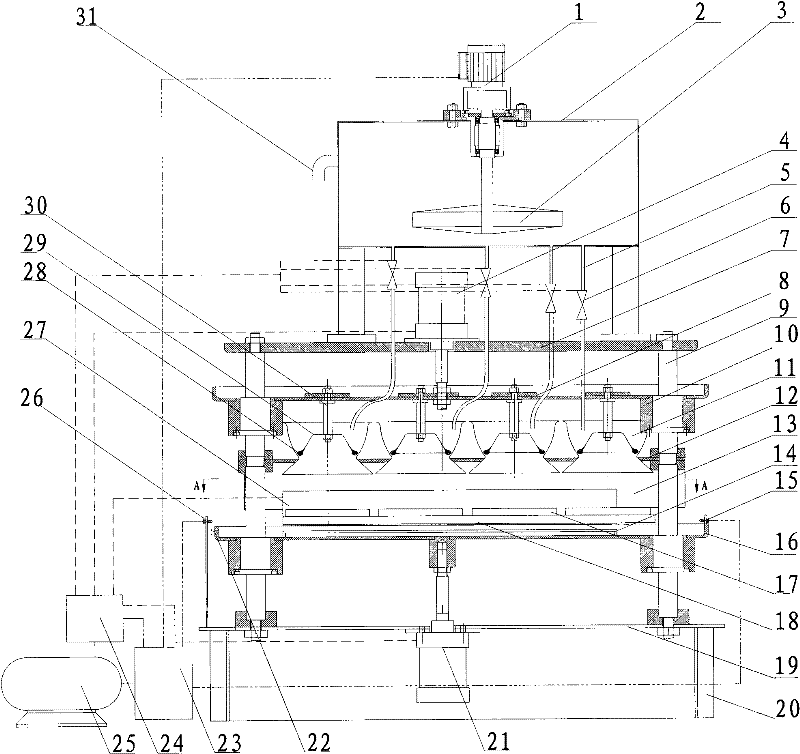

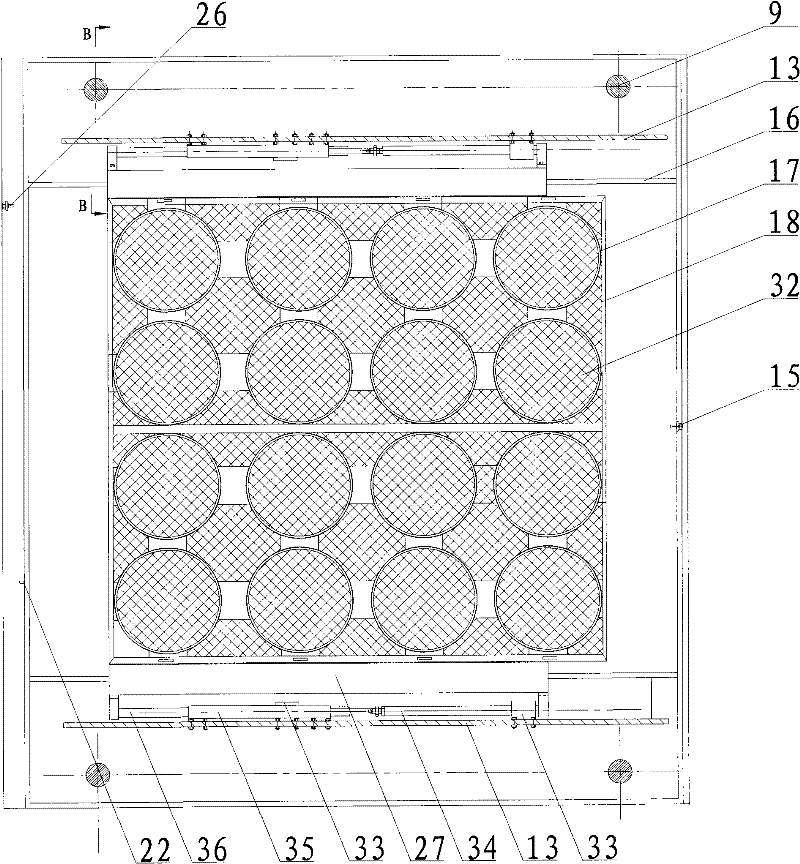

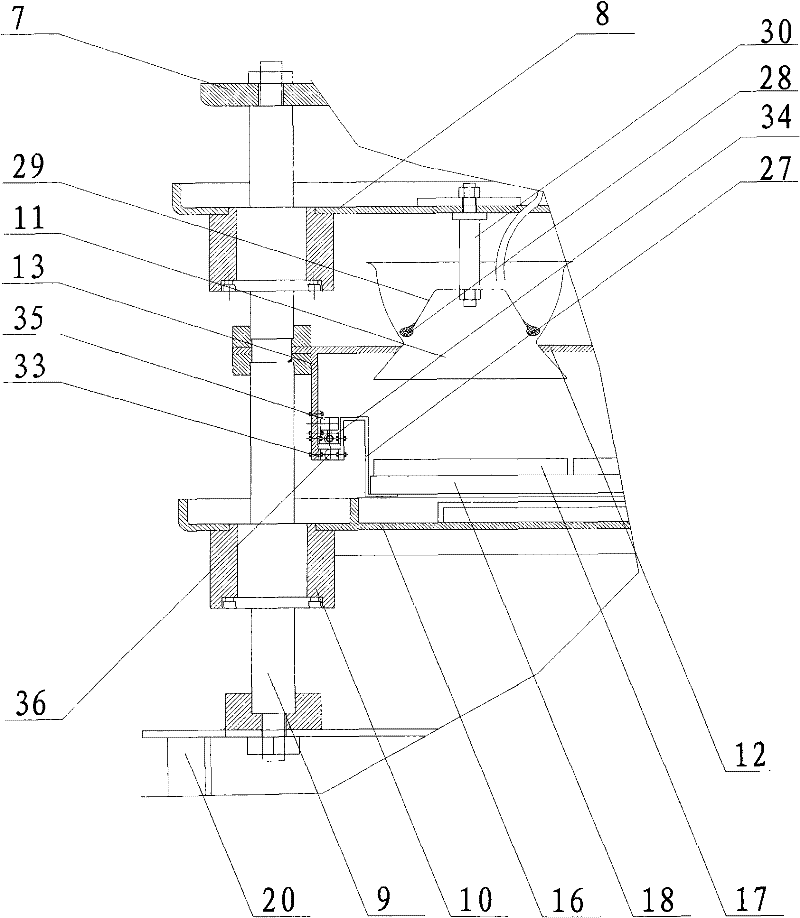

[0021] As shown in the accompanying drawings, the laver cake forming automatic pouring device includes a frame 20, a pouring forming assembly, a feed liquid supply assembly, a conveying assembly, a separator 24, a controller 23, and a former. Casting forming assembly, material liquid supply assembly, conveying assembly; pouring forming assembly has a base 19, a cover plate 7, a large column 9, a linear bearing 10, an upper tray 8, a cone cover 29, a screw 30, a sealing ring 28, The lower tray 12, the distributor 11, the water tray 16, the feeding cylinder 4, the water tray cylinder 21, the base 19 are rigidly fixed on the frame 20, and the lower ends of the four large columns 9 are center-symmetrically distributed and fixed on the four corners of the base 19 through nuts , the upper ends of the four large columns 9 are rigidly connected with the cover plate 7 through nuts, and the large column 9 is provided with a linear bearing 10 guided by the large column, between the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com