Ground brush of rolling brush type dust collector

A vacuum cleaner and roller brush technology, applied in the field of roller brush vacuum cleaner floor brush, can solve the problems of carpet damage, obstruction of floor brush movement, difficult carpet long wool cleaning, etc., to reduce damage, reduce air intake resistance, and reduce self- effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred implementations of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the following implementations are for illustration only, and are not intended to limit the protection scope of the present invention.

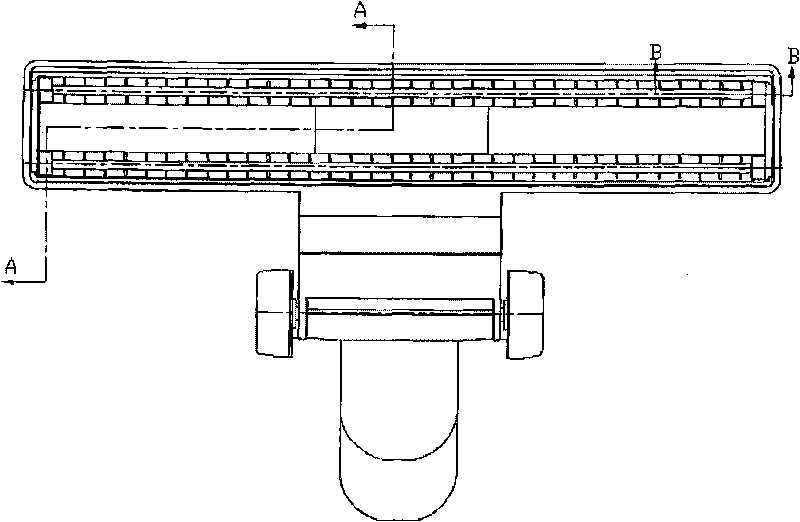

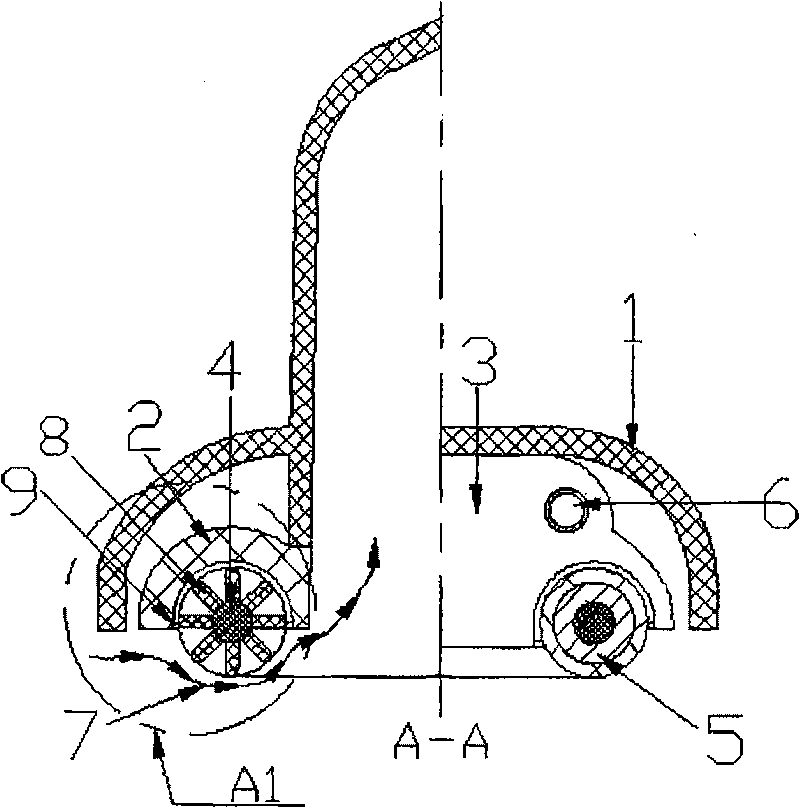

[0032] like figure 1 and figure 2 As shown, the ground brush of the roller brush vacuum cleaner includes an air pipe connection part and a ground brush main body. The air pipe connection part is connected to the air pipe not shown in the figure, and a cavity communicating with the air pipe is formed inside, and casters are provided at the bottom. When in use, the user pushes the air duct, and the floor brush moves on the ground by means of casters. Here, the structure of the air duct connecting portion is already known, so its detailed description is omitted here.

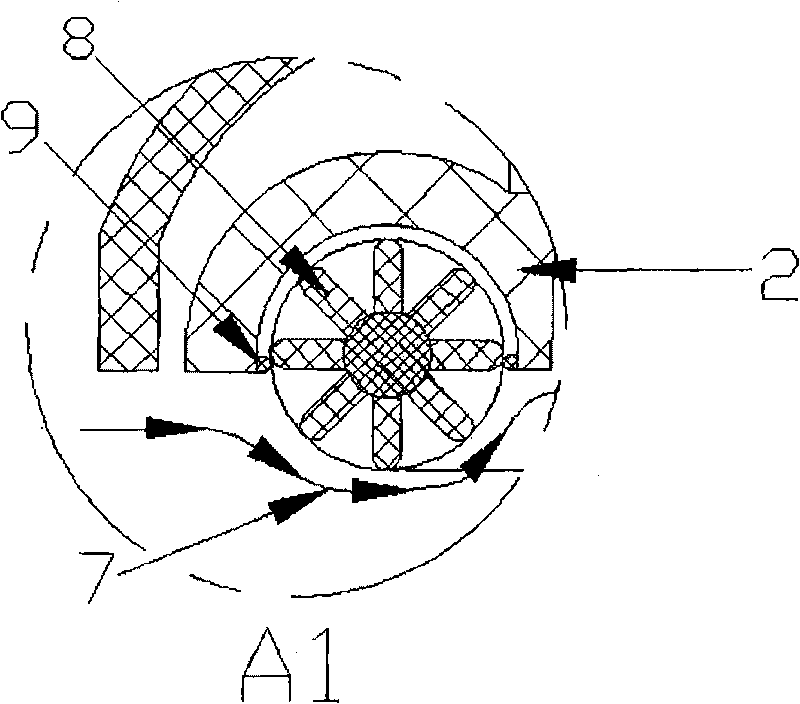

[0033] like figure 2 As shown most clearly in , the main part of the floor brush includes an upper cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com