Supplying device for zipper tapes in zipper teeth chain continuous making machine

A supply device and zipper tape technology, which can be used in transportation and packaging, clothing, thin material processing, etc., and can solve problems such as large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

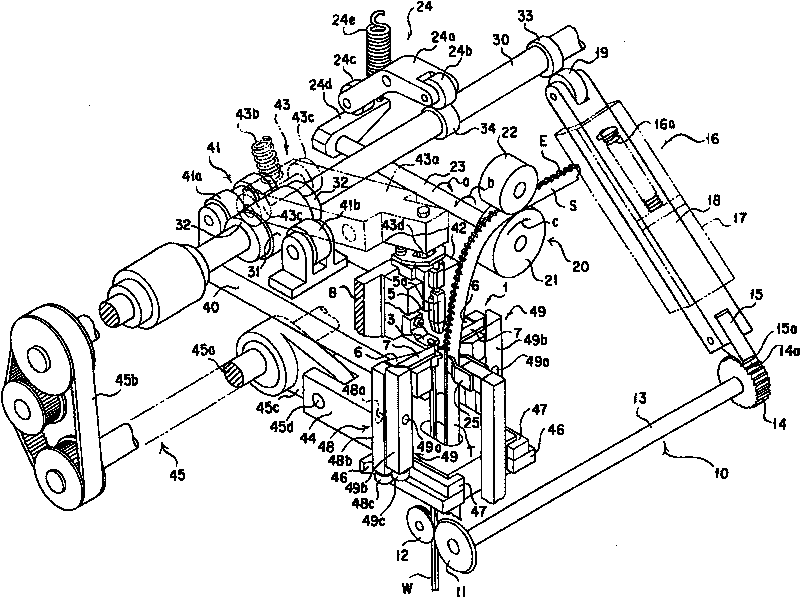

[0038] The structure of the main part of the fastener stringer continuous manufacturing machine of this invention is demonstrated.

[0039] Such as figure 1 As shown, the zipper stringer continuous manufacturing machine of the present invention has: a forming implantation part 1 for engaging elements; a feeder of the engaging element metal wire W that is intermittently fed to the forming implanting part 1 The apparatus 10; the fastener tape supply device 20 for intermittently supplying the fastener tape T to the above-mentioned molded implant part 1 by sending out the fastener stringer S; and the main shaft 30 rotationally driven by a motor.

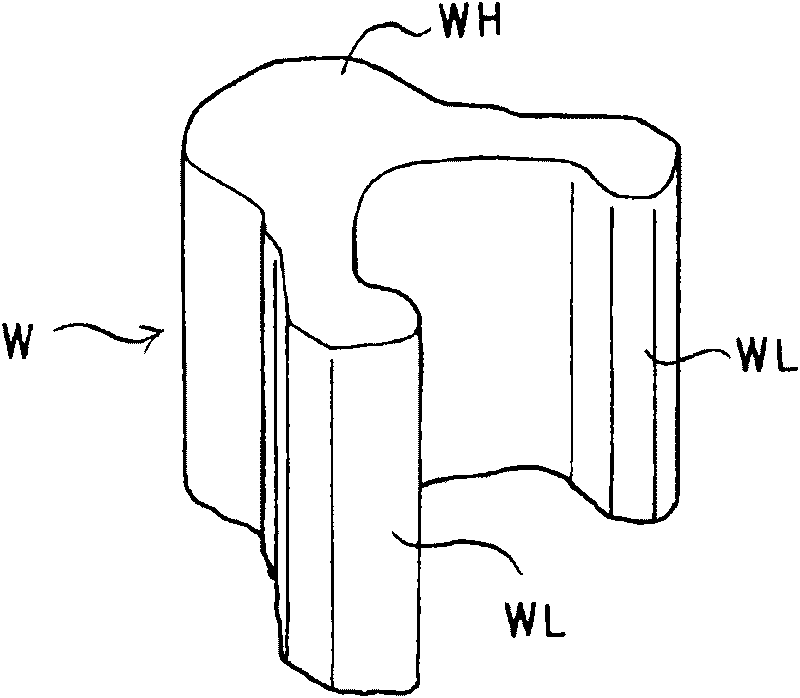

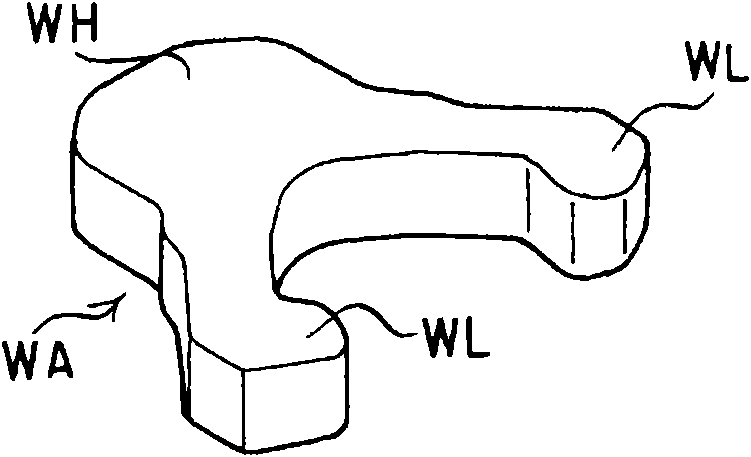

[0040] Such as figure 2 As shown, the above-mentioned metal wire W for engaging elements is a vertically long material having a head WH and a pair of legs WL and having a substantially Y-shaped cross section.

[0041] Such as figure 1 and Figure 6 As shown, the forming implant part 1 of the above-mentioned engaging element has: a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com