Partition board machine

A clapboard machine and clapboard technology, which is applied to paper/cardboard containers, carton/carton manufacturing machinery, containers, etc., can solve the problem of high operation control requirements of the cross clapboard machine, complex structure of the clapboard forming mechanism, and slow running speed. and other problems, to achieve the effect of improving stability and conveying efficiency, simplifying structure and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

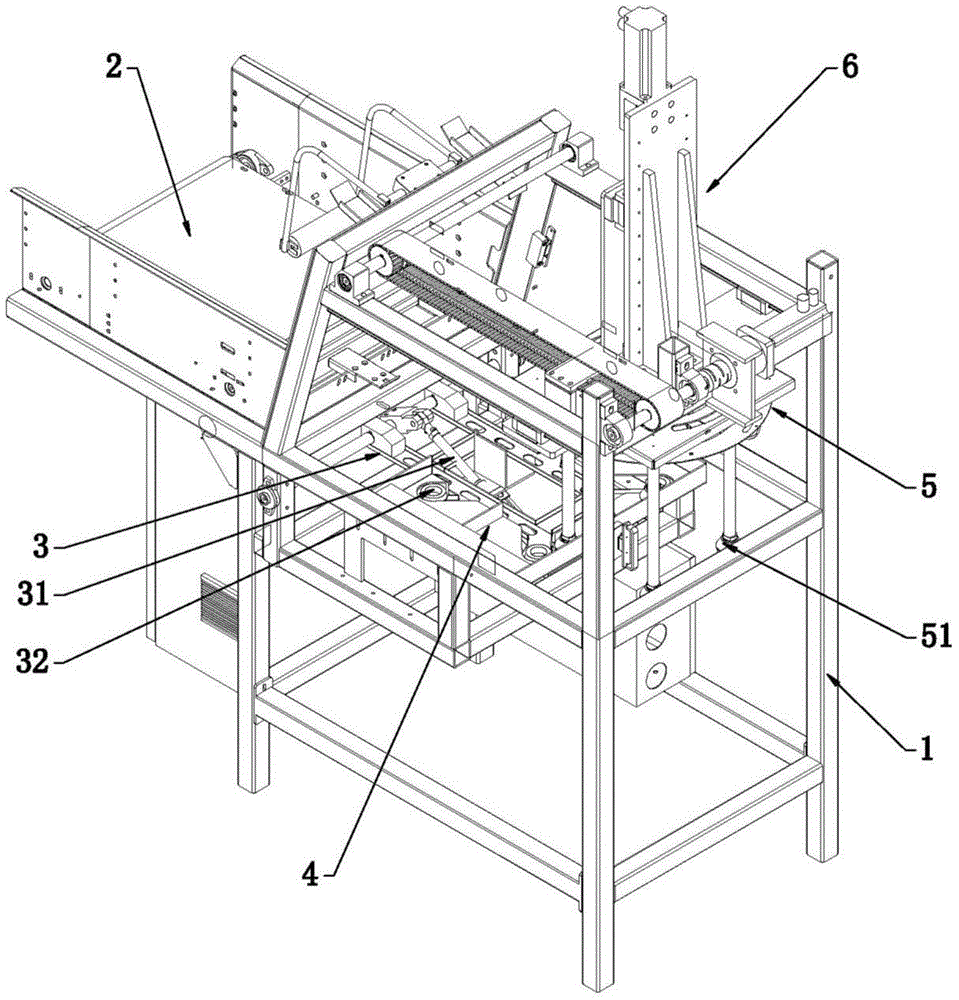

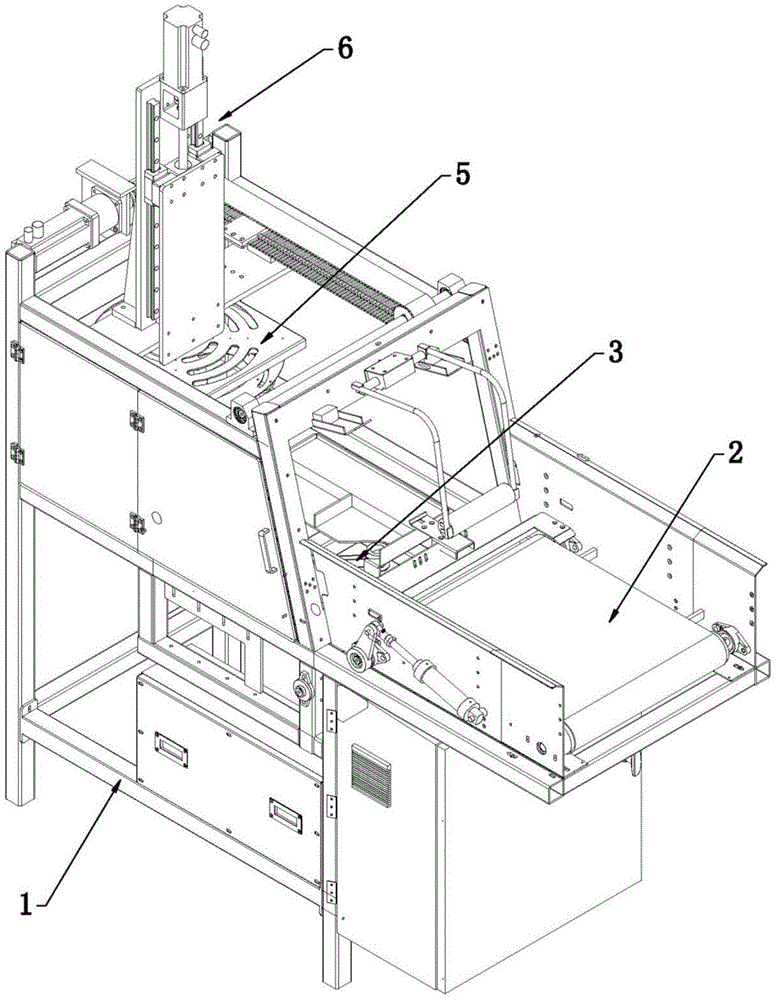

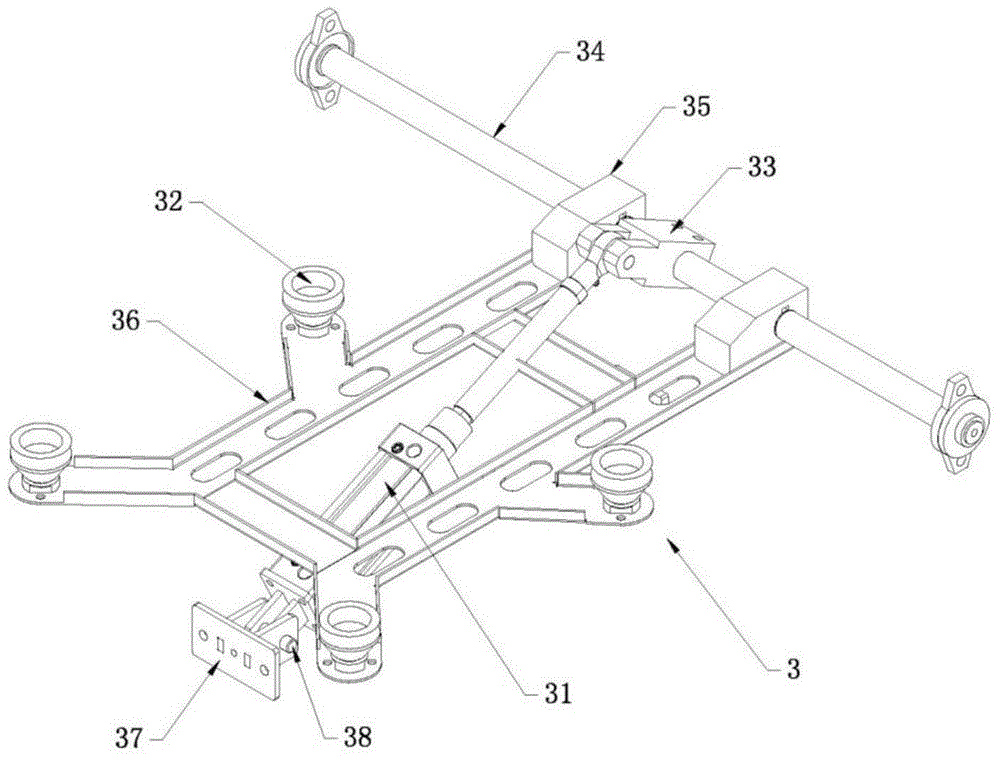

[0033] Such as Figure 1-2Shown: a partition machine, including a frame 1, a cardboard storage and delivery mechanism 2 is provided on the frame 1, and a puller mechanism 3 is provided on the side of the cardboard storage and delivery mechanism 2 in the conveying direction, and the puller in the puller mechanism 3 The arm cylinder 31 pushes the suction cup 32 of the pull arm to overturn and then pulls the unformed cardboard from the cardboard storage and delivery mechanism 2 and falls back to the preforming mechanism 4 so that the partition is preformed. The preformed partition is sucked up and the forming fixture 5 pushes the forming suction cup 51 through the forming cylinder 52 to synchronously drive the preformed partition to shrink inward so that the partition is formed, and the forming fixture 5 is driven by the conveying mechanism 6 to place the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com