Evaporative cooling and mechanical refrigeration compound water chilling unit

A chiller and evaporative cooling technology, applied in household heating, space heating and ventilation details, heating methods, etc., can solve the problems of limited use, difficulty in stabilizing the temperature of high-temperature cold water and meeting the specified requirements, and achieve temperature stability, Huge energy-saving potential and obvious energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

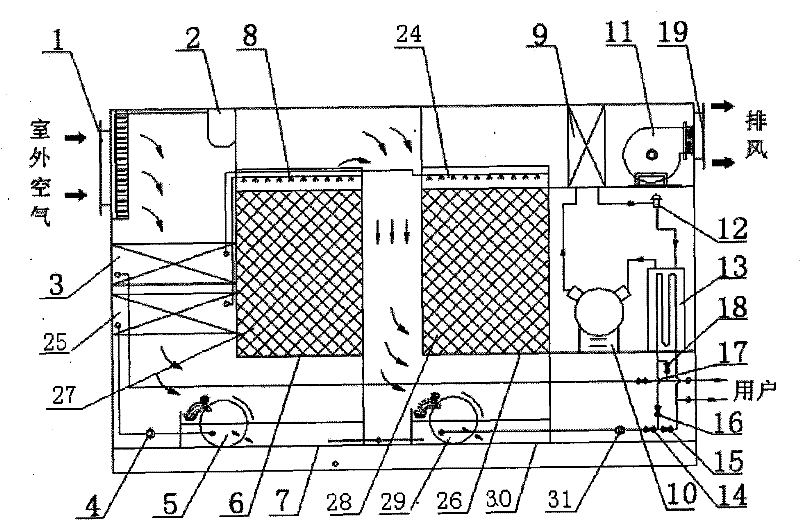

[0040] 1) The evaporative cooling cold water group is connected in series with mechanical refrigeration: open valve a14, close valve b15, open valve c16, close valve e18, open valve d17;

[0041] 2) The evaporative cooling chiller is used separately: close valve c16, open valve a14, open valve b15, open valve d17, close valve e18;

[0042] 3) The mechanical refrigeration chiller is used separately: open the valve e18, close the valve b15, and close the valve c16.

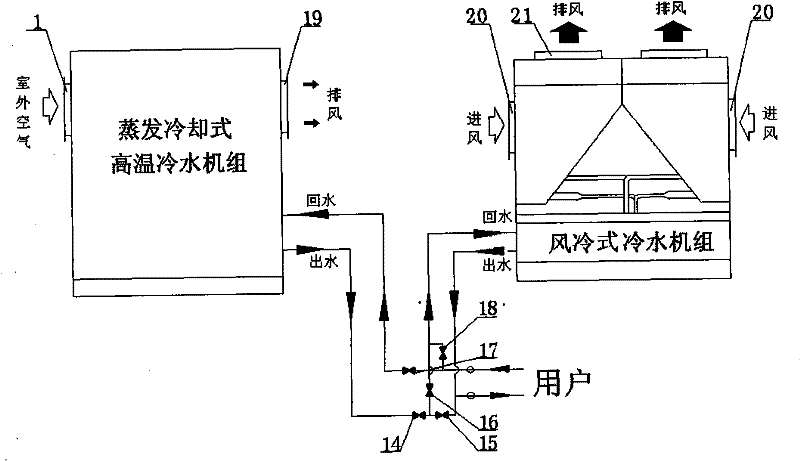

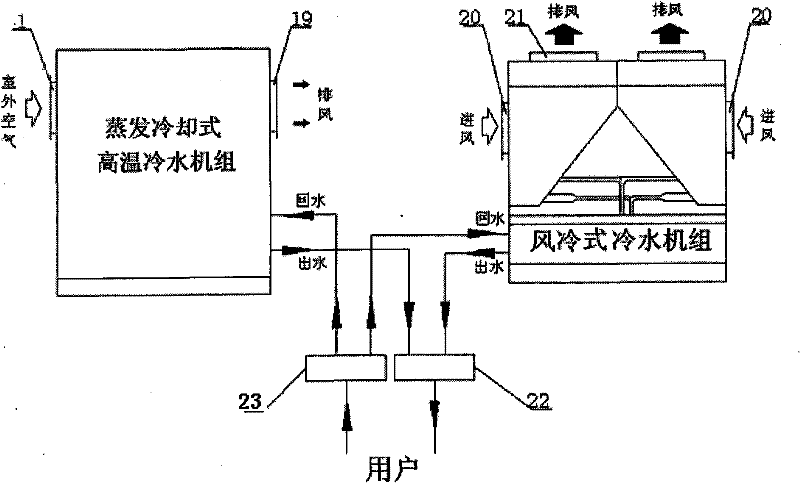

[0043] figure 2 It is an embodiment provided by the present invention in which the evaporative cooling water chiller and the air-cooled chiller are independently provided.

[0044] The air exhaust port of the evaporative cooling chiller is connected with the air inlet of the air-cooled chiller through a pipe, and the structure of the evaporative cooling chiller and the air-cooled chiller is as in Example 1, the evaporative cooling chiller and the air-cooled chiller Pipeline connection is also the same as embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com