Method for determining capillary radius distribution of flexible porous system by mass classification

A quality classification, capillary pore size technology, applied in the direction of suspension and porous material analysis, measurement devices, analysis materials, etc., to achieve the effect of preventing deformation of flexible voids and distortion of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

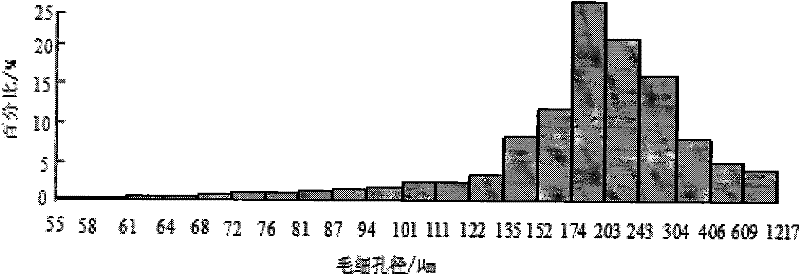

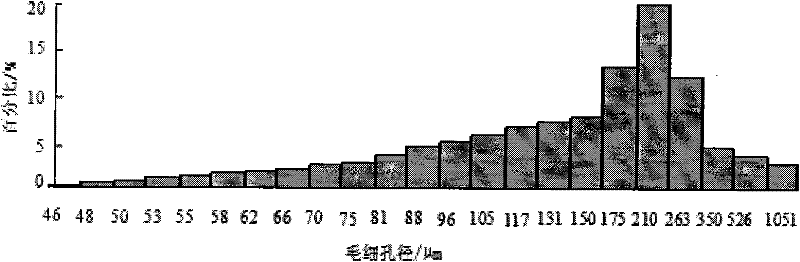

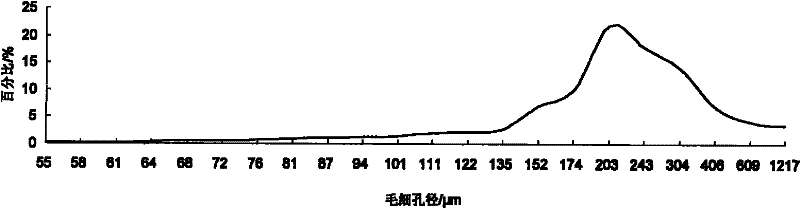

Image

Examples

Embodiment Construction

[0025] The method for measuring capillary pore size distribution of a flexible porous system using a quality classification method of the present invention comprises the following steps:

[0026] a. Prepare flexible porous system materials for measurement, the flexible porous system materials include woven fabrics, knitted fabrics, non-woven fabrics, leather and paper, and trim the samples to a length of 10-150±1cm and a width of 1.0-20±0.1 For a sample of cm, marks can be placed horizontally along the width of the sample at equal intervals of 0.2 to 10±0.1 cm from the lower end of the sample according to the test accuracy requirements;

[0027] b. Liquids prepared for measurement, including all liquids that wet the sample, that is, the contact angle of the liquid to the sample is less than 90 degrees;

[0028] c. Use detergent and / or organic solvent to remove the dirt on the sample, rinse and dry it, then hang it on the suspension device, keep the sample straight and vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com