Mass-classification-based device and method for measuring yarn capillary pore radius distribution

A technology of quality classification and capillary pores, which is applied in the directions of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of quantitatively characterizing wetting behavior, restricting dyeing, and post-finishing processing fabric heat and humidity. Comfort and other issues to achieve the effect of avoiding flexible gap deformation and result distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention are described in detail below. The present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

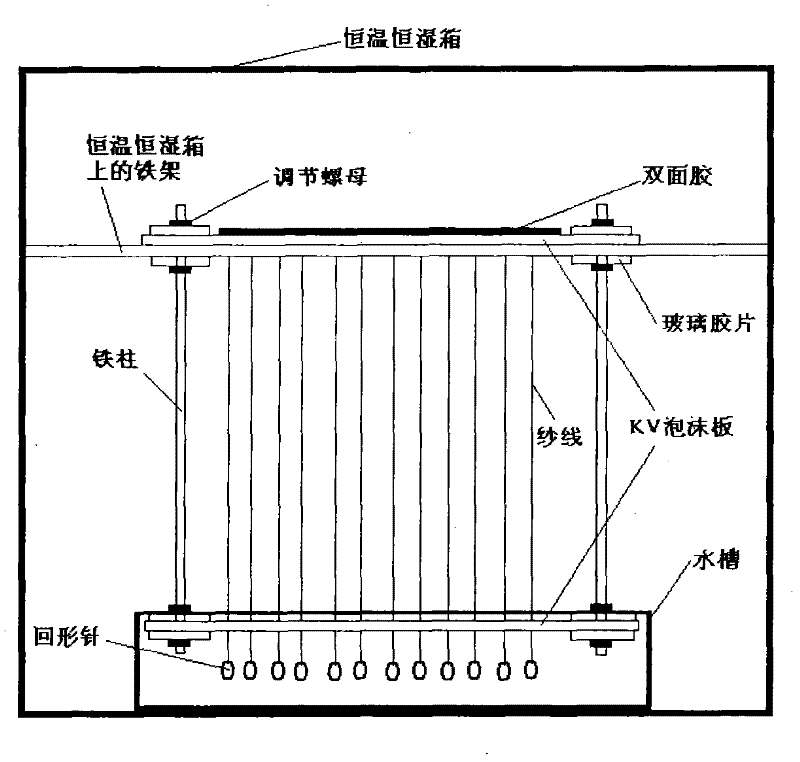

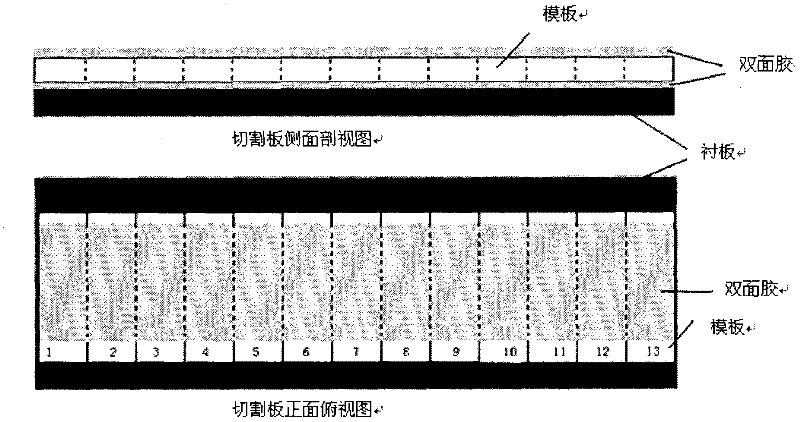

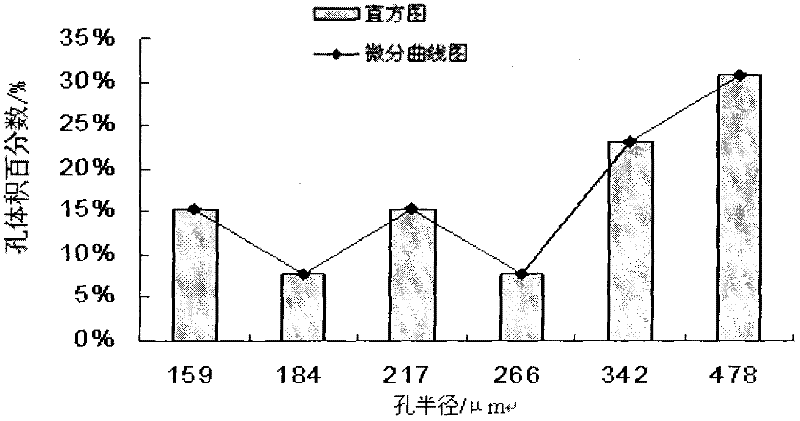

[0041] The present invention proposes a quality classification method and a matching device to measure the capillary pore size distribution of yarns, the device comprising: a yarn suspension rectangular frame device, a liquid tank and a yarn cutting plate, wherein:

[0042] The rectangular frame device is used to hang the yarn for wicking. The device consists of two rectangular rigid plates and four support columns. There are multiple parallel transparent grooves on the two plates. The width of the groove is larger than the diameter of the yarn. The distance between them should be as close as possible but capillary action canno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com