Ship square steel step die-pressing device

A compression molding device and marine technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of increased workload, large labor consumption, rework, etc., achieve precise machining linearity and angle, improve machining accuracy, height consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

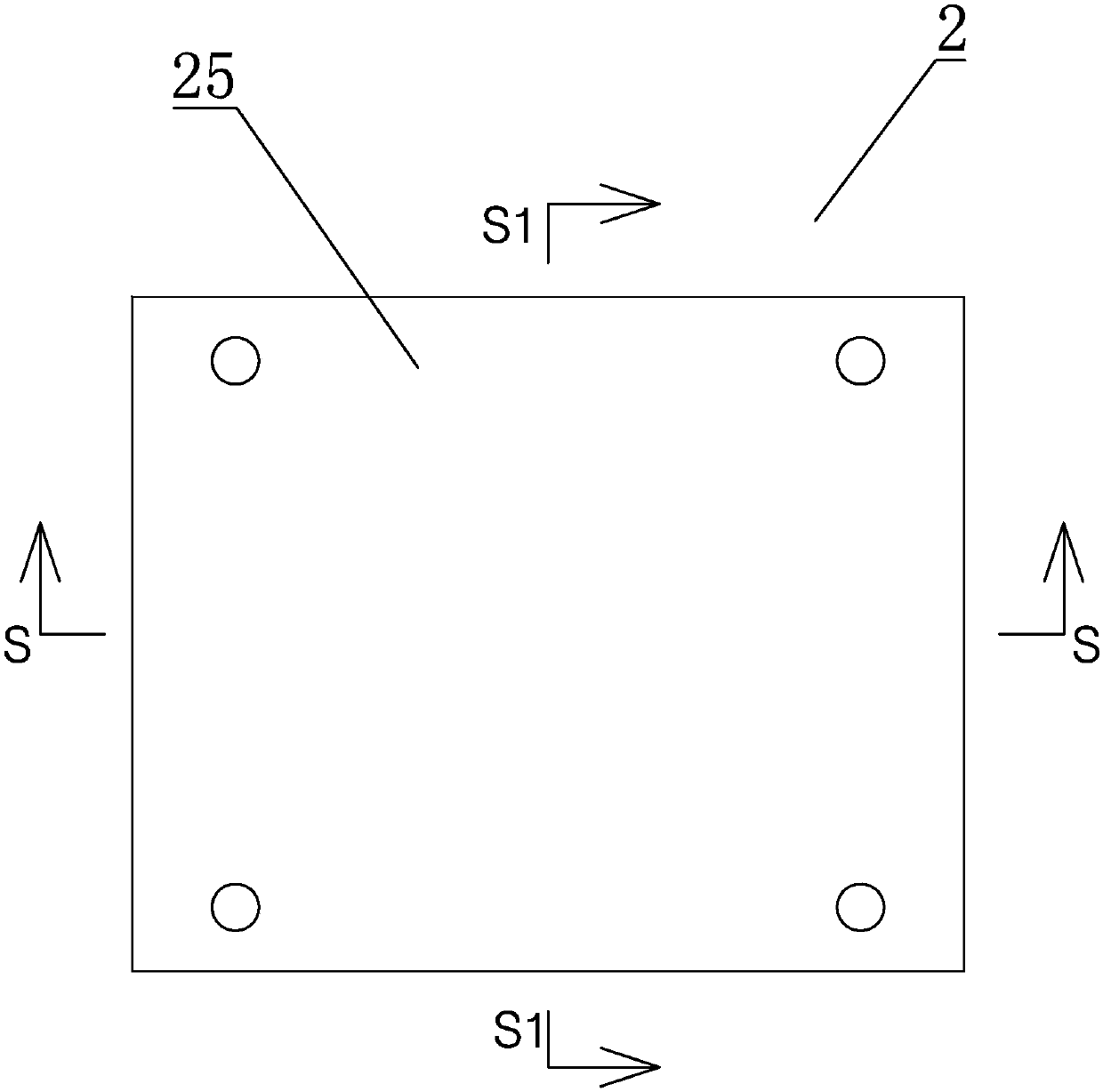

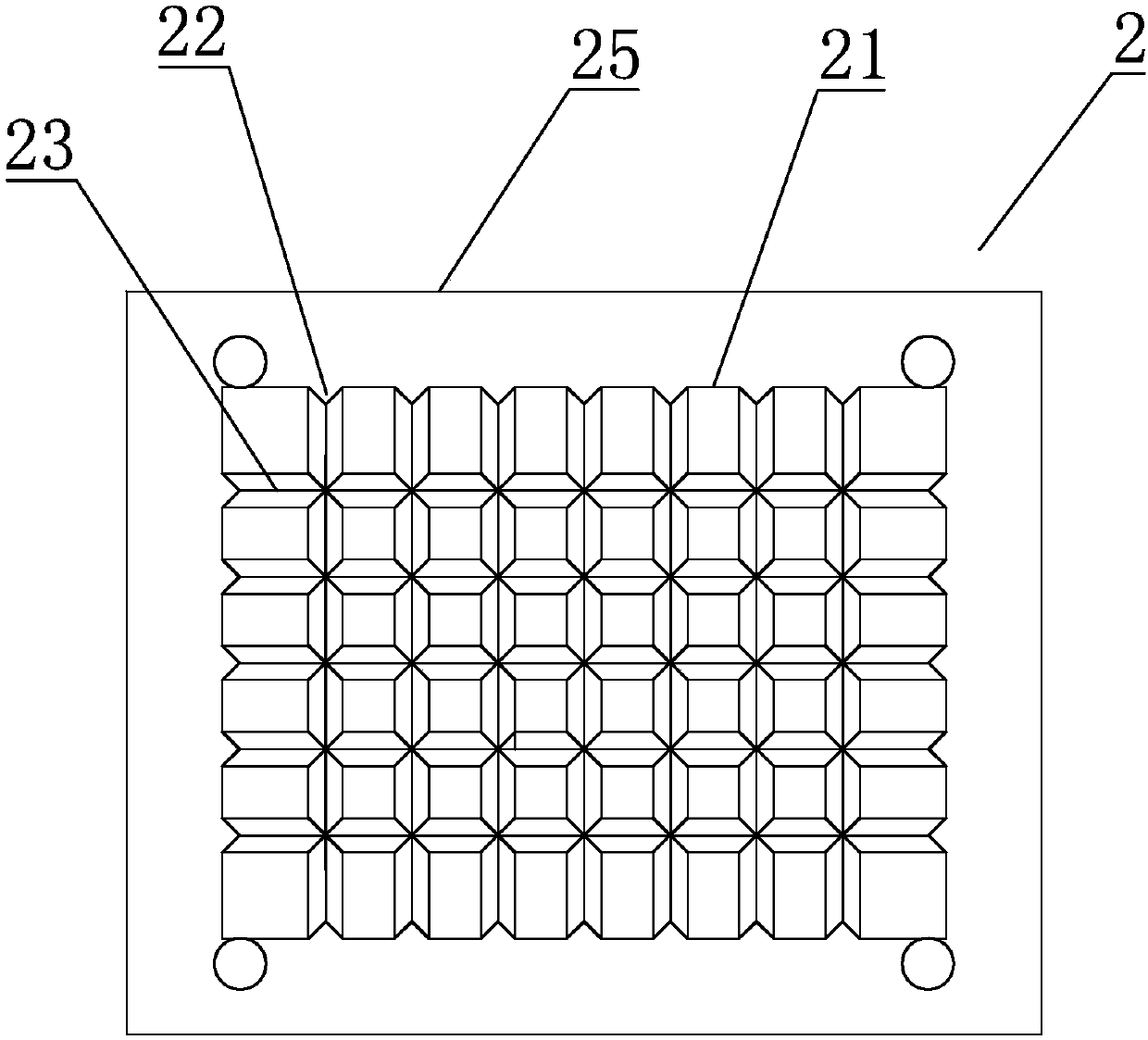

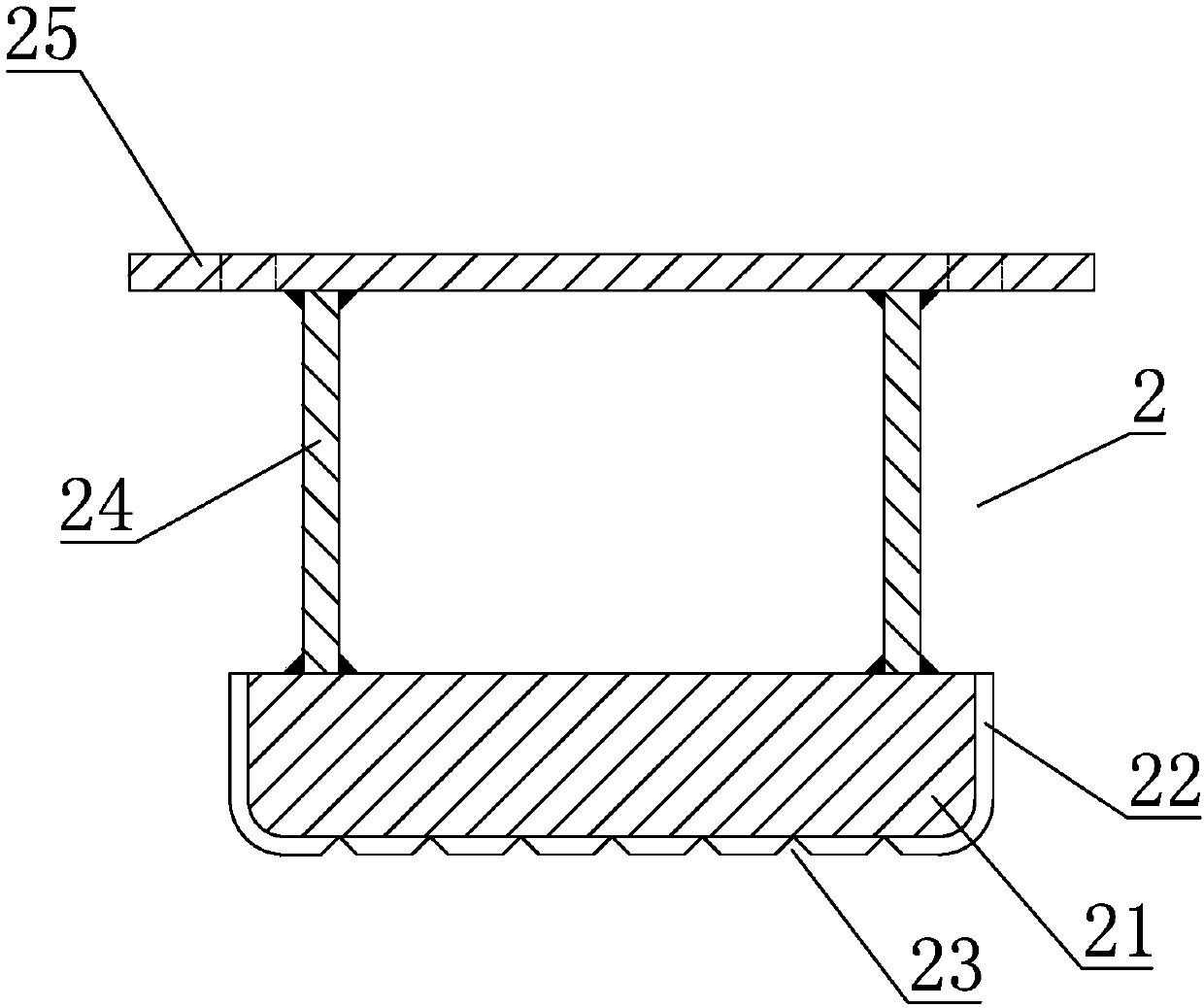

[0027] refer to Figures 1 to 4 , a marine square steel stepping die device, including a lower die 1 and an upper die 2, the lower die 1 is fixed on the lower die seat of the hydraulic press, a rectangular through hole 11 is opened in the middle of the lower die 1, and the upper die 2 includes a rectangular through hole 11 The matching punch 21 and the upper die top plate 25 are connected by the upper die reinforcement plate 24 between the punch 21 and the upper die top plate 25. The upper die reinforcement plate 24 includes four steel plates surrounded by a rectangle, and two adjacent The upper die reinforcing plate 24 is fully welded to ensure its strength. The upper die reinforcing plate 24 is welded to the lower side of the upper die top plate 25 in a full welding manner, and the punch 21 is also welded to the upper die reinforcing plate 24 in a full welding manner. lower end. The upper die top plate 25 is fixed below the upper die seat of the hydraulic press by bolts, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com