Glass cushion and preparation method

A technology of glass pad and glass powder, which is applied in the field of metal extrusion, can solve the problems of affecting the lubrication effect and the glass pad is fragile, and achieve the effects of reducing the scrap rate, preventing breakage, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

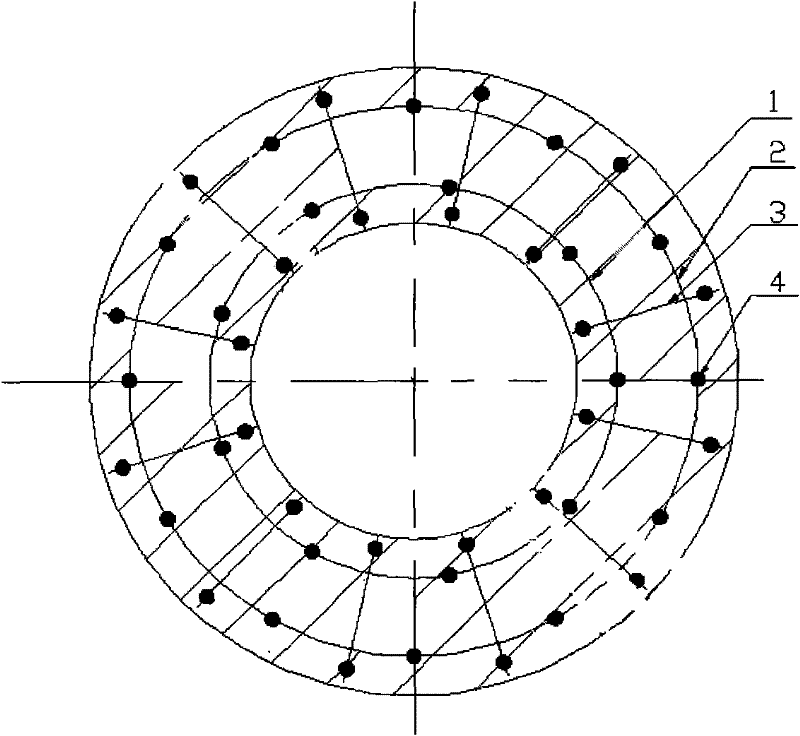

[0016] Prepare a glass mat 1 with an outer diameter of Φ1130 mm, an inner hole of Φ570 mm, and a height of 136 mm.

[0017] 1. Lajin preparation. The hemp ropes of Φ8mm-Φ10mm are used for the ties, and the hemp ropes 2 for the circumferential ties are placed at the inside of the size of the glass pad 1, and the outer diameter is 1 / 4 of the wall thickness. Tie a buckle 4 every 120mm; then according to the laying distance of the two circumferential tendon hemp ropes 2, determine that the length of the radial tendon hemp rope 3 is 210mm and tie a buckle 4 at both ends respectively.

[0018] 2. When making a glass mat: Take 130 kg of glass powder, add 9 kg of water glass to the glass powder, stir and mix evenly, pour the mixed material into the mold cavity, and when the pouring height reaches 56mm, place the Rope, press the prepared hemp rope figure 1 The position is placed well, that is, two circles of circumferential tension hemp rope 2 are placed at 1 / 4 wall thickness from th...

Embodiment 2

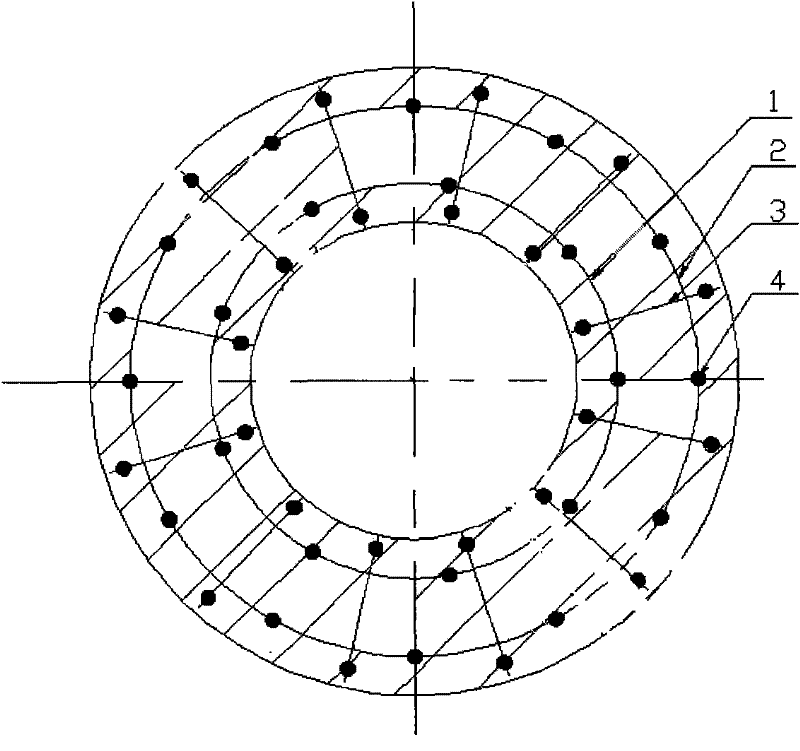

[0020] Prepare a glass mat 1 with an outer diameter of Φ1250 mm, an inner hole of Φ800 mm, and a height of 112 mm.

[0021] 1. Lajin preparation. Cotton ropes of Φ8mm-Φ10mm are used for the tension, and the circumferential cotton tension rope 2 is placed on the inside of the size of the glass mat 1, and the outer diameter is 1 / 3 of the wall thickness. The two circumferential tension cotton ropes 2 are 4200mm and 3325mm respectively. Tie a buckle 4 every 150mm; then according to the placement distance of the two circumferential tension cotton ropes 3, determine that the length of the radial tension cotton rope 3 is 185mm and tie a buckle 4 at both ends respectively.

[0022] 2. When making glass mat 1, take 150 kg of glass powder, add 10.5 kg of water glass to the glass powder, stir and mix evenly, pour the stirred glass powder into the cavity of the glass mat mold, and when it reaches 56mm, Press the prepared cotton cord figure 1 Placement, that is, place two circles of circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com