Pultrusion molding device for multi-layer structural product

A multi-layer structure, pultrusion molding technology, applied in the field of material processing, can solve problems such as coaxiality, hidden safety hazards, unreliable quality, etc., and achieve the effect of improving tensile strength and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0014] The multi-layer structural product pultrusion forming device provided by the present invention mainly prepares a multi-layer structural product by a pultrusion process, wherein each layer of the multi-layer structural product can be made of pultruded fiber, but not limited to fiber , It is also possible to choose raw materials with fiber pultrusion properties, and each layer of the multilayer structure product can be made by pultruding these materials. The present invention is only described by taking fiber material as an example.

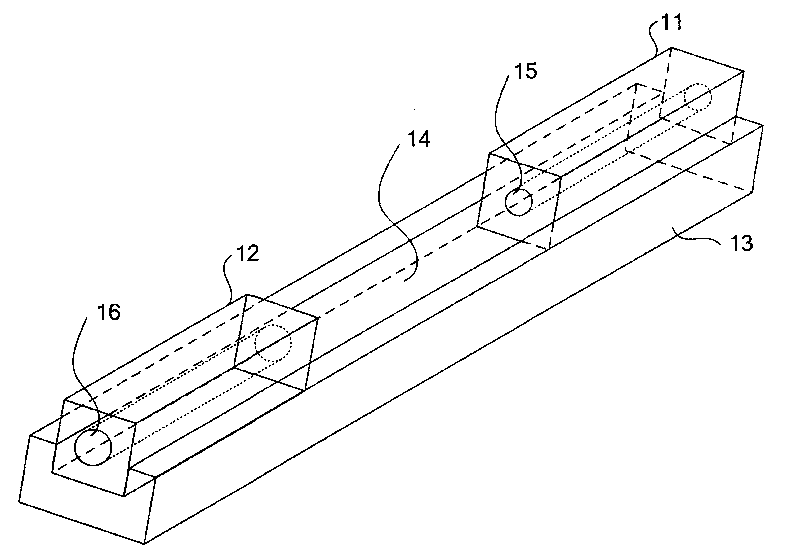

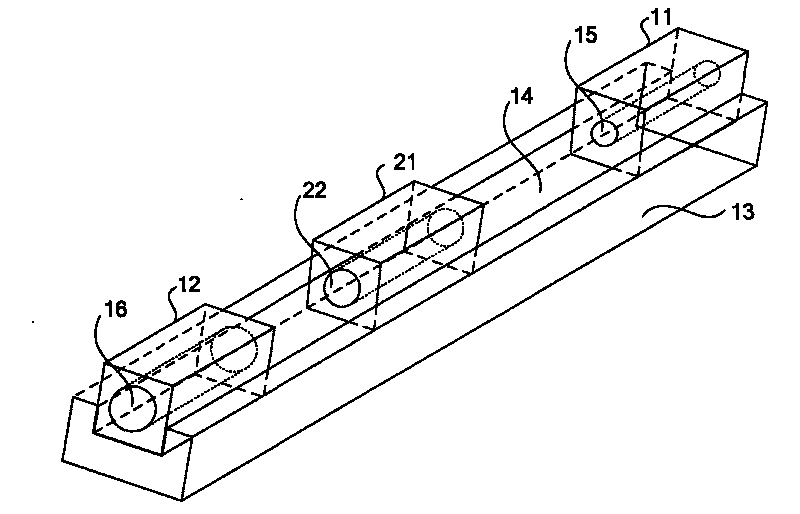

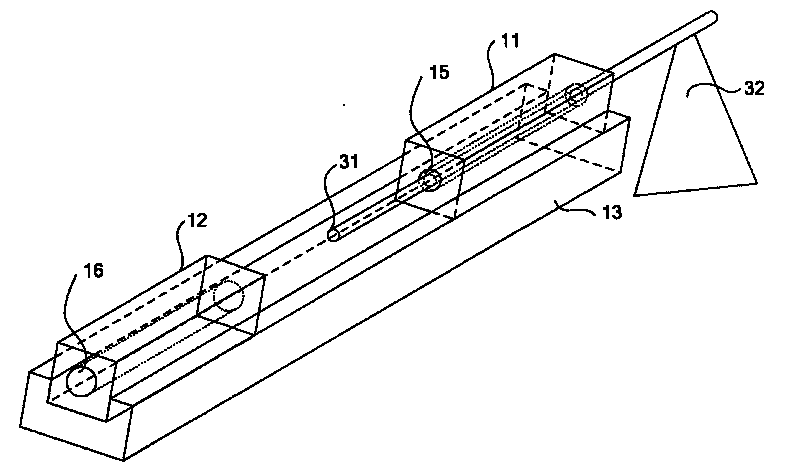

[0015] The first embodiment of the present invention is illustrated by a multi-layer structural product pultrusion forming device capable of pultruding inner and outer two-layer structural products. figure 1 It is a schematic diagram of the structure of the pultrusion device for mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com