Method of abutting joint of two total segments in shipbuilding process

A docking surface and hull technology, applied in ship parts, ship construction, ships, etc., can solve the problems of uneven structure of the docking panel mouth, excessive clearance, and excessive clearance, so as to reduce the workload of cutting and repairing the hull and improve the Docking accuracy and speed, reducing the effect of two positioning accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

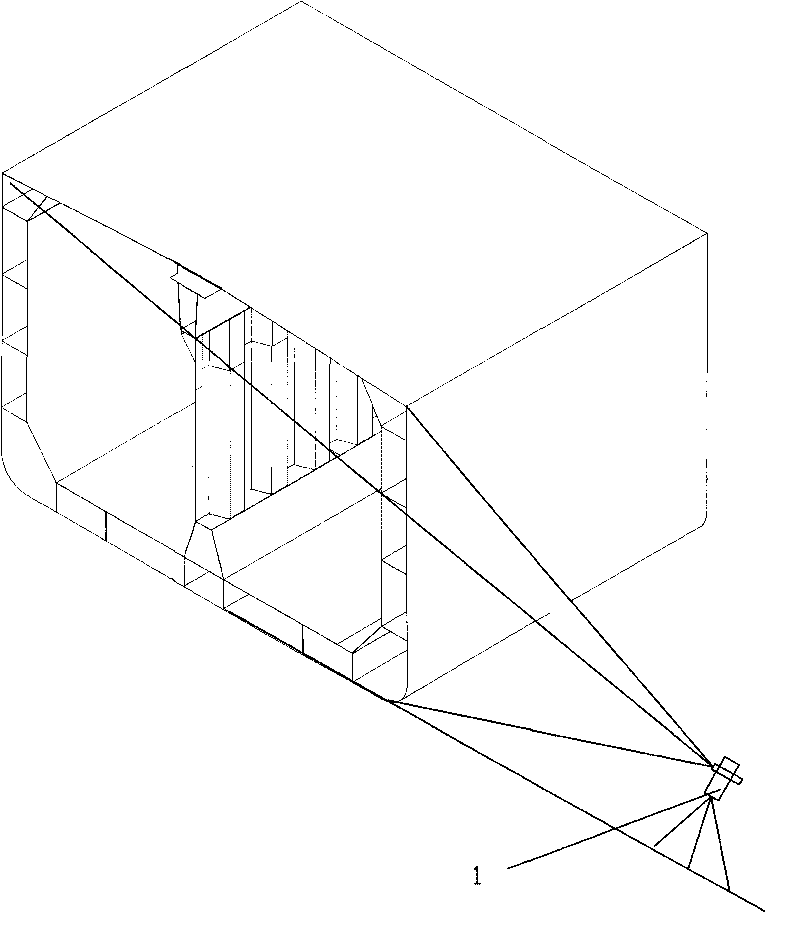

[0013] like figure 1 As shown, the laser theodolite is used to measure the flatness of the butt joint. First, the setting of the laser theodolite must be perpendicular to the center line of the hull. If the marking line detection is out of tolerance, it must be trimmed, and the excess part must be cut. Degree tolerance ≤ 2mm. figure 1 In , the selection surface of the lens of the laser theodolite should be orthogonal to the centerline of the hull.

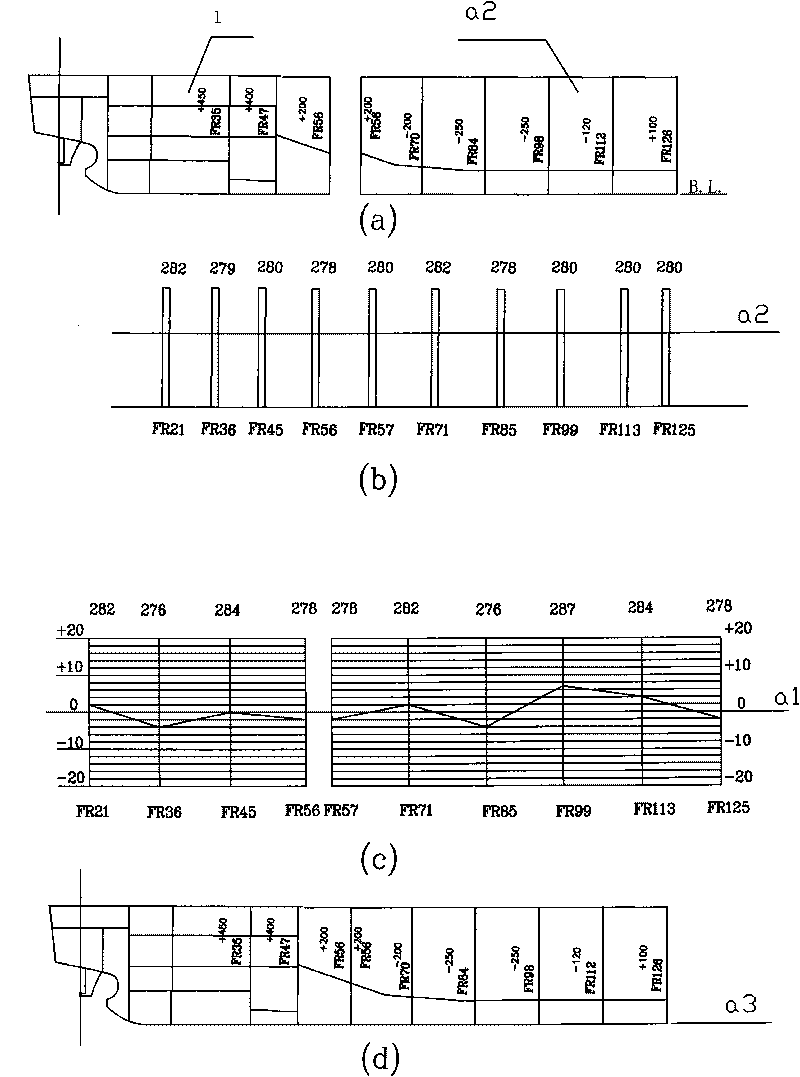

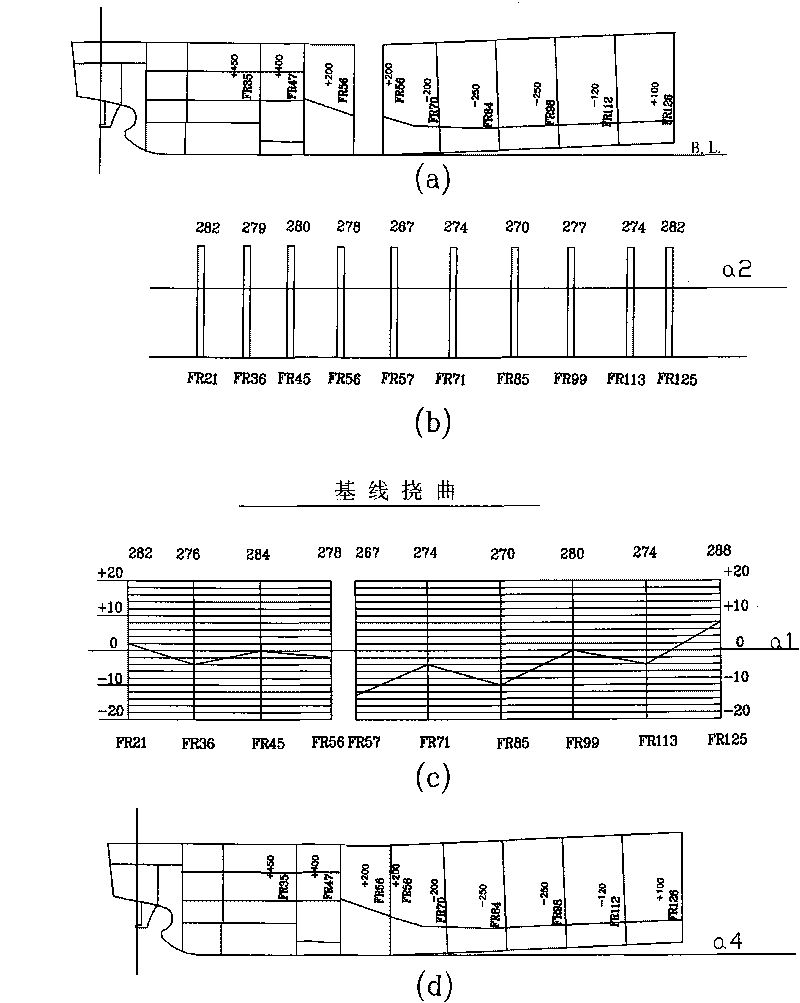

[0014] The same planarity measurement requirements of the joints of the general section of the present invention strictly control the same planarity of the seams of the first general section and the second general section. And measure the deflection of the base line at the bottom of the ship by using the base line on the closing pole, so as to determine the slope of the base line. When the slope of the baseline is zero, the upper surface of the pier shall be level before the floating positioning of the 2nd general section. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com