Electromagnetic fan clutch

An electromagnetic fan and clutch technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of single clutch control, can not meet the engine heat dissipation requirements, and is not conducive to improving fuel economy, so as to improve fuel economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

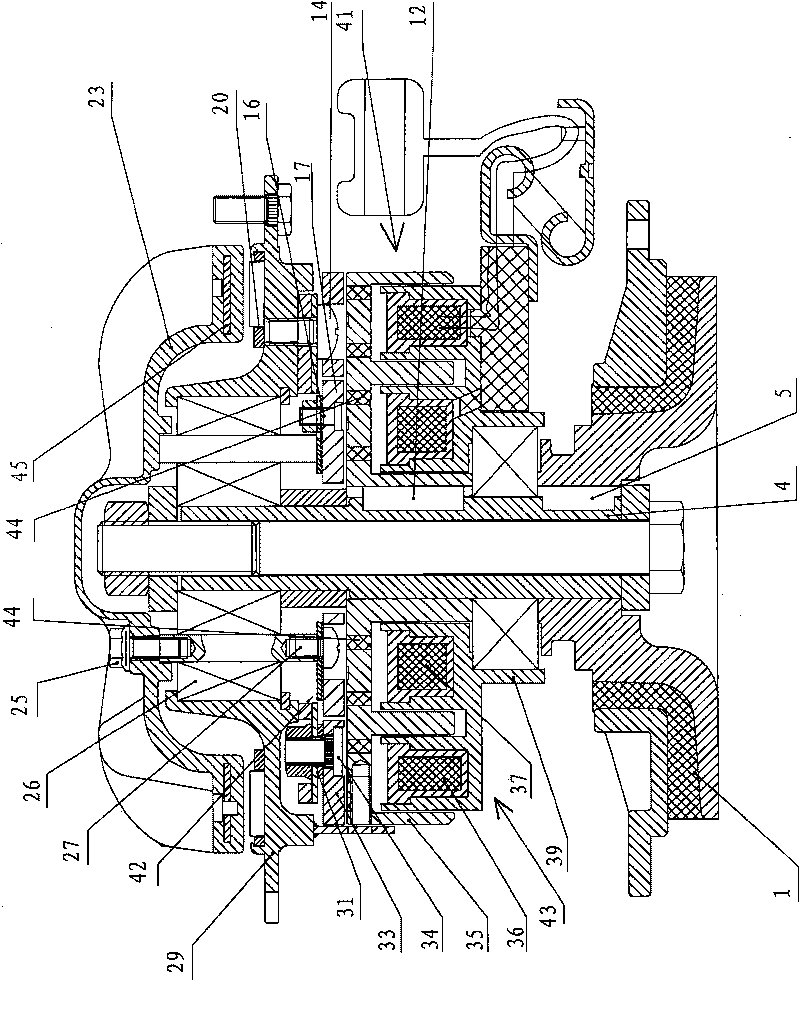

[0018] The specific structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

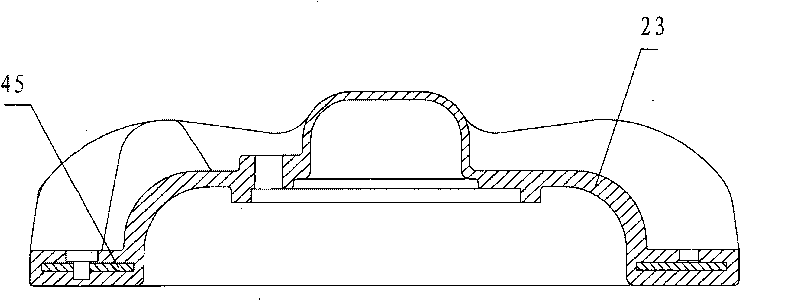

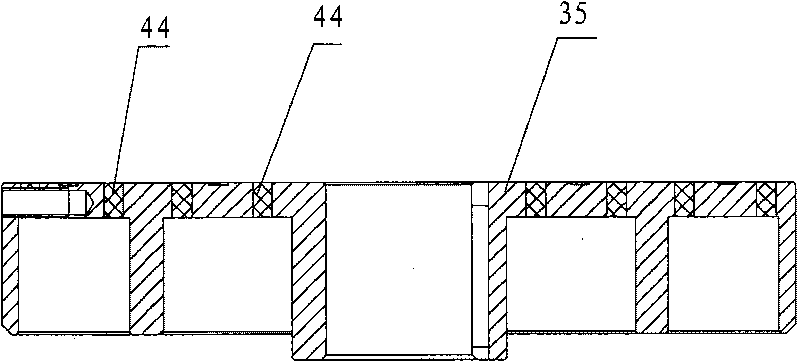

[0019] See attached Figure 1-3 As shown, an electromagnetic fan clutch realizes two-stage rotation speed conversion by using floating magnetic transmission and friction transmission, and mainly includes clutch rotor 41, clutch plate 42, excitation coil 43, fan base 29, transmission member 23, clutch rotor 41 has an electromagnetic coil seat 39 and an electromagnetic inductor 35 coaxially fixed with the rotating main shaft 4, the electromagnetic inductor 35 is located above the electromagnetic coil seat 39, and the clutch plate 42 includes a ring-shaped ring arranged along the radial direction of the clutch rotor 41. Inner clutch plate 17 and outer clutch plate 33, in attached figure 1 Among them, the inner clutch plate 17 and the outer clutch plate 33 are opposite to the electromagnetic inductor 35, and are located abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com