Built-in forced lubricating system of rocker arm of coal mining machine

A forced lubrication, built-in technology, used in the field of lubrication systems, can solve the problems of reduced service life, lack of lubrication of bearings and gears, wear of gears and bearings, etc., to achieve the effect of improved service life and good lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

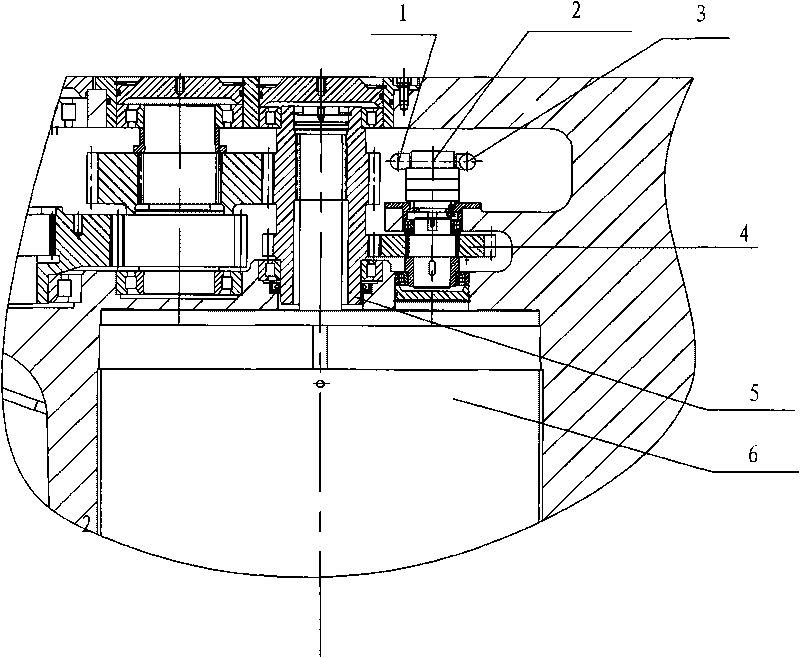

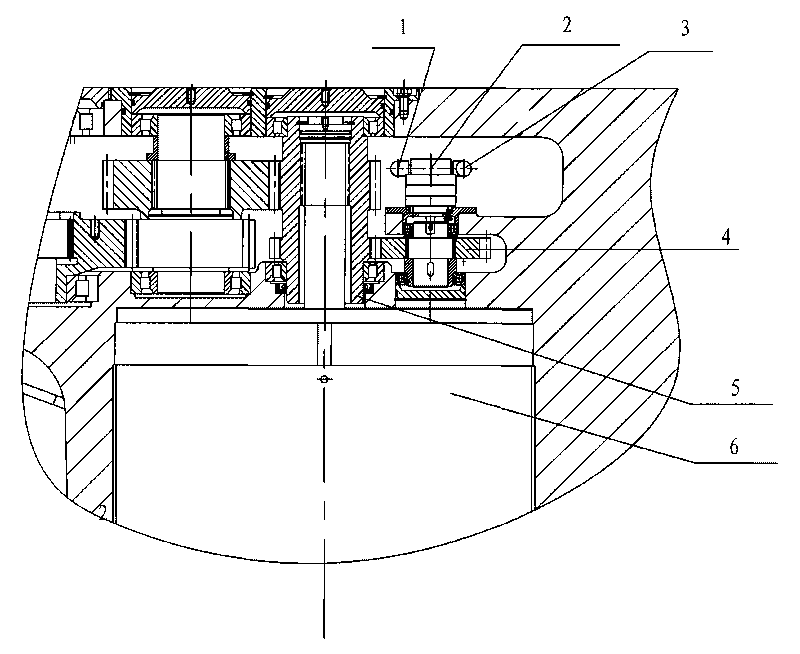

[0008] The spline shaft of the original motor 6 is connected with the spline in the driving gear 5, and a forced lubrication gear pump 2 is added in the rocker arm. Driving gear 5 meshes. The oil suction port 1 of the gear pump 2 is connected to the oil pool in the inner cavity of the rocker arm, and the oil outlet 3 is connected to the oil pipe to deliver to the lubrication point to realize the forced lubrication of the rocker arm. The rocker arm motor of the coal mining machine rotates, and the driving gear, driven gear and gear pump rotate in turn, and the lubricating oil is sent to the gear and bearing of the head at the upper end of the rocker arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com