Method and system for monitoring and analyzing energy consumption in operated chemical plants

一种运行中、化工厂的技术,应用在通用控制系统、测试/监控控制系统、控制/调节系统等方向,能够解决不能改善管理、未提供等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

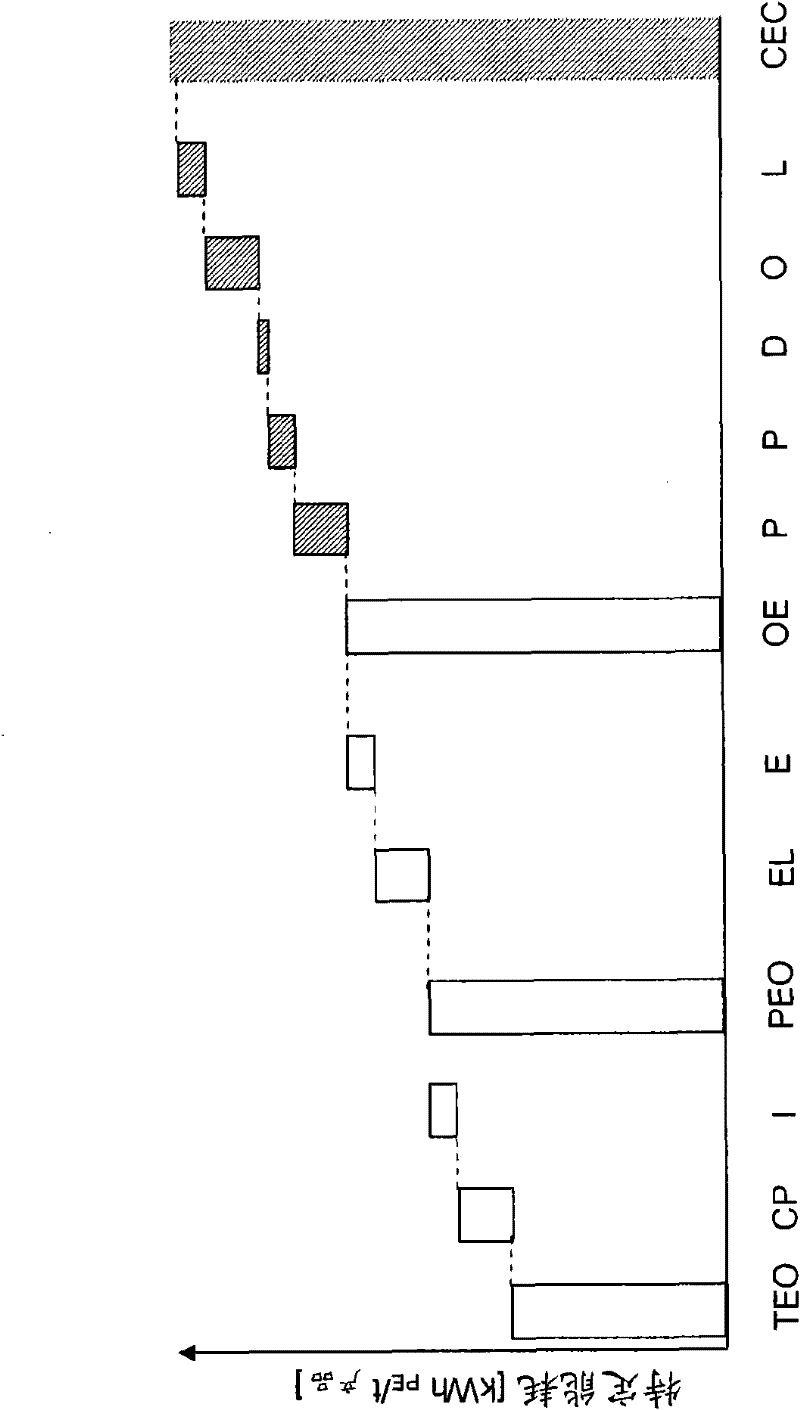

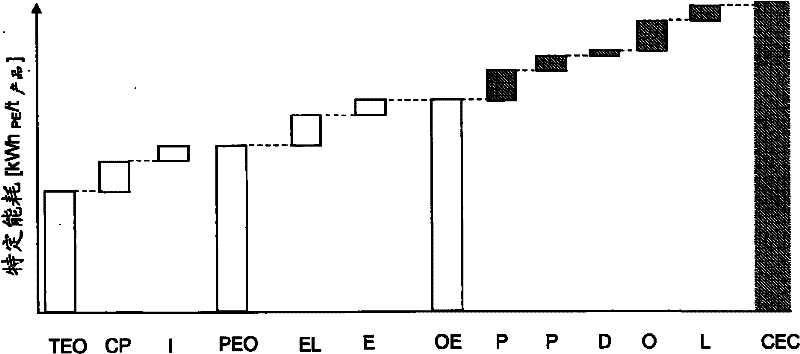

[0073] figure 1 A schematic diagram showing the energy consumption cascade provided by an embodiment of the proposed method for monitoring and analyzing energy consumption of an operating chemical plant is shown. figure 1 The shown energy steps are represented as histograms starting from the theoretical energy consumption optimum value TEO and by adding the previously provided, previously retrieved individual parameters in groups corresponding to the previously identified parameters The energy consumption rate as the energy cascade reaches the current energy consumption CEC of the plant in basic operation. Firstly, the parameters that contribute to the increase in energy consumption of the plant relative to the plant type-specific theoretical energy consumption optimum TEO are identified and grouped accordingly according to their corresponding sources. The energy consumption in figure 1 is expressed in terms of kWh PE / t 产品 The specific energy consumption, where the indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com