Energy-saving systems and anti-swing energy-saving crane provided with same

An energy-saving system, crane technology, applied in transportation and packaging, load hanging components, etc., can solve the problems of gravitational potential energy burning, waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

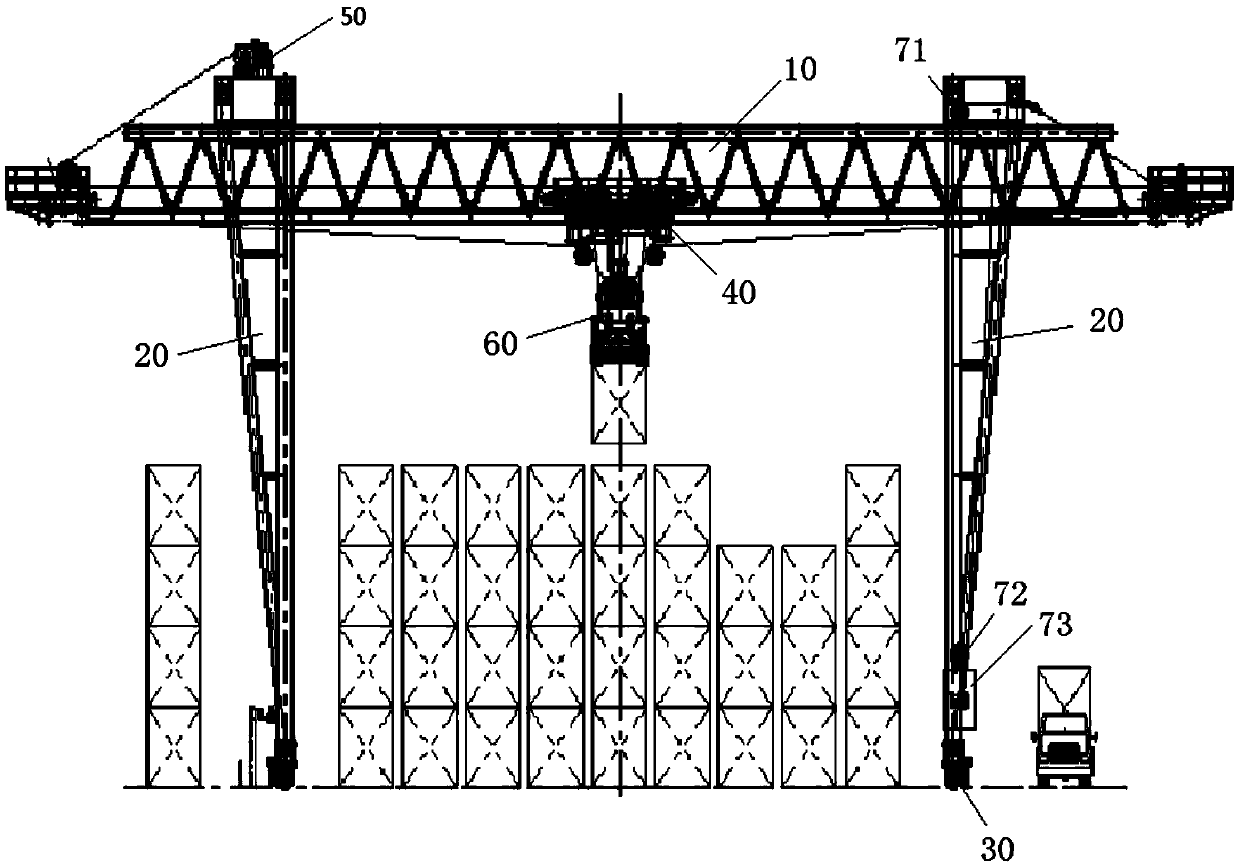

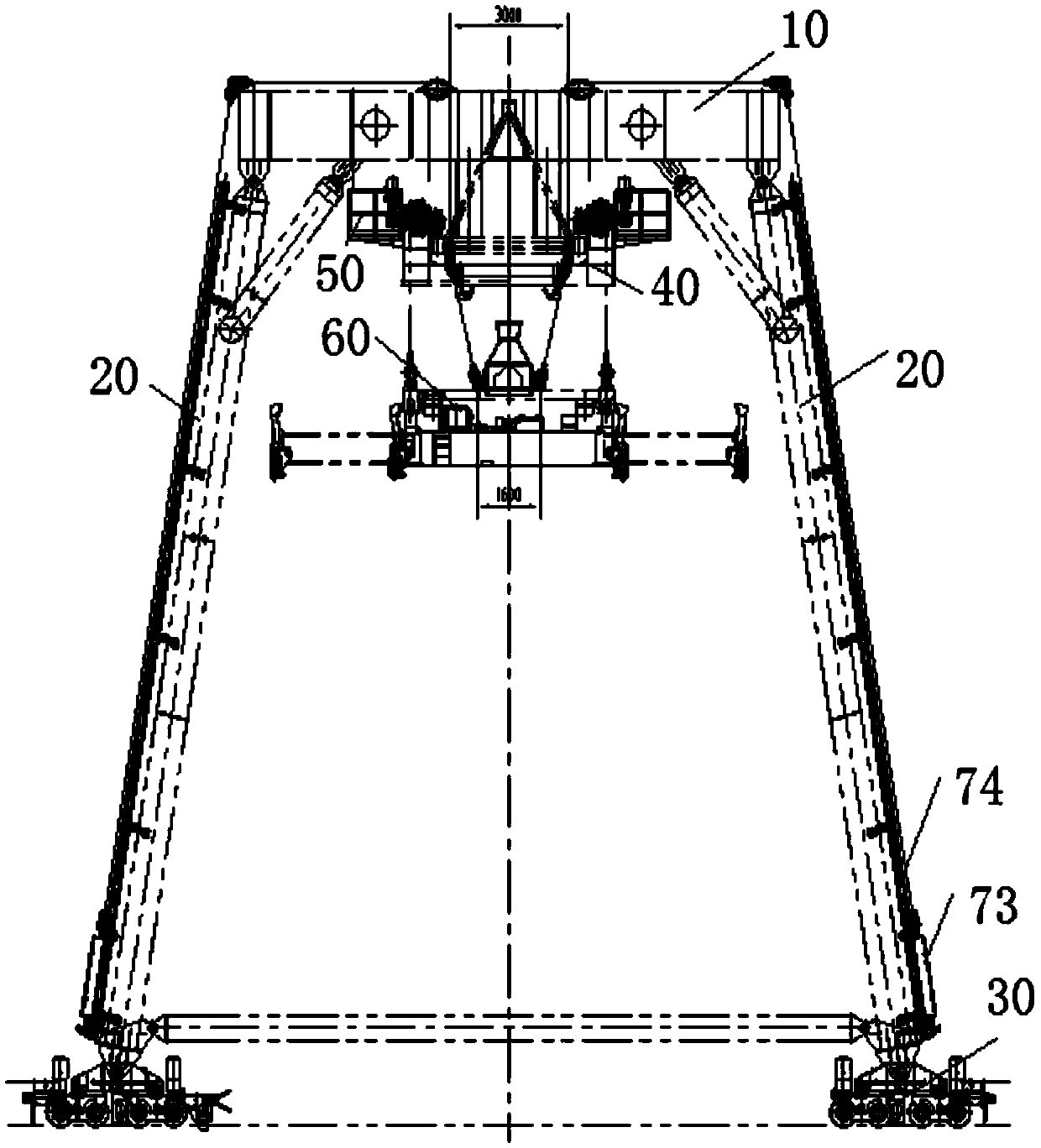

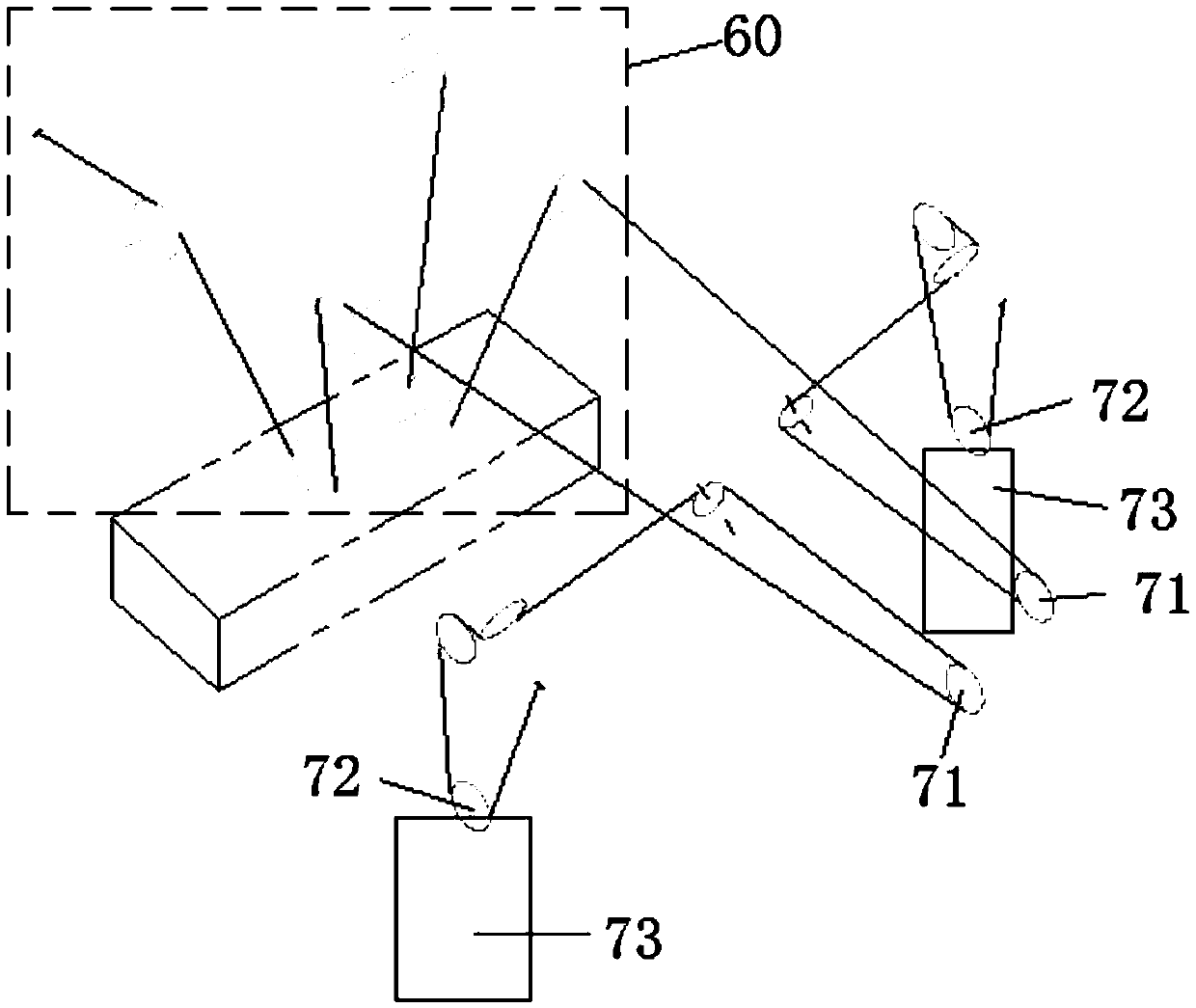

[0021] Such as Figure 1-2 As shown, the present invention will be described in detail by taking a simple form of anti-sway crane as an example. 40. Lifting mechanism 50 and anti-sway spreader system 60. The operator controls the front and rear movement of the cart traveling mechanism 30 on the ground and the left and right movement of the trolley traveling mechanism 40 on the main beam, so that the lifting mechanism 50 can drive the anti-sway spreader system 60 to move up and down to grab the container at any position. Realize the handling function. The above-mentioned metal frame, cart traveling mechanism 30, trolley traveling mechanism 40, hoisting mechanism 50, steel wire rope, pulley bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com