Nonmagnetic toner

一种调色剂、非磁性的技术,应用在显影剂、仪器、光学等方向,能够解决不利熔融粘附构件污染、不能改进定影特性、难以实现调色剂低温定影性相容性等问题,达到转印性能优良、摩擦带电特性的变化小、高品质图像的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

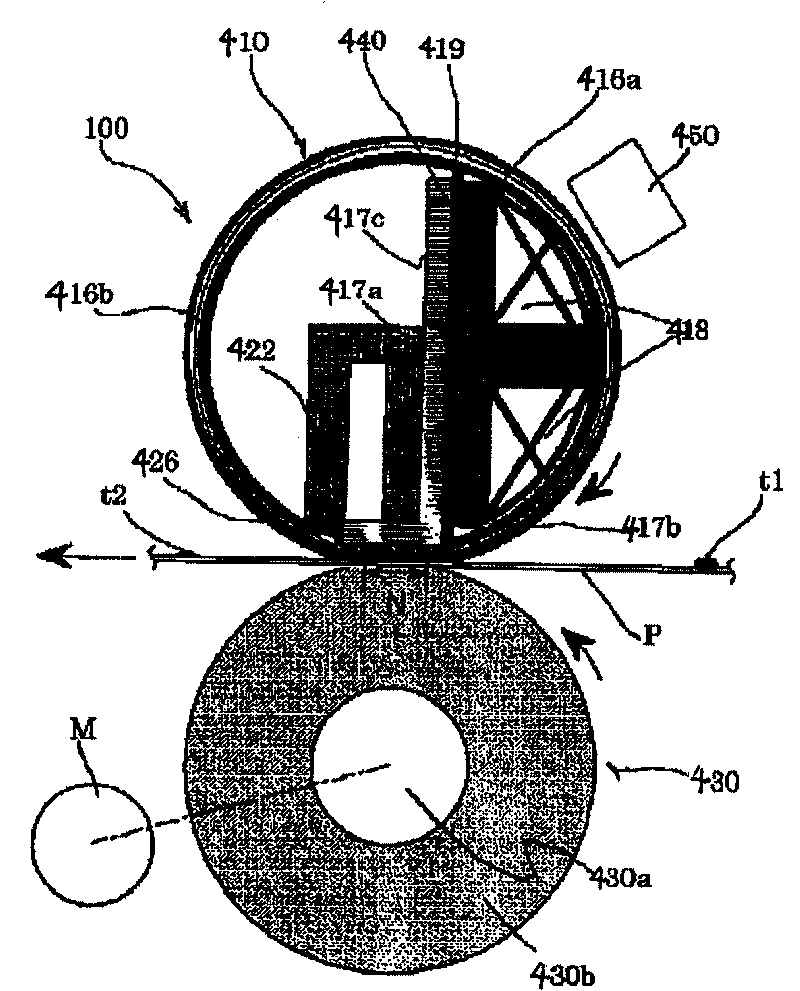

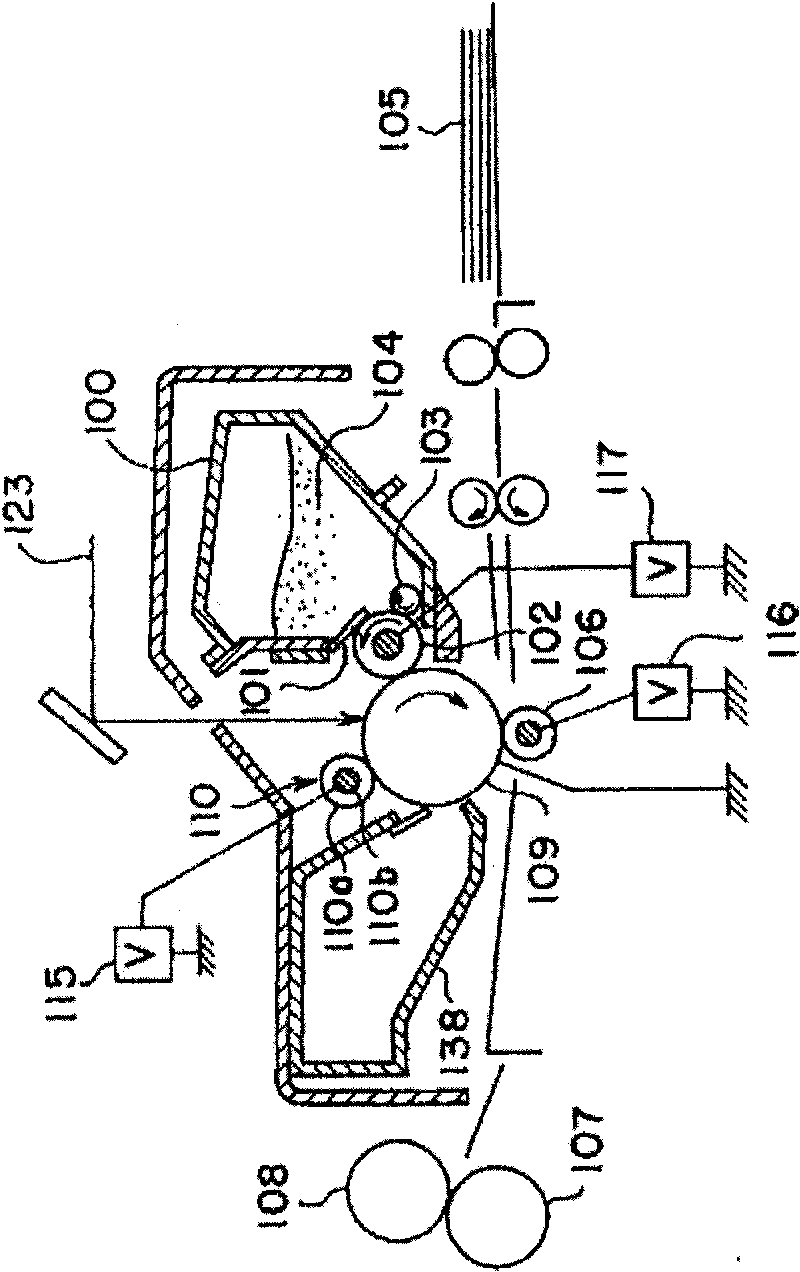

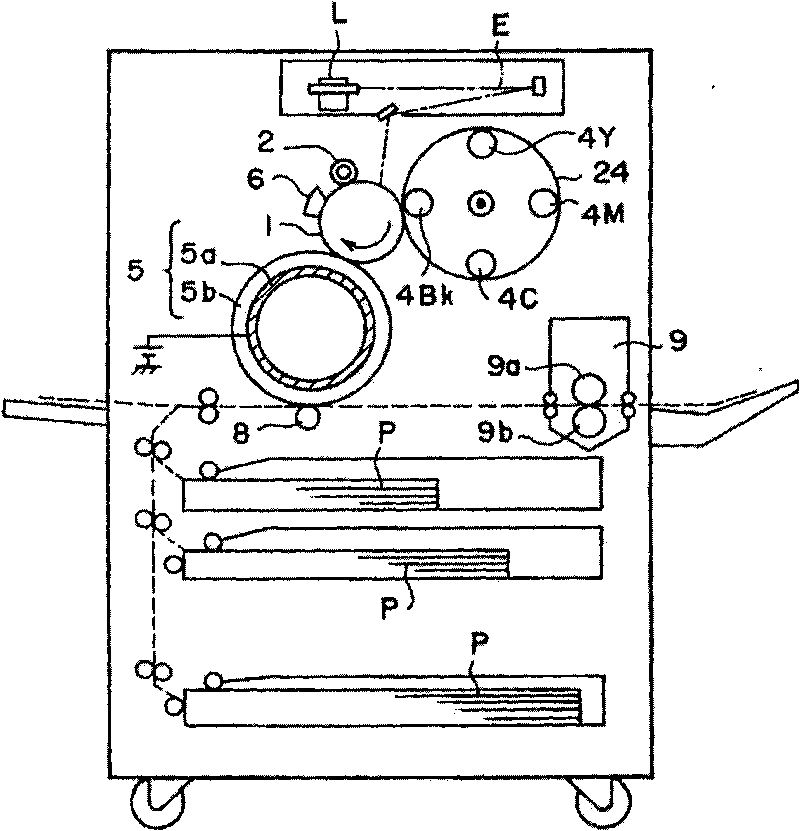

Method used

Image

Examples

Embodiment 1

[0358] (Preparation of aqueous dispersion medium)

[0359] 350 parts of water

[0360] Tricalcium Phosphate 3 parts

[0361] While maintaining the temperature of the mixture of the above-mentioned components at 60° C., the mixture was stirred at a speed of 12,000 rpm with a high-speed stirring device TK-homogenizer, thereby preparing an aqueous dispersion medium.

[0362] (Preparation of Polymerizable Monomer Composition 1)

[0363] Styrene 65 parts

[0364] C.I. Pigment Blue 15:3 5 parts

[0365] Negative charge control agent (3,5-di-tert-butyl aluminum salicylate compound) 1 part

[0366] A monomer mixture 1 was prepared by dispersing the above formulation at room temperature for 5 hours with a fine grinder.

[0367] Subsequently, the monomer mixture 1 was added into a stirring tank capable of controlling the temperature, and its temperature was raised to 60°C.

[0368] Next, 10 parts of Fischer-Tropsch wax (having the highest endothermic peak at 75° C.) was added to t...

Embodiment 2

[0454] Cyan toner No. 2 was obtained in the same manner as in Example 1 except that the amount of polar resin used was changed to 40 parts. Table 1 shows the physical properties of the toner, and Table 2 shows the evaluation results.

Embodiment 3

[0456] Cyan toner No. 3 was obtained in the same manner as in Example 1 except that the polar resin usage amount was changed to 10 parts. Table 1 shows the physical properties of the toner, and Table 2 shows the evaluation results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com