Non-return device of chain belt of pig machine

A non-return device, cast iron machine technology, applied in foundry, foundry equipment, pig iron foundry and other directions, can solve the problems of falling back slip damage, production stoppage, and the chain belt of cast iron machine is prone to breakage, etc., and achieves the effect of preventing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

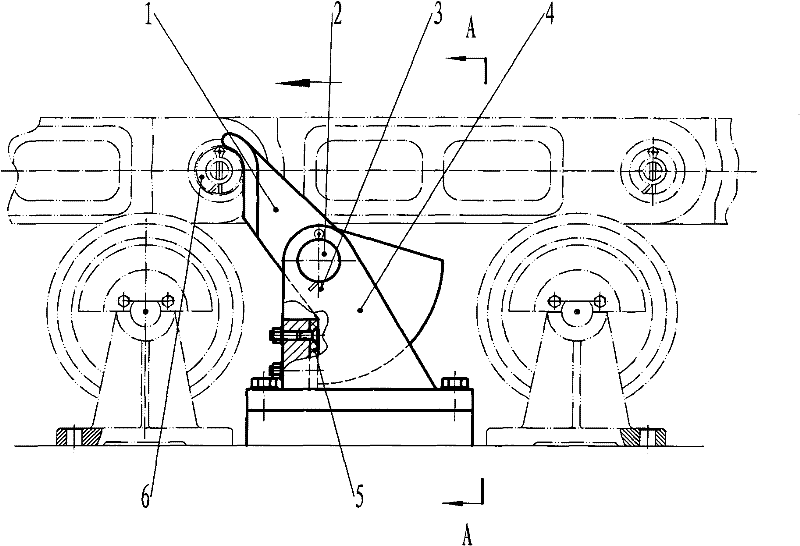

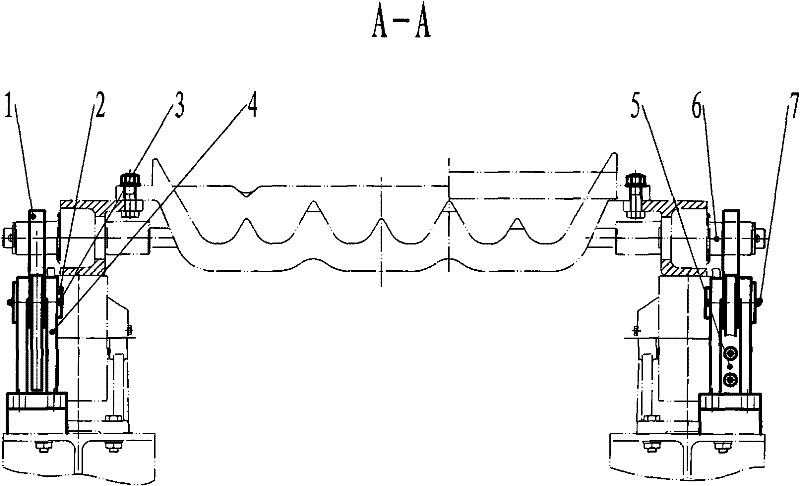

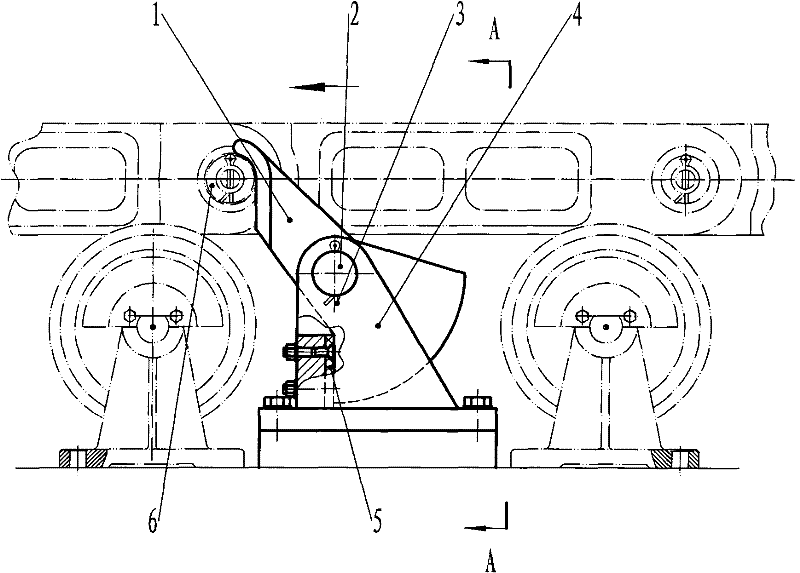

[0012] The cast iron machine chain belt non-return device is installed under the two ends of the upper chain belt of the cast iron machine, and is installed symmetrically in pairs. Generally, 2 to 8 pairs of non-return devices for chain belts are installed symmetrically at a certain distance for each chain belt, and the first pair is installed near the driving wheel.

[0013] As shown in the figure, the cast iron machine chain belt non-return device is composed of a baffle plate 1, a support shaft 2, a support seat 4 and a stop pad 5 and the like. The baffle plate 1 is installed in the middle of the support shaft 2, and the upper arc end of the baffle plate 1 is stuck on the end of the shaft sleeve 6 of the chain belt; the support shaft 2 is supported by the support holes of the left and right side plates of the support seat 4, and the shaft end can be set Axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com