Check valve and novel fuel cell stack using same

A check valve and check technology, applied in the field of new fuel cell stacks, can solve the problems of obvious pressure drop, small check valve flow, large flow resistance, etc., and achieve the effect of small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

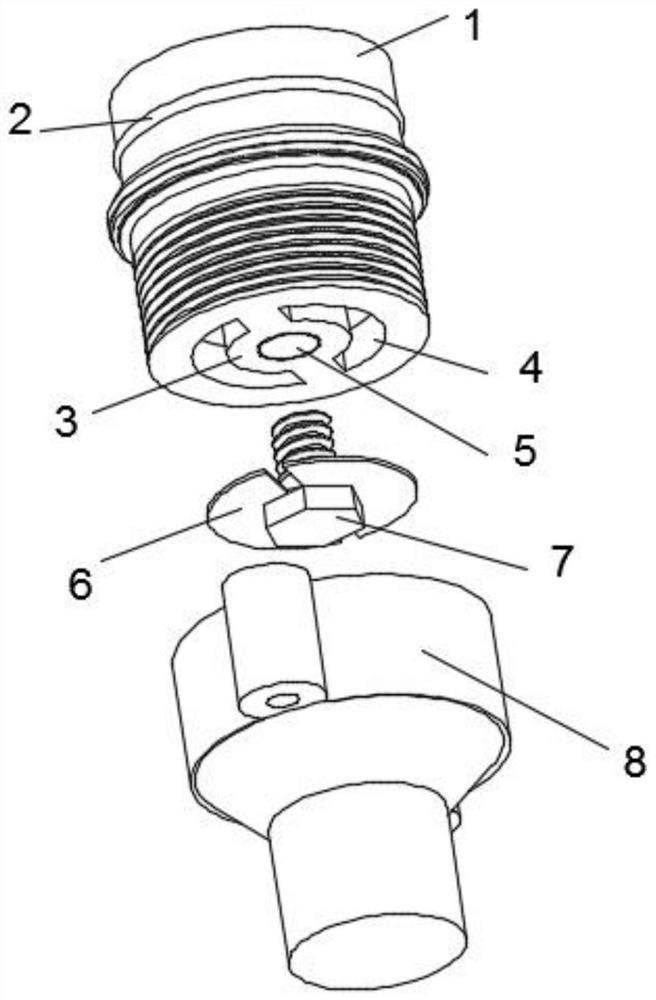

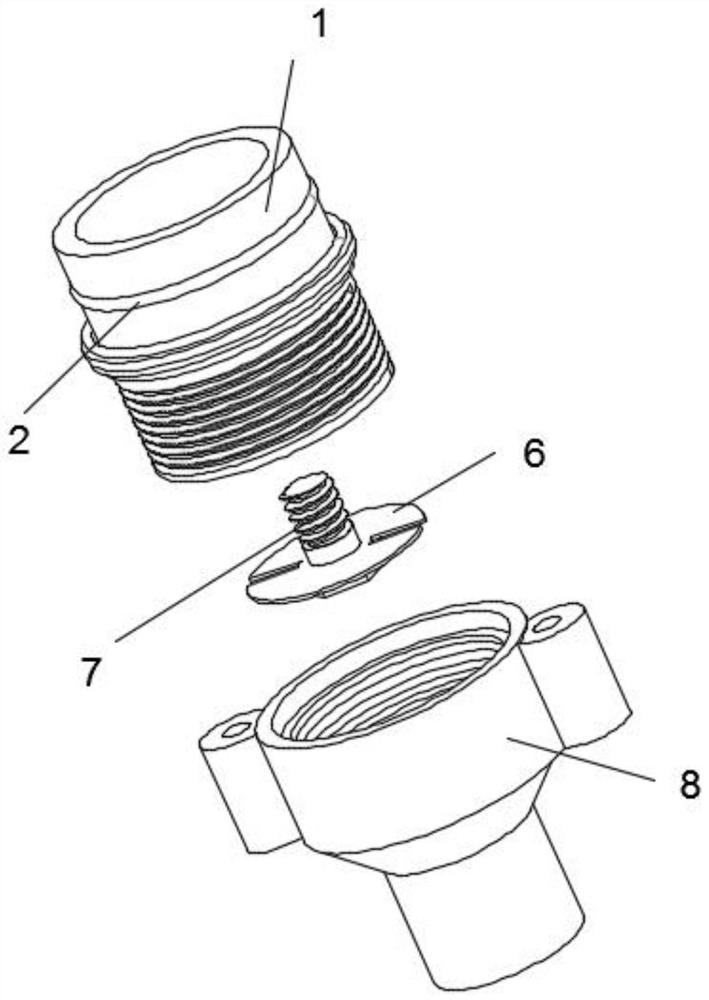

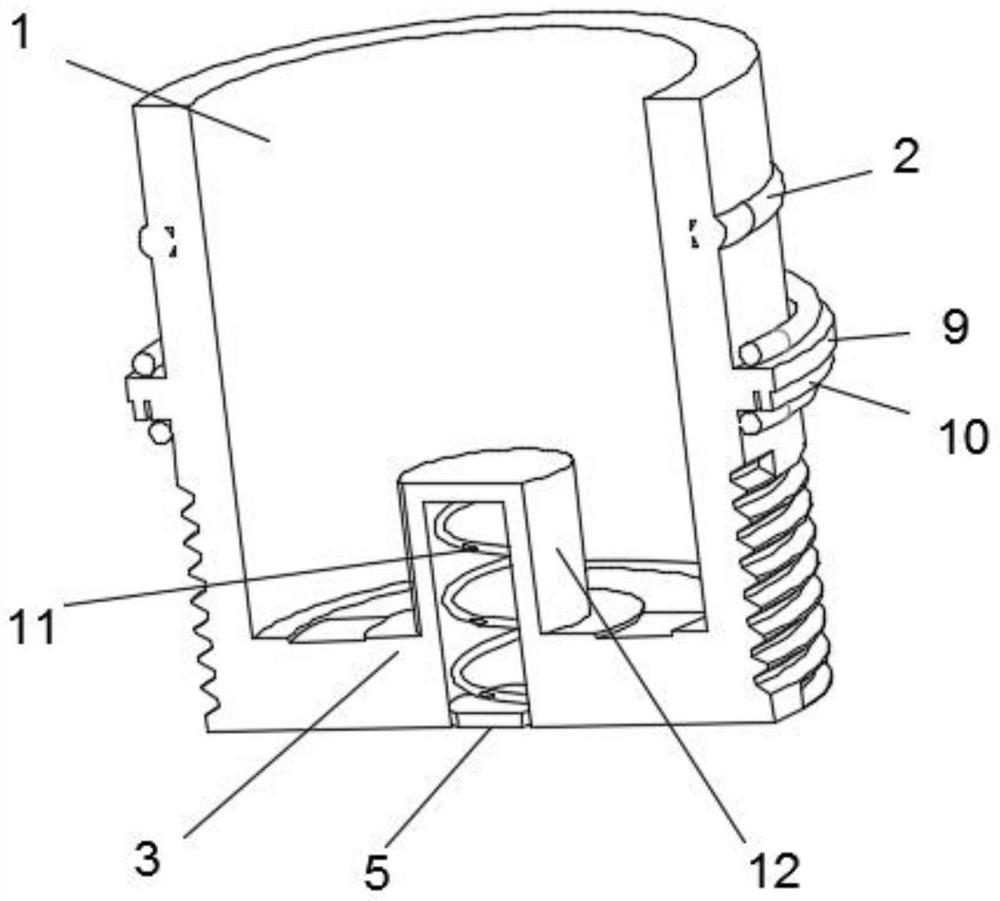

[0030] see Figure 1 to Figure 3 , the application provides a check valve, which is applied to a new type of fuel cell stack, including: a valve cover 1, a limit ring 9 is installed on the outside of the valve cover 1, and a plurality of sets of sealing rings 2 are sleeved on the outside of the valve cover 1, Gasket 10 is installed on the bottom of limit ring 9, and seal ring 2 is installed on the top and bottom of limit ring 9, and limit ring 9 tops on the top of valve body 8, and multiple groups of seal rings 2 play sealing effect, limit The gasket 10 at the bottom of the bit ring 9 acts as a seal;

[0031] The non-return part, the non-return part includes a fixed ring 3, the fixed ring 3 is installed on the bottom of the bonnet 1, the bottom of the bonnet 1 is provided with an arc-shaped channel 4, and the top of the fixed ring 3 is equipped with a fixed column 12, and the arc-shaped channel The groove 4 is opened at the bottom of the valve cover 1, which is in the shape o...

Embodiment 2

[0038] On the basis of Embodiment 1, in order to fix the connecting rod 7, the bottom of the fixed ring 3 is equipped with a baffle plate 5, and the top of the fixed ring 3 is equipped with a fixed column 12, and the inside of the fixed column 12 is provided with threads, and the fixed column 12 is equipped with a spring 11 inside, one end of the spring 11 is connected to the inner wall of the fixed column 12, the other end of the spring 11 is connected to the baffle plate 5, after the connecting rod 7 is set into the fixed column 12, under the push of the spring 11, Just make baffle plate 5 push away connecting rod 7, prevent connecting rod 7 from loosening.

Embodiment 3

[0040] On the basis of Example 2, in order to prevent the material from flowing back in the through groove 4, the bottom of the fixed ring 3 is provided with a connecting rod 7, and the outside of the connecting rod 7 is provided with a non-return plate 6. The non-return plate 6 is elastic. It can be bent and does not fit with the fixed ring 3. When the material normally flows out from the arc-shaped slot 4 from top to bottom, the check plate 6 will be bent. When the material flows back, the check plate 6 will stick to it. Secure the surface of ring 3 to prevent backflow.

[0041] Set the connecting rod 7 into the fixed column 12, the connecting rod 7 pushes the baffle plate 5 into the fixed column 12, the spring 11 is compressed, the connecting rod 7 fixes the non-return plate 6 on the bottom of the fixed ring 3, and the non-return plate 6 Cover the arc-shaped through groove 4, set the bottom of the valve cover 1 in the valve body 8, the limit ring 9 is on the top of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com