Sliding block guide track structure of four-column hydraulic press

A technology for hydraulic presses and guide rails, which is applied to presses, manufacturing tools, etc., can solve the problems of affecting the service life of the slider guide mechanism, time-consuming and laborious maintenance and replacement processes, affecting work efficiency, etc., so as to improve the strength and anti-eccentric load performance. It is convenient to adjust the clearance of the guide rail, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

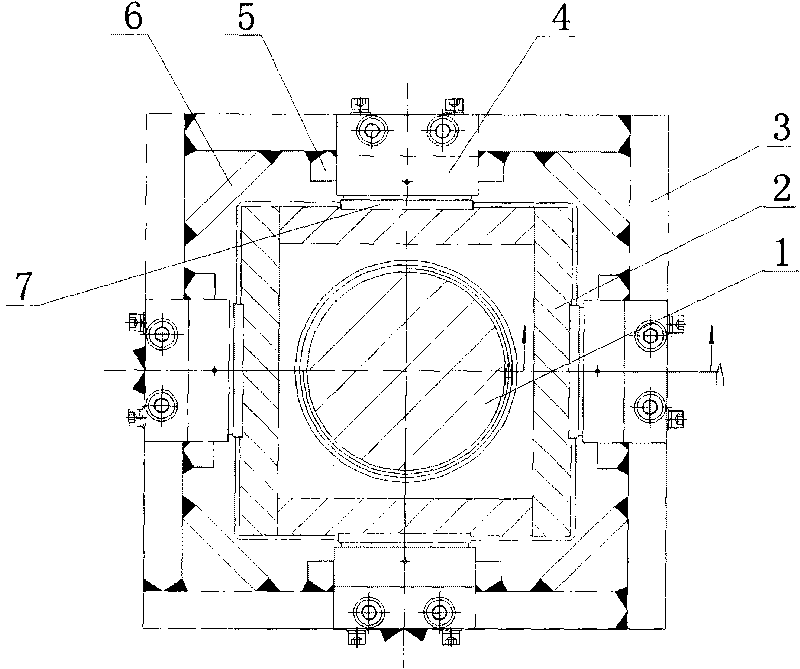

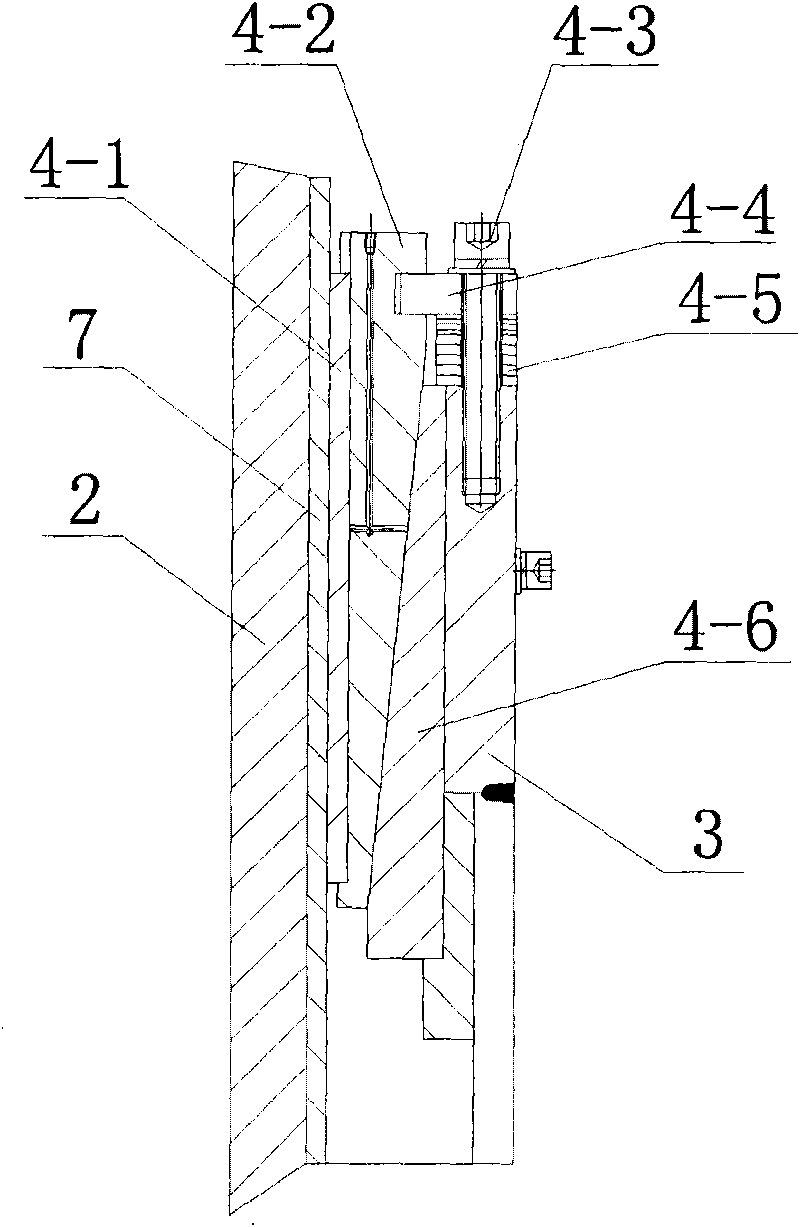

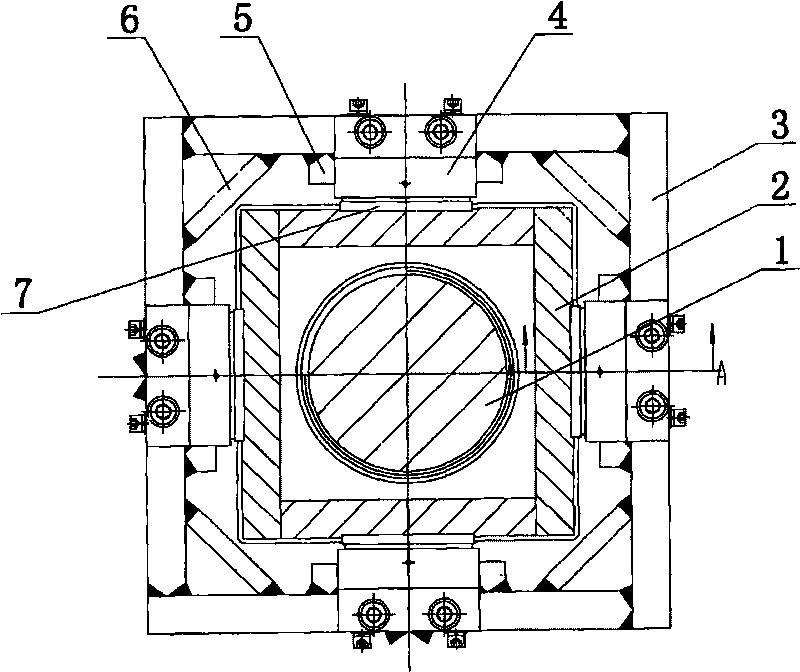

[0015] Such as figure 1 , figure 2 As shown, the four pillars 2 of the hydraulic press are rectangular, and the tie rods 1 connecting the upper beam and the lower beam of the hydraulic press are installed in the center holes of each pillar. Guide rails 7 are installed on the four sides of each pillar, and the four corners of the sliders of the hydraulic press are all A rectangular guide cavity 3 matching the guide rail of the pillar is made. The guide cavity is welded by four steel plates, and 45° reinforcement ribs 6 are welded at the four inner corners of the guide cavity. The inside of the guide cavity is correspondingly installed with a guide plate matched with the guide rail. 4-1 and its adjustment device 4. The adjustment device is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com