Sliding lead-core shock absorption and insulation rubber support for bridge

A technology of lead-core rubber bearings and lead-core rubber, which is applied in bridges, bridge parts, bridge construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

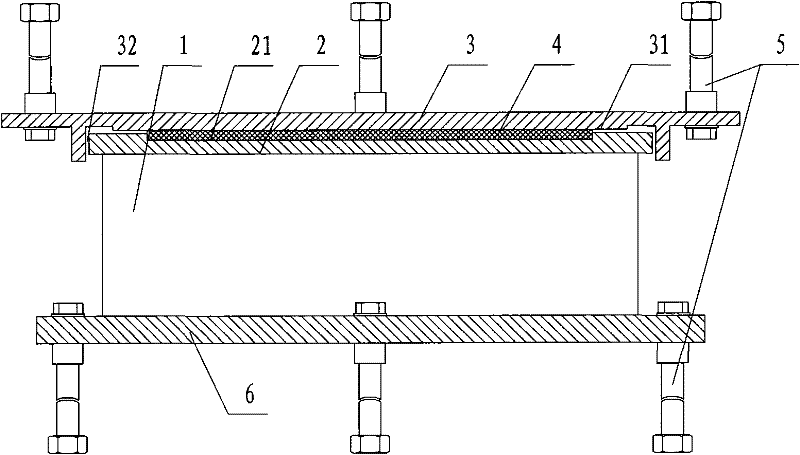

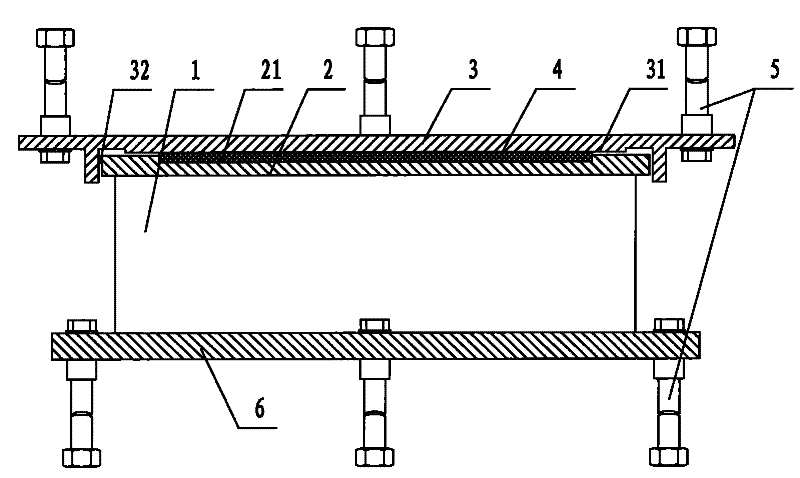

[0024] In this embodiment, the two ends of the sliding plate 3 along the transverse direction of the bridge are respectively provided with transverse stoppers downwards to form a sliding groove 32, and the upper connecting plate 2 and the sliding plate 4 are located in the sliding grooves to slide and cooperate with them; The sliding plate 3 slides laterally relative to the sliding plate 4 to adapt to the large longitudinal deformation of the bridge due to the influence of the environment in practice, which is conducive to ensuring the stability of the bridge; the horizontal stop is formed by bending downwards at both ends of the sliding plate 3, Easy and convenient to make.

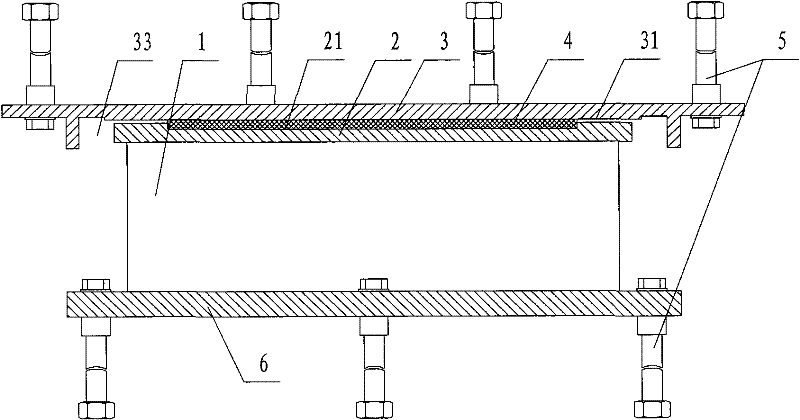

[0025] In this embodiment, the two ends of the sliding plate 3 along the longitudinal direction of the bridge are respectively provided with longitudinal stoppers downwards, and the two longitudinal stoppers and the two longitudinal ends of the upper connecting plate 2 are provided with a sliding distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com