soft start valve

A soft start, valve stem technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of common parts that cannot be reduced, increase the cost of parts manufacturing and inventory, and increase the number of parts, so as to reduce the manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

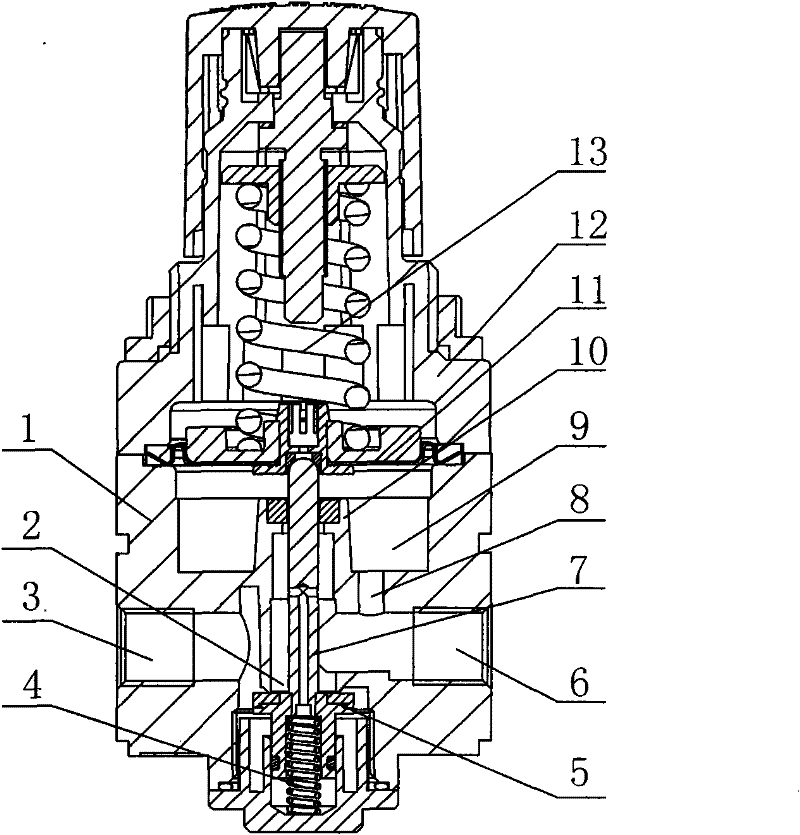

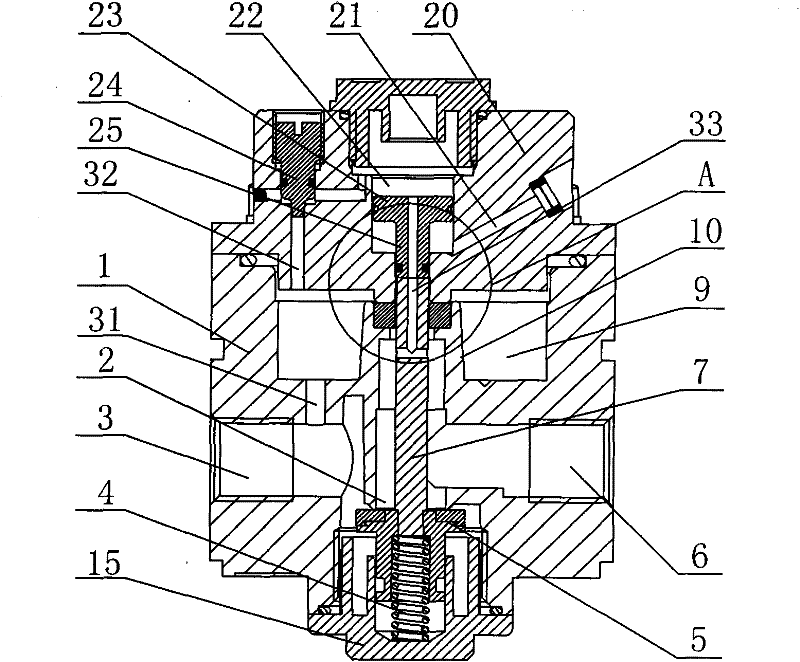

[0016] Such as figure 2 As shown, the soft start valve of the present invention has a valve body 1, the valve body 1 is provided with an inlet 3 and an outlet 6 for the fluid to enter and exit, the valve body 1 is provided with a valve port 2 between the inlet 3 and the outlet 6, and the valve core 5 and The valve port 2 is opposite and can close the valve port 2. The top of the valve core 5 is connected with the valve stem 7. The valve stem 7 can slide up and down in a valve stem guide sleeve 10 in the center of the valve body. The bottom of the valve core 5 is connected to the valve core. The springs 4 are connected, and the other end of the spool spring 4 bears on the lower end cover 15 . The spool spring 4 presses the spool 5 on the valve port 2 to close the valve port 2.

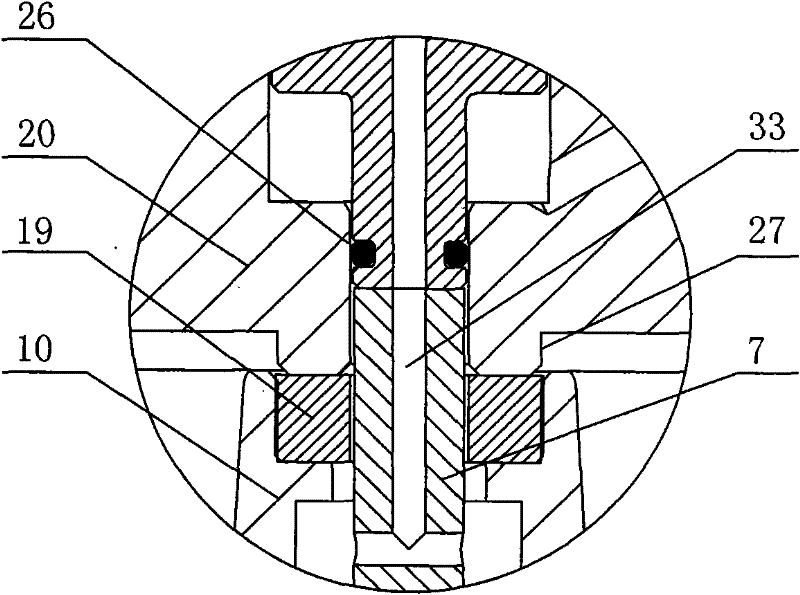

[0017] The valve body 1 is also provided with a chamber 9 surrounding the valve stem guide sleeve 10, and the top of the valve body 1 is provided with a valve cover 20, which closes the chamber 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com