Energy-saving tri-dimensional screen

A stencil, three-dimensional technology, applied in the direction of sheets/boards, building elements, etc., to increase stiffness and strength, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

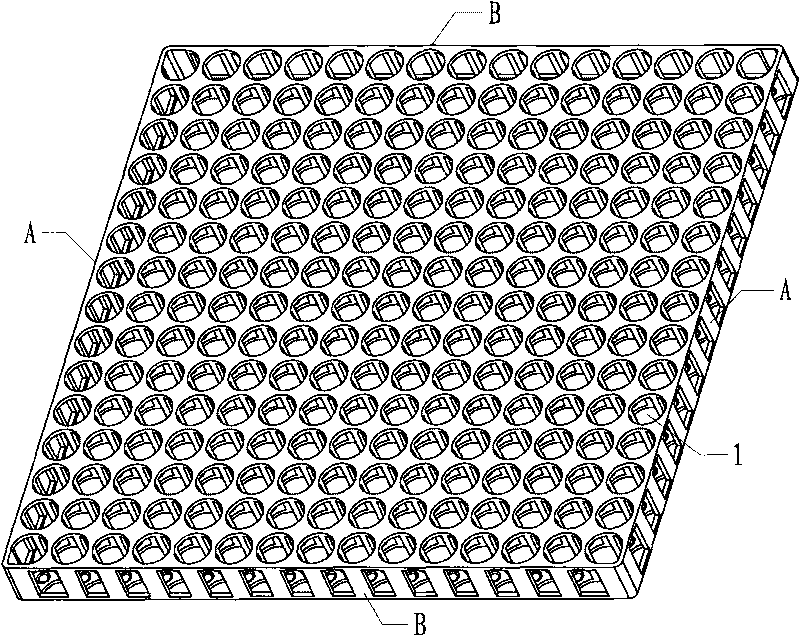

[0019] Such as figure 1 As shown, this product is molded with a mold at one time. After one molding, the upper and lower ribs are flat. The thickness requirements can be customized according to actual requirements. The center is the fulcrum of the ribs to support the upper and lower ribs. The diameters of the holes on the front and back sides can be customized according to the requirements of actual conditions. Surface A is a splicing surface, and there is a central boss on the side rib of A surface. The side of side B is a middle hole. The energy-saving three-dimensional screen can be positioned and assembled according to actual needs, and combined into a larger area for use.

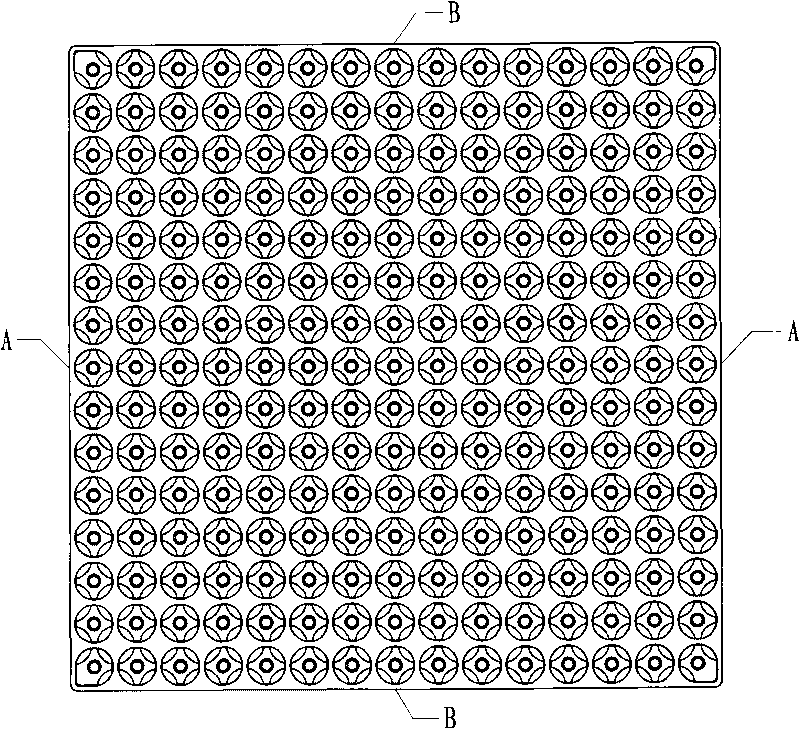

[0020] figure 2 The middle diameter of the energy-saving three-dimensional stencil shown is arranged equidistantly, and the depth is the total thickness of the energy-saving three-dimensional stencil minus the wall thickness of the reverse side (about 2.5 mm). Depends on requirements. The larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com