High-precision aerosol can pressure resistance tester

A pressure tester, aerosol can technology, applied in the direction of using stable tension/pressure to test material strength, using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of affecting test efficiency and test accuracy, degree of automation Low, test liquid leakage and other problems, to achieve the effect of good sealing, high degree of automation, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

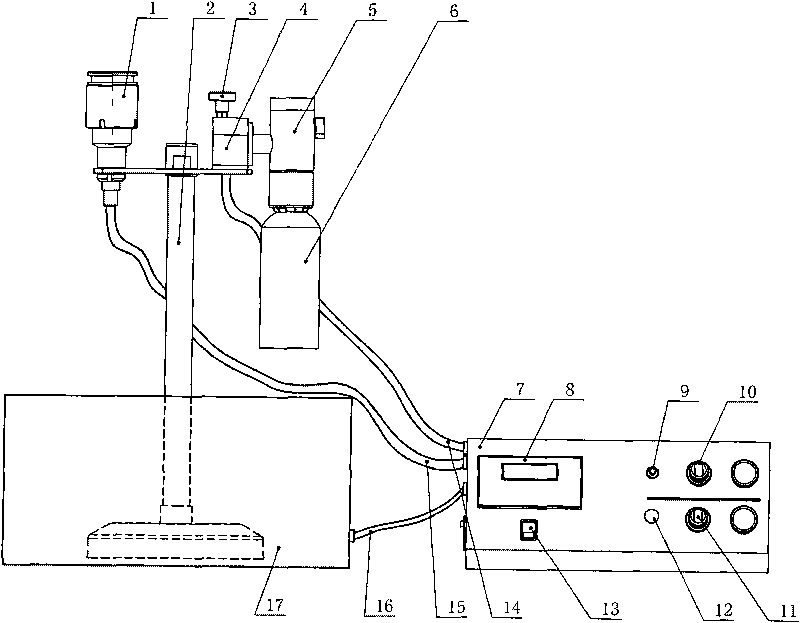

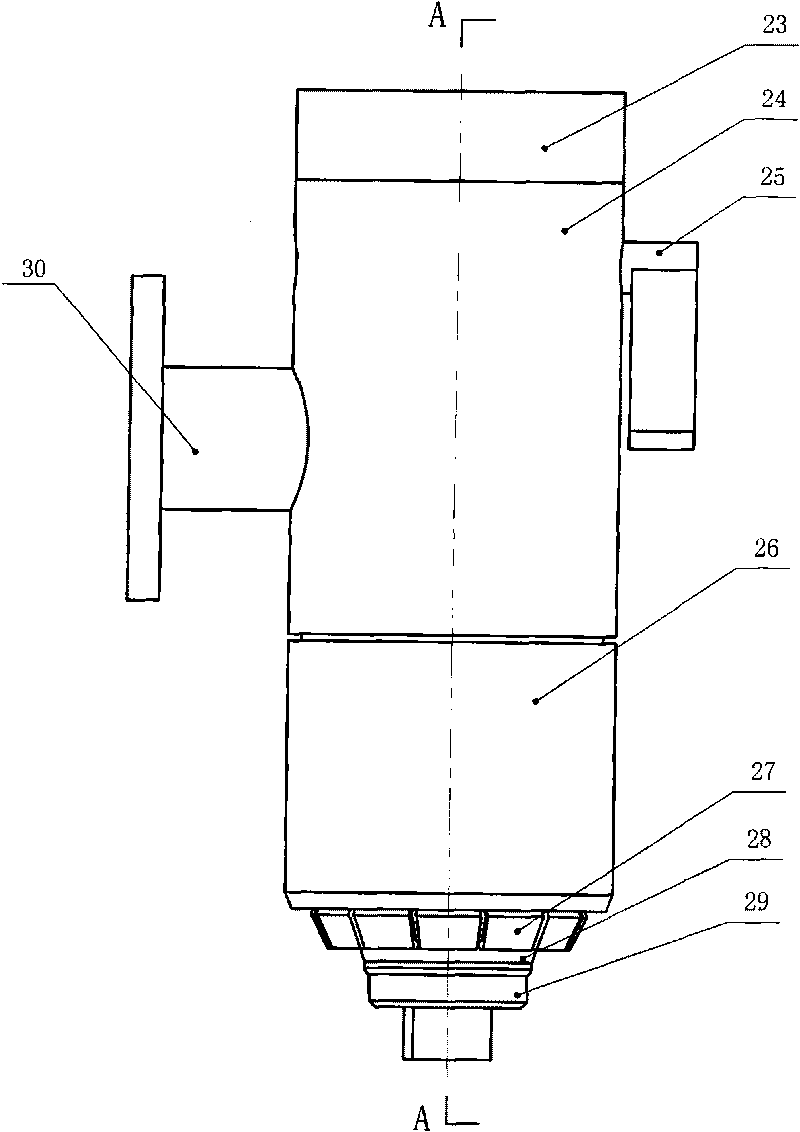

[0031] A high-precision aerosol can pressure tester is composed of a control box 7, a tank body test head 5, a valve cover test head 1, and a test frame 2, and the tank body test head and the valve cover test head are fixed on the test frame.

[0032] The innovations of this high-precision aerosol can pressure tester are:

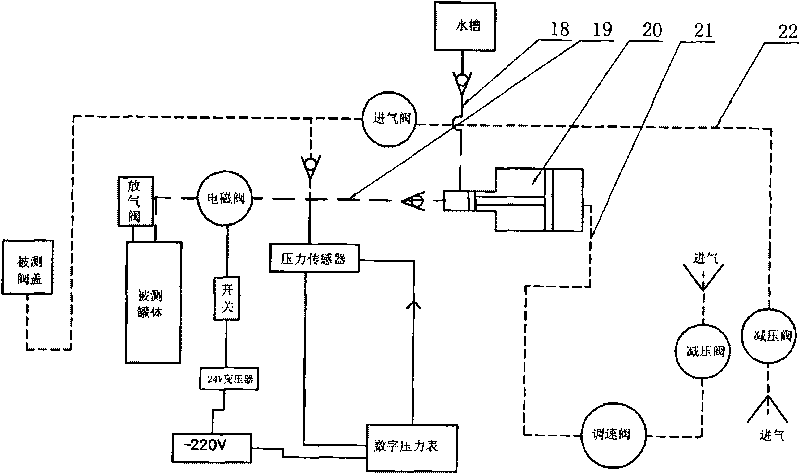

[0033] The tank body test head and the valve cover test head are connected to the water outlet and the gas outlet of the control box through the outer liquid pipeline 14 and the outer gas pipeline 15 respectively. The tank test head is fixed on the test frame through a mounting seat 4, and an air release valve 3 is arranged on the mounting seat. A valve cover test passage and a tank bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com