Connection method and connection structure of regulating transformer and power transformer

A technology for voltage regulating transformers and power transformers, applied in the field of transformers, can solve the problems of large amount of transformation of transformer shells, affecting the stability of transformers, and large amount of transformation projects, achieving good promotion and use value, simple structure, and saving construction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

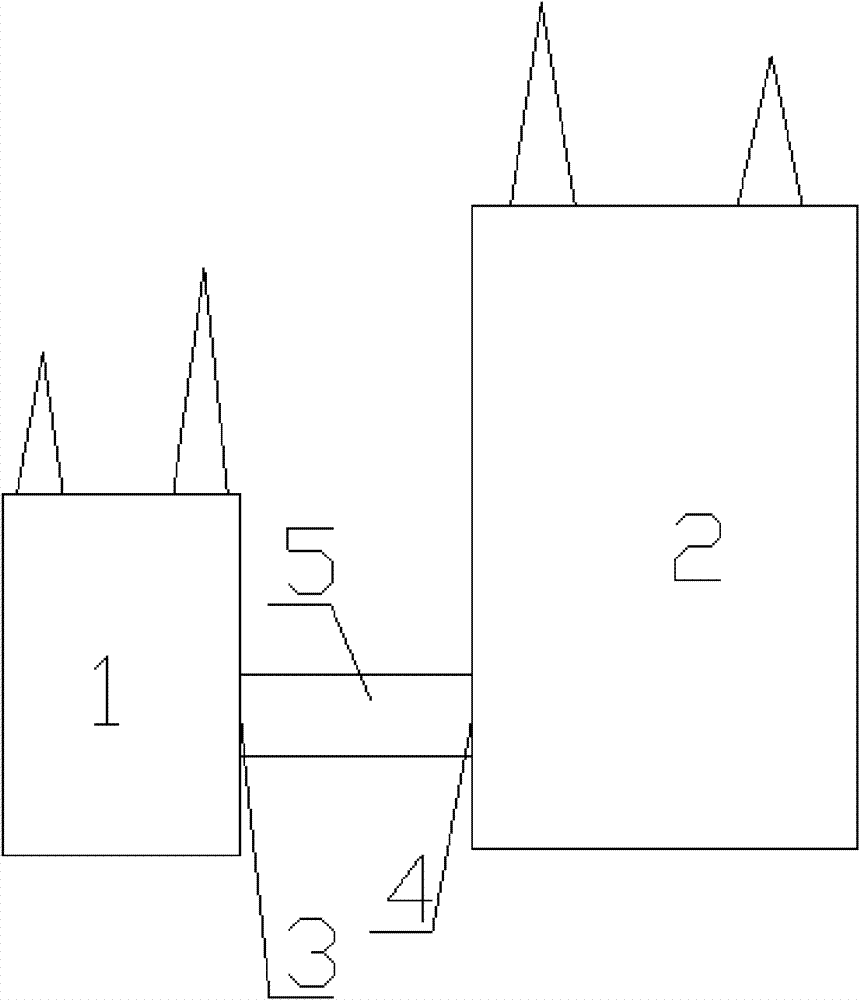

[0011] Example: as figure 1 As shown, a high-voltage terminal connection hole 3 is opened on the side of the voltage regulating transformer 1, and a secondary coil connection hole 4 is opened on the side of the power transformer 2. The high-voltage terminal connection hole 3 is opposite to the secondary coil connection hole 4. A wire 5 is connected to the high-voltage side coil of the transformer 1, and the wire 5 is connected to the secondary coil in the power transformer 2 after passing through the high-voltage terminal connection hole 3 and the secondary coil connection hole 4. The wire 5 is a three-phase wire, and the used The conductor 5 is an oil-filled busbar, an inflatable busbar or a cable. In this example, an oil-filled busbar filled with transformer oil is preferred. At the same time, a flexible segment conductor is provided on the conductor 5, so that when the foundation on which the transformer is placed changes, the flexible segment conductor can be used for the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com