Three-station combinational machine

A combined machine and three-station technology, which is applied in the direction of forming tools, positioning devices, manufacturing tools, etc., can solve the problems of difficult control of product quality and standardization, high defective rate and labor intensity, and insufficient security of employees. Achieve the effects of easy product quality assurance, low scrap rate, and reduced labor costs and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

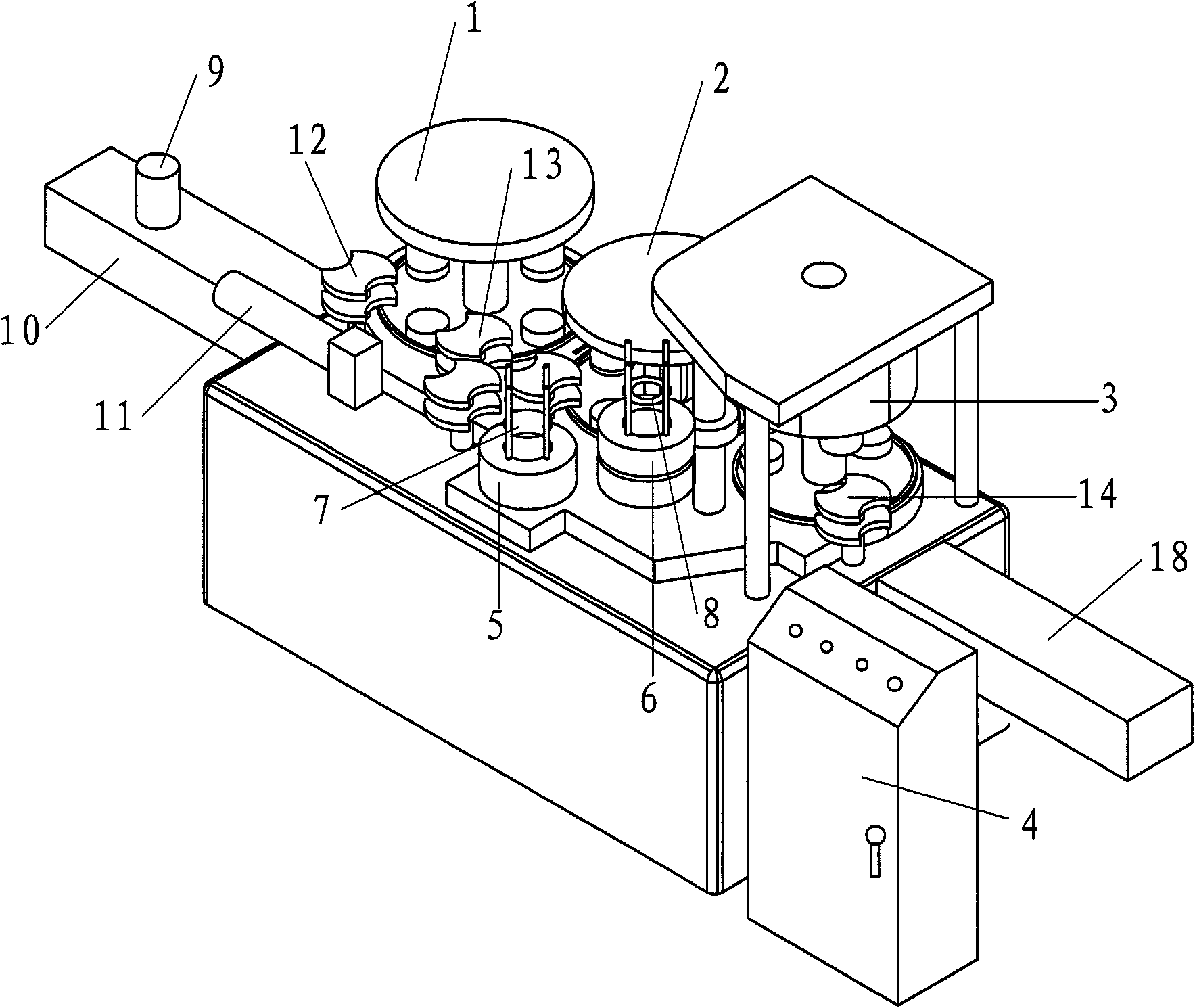

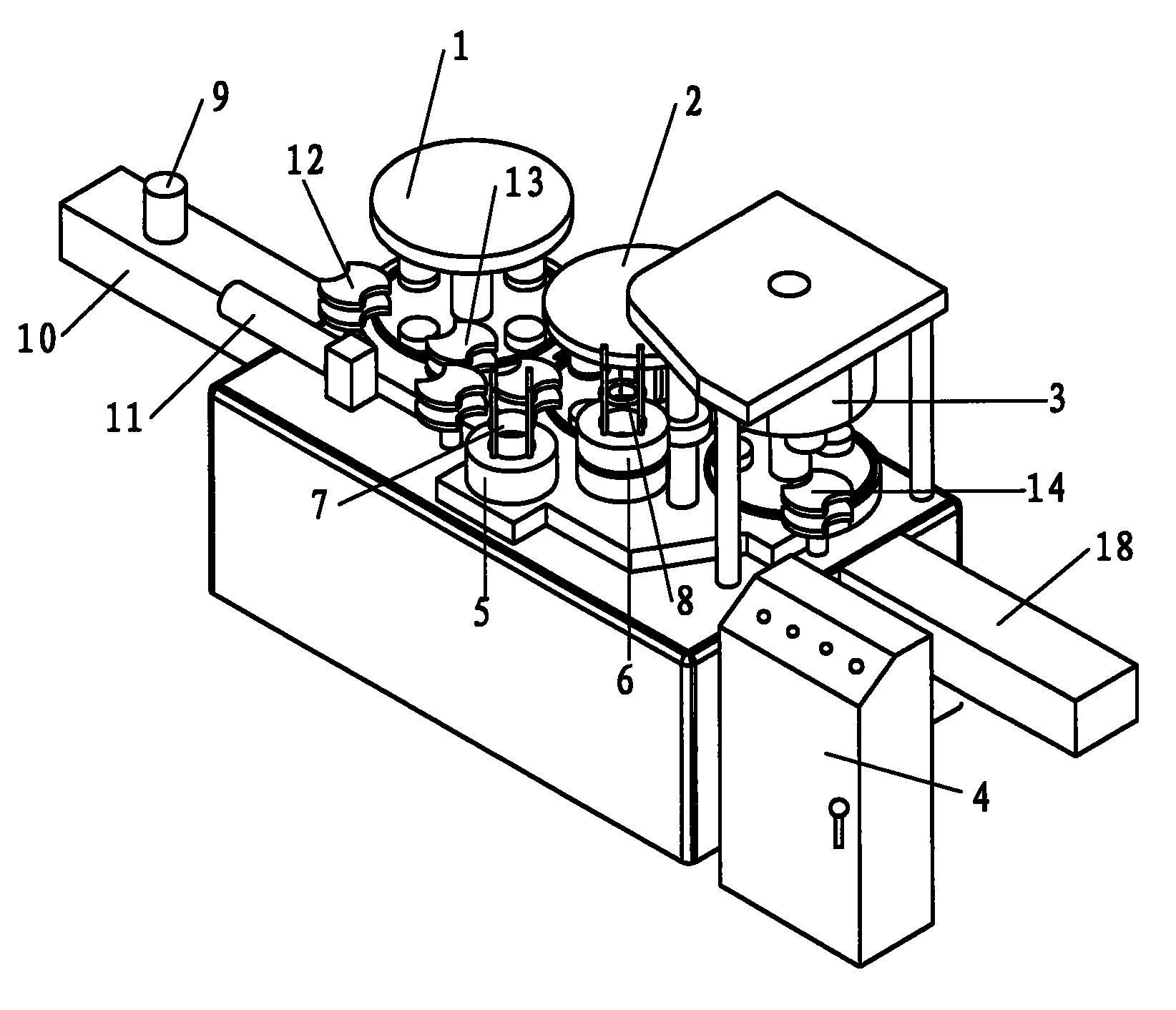

[0009] The three-station combination machine of the present invention will be further elaborated below in conjunction with the accompanying drawings:

[0010] as attached figure 1 Shown, a kind of three-station combined machine, it comprises the flanging tool mold 1 that carries out flanging to the can body of the jar, the bottom sealing tool mold 2 that connects the tank bottom and the tank body, and the tank cover and the can body are carried out The sealing tool 3 for connection processing, the automatic bottoming device 5 for the storage tank bottom, the automatic cap dropping device 6 for the storage tank cover, the input conveyor belt 10 located in front of the flanging tool 1, and the output conveyor located behind the sealing tool 3 Belt 18 and PLC electrical control cabinet 4. The three-station combination machine also includes a screw conveying device 11, which provides power for the semi-finished can body 9 in the conveying link.

[0011] The flanging tooling 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com