Micro-bit and processing apparatus using the micro-bit

A technology of micro-drills and tools, applied in the field of processing tools and carbide micro-drills, can solve the problems of high friction between the drill tip and the PCB board, broken drills, and reduced drill size, etc. The effect of broken drill and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

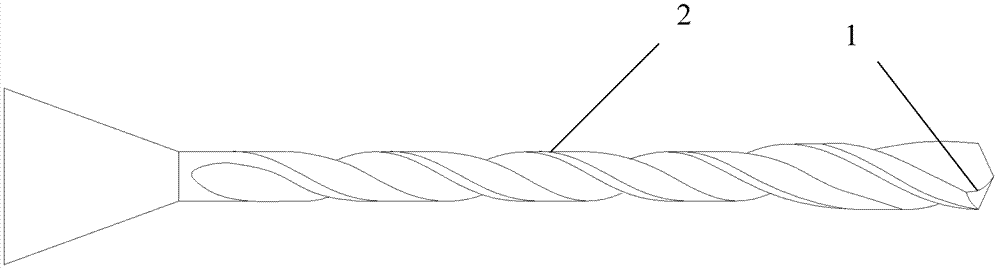

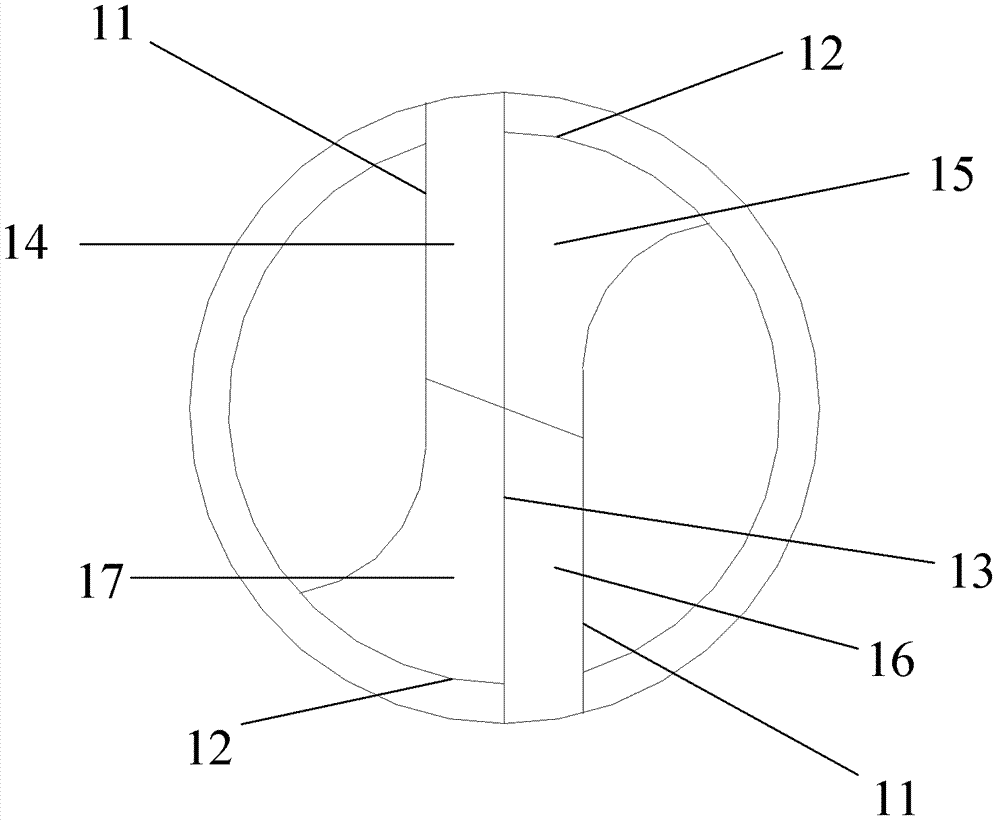

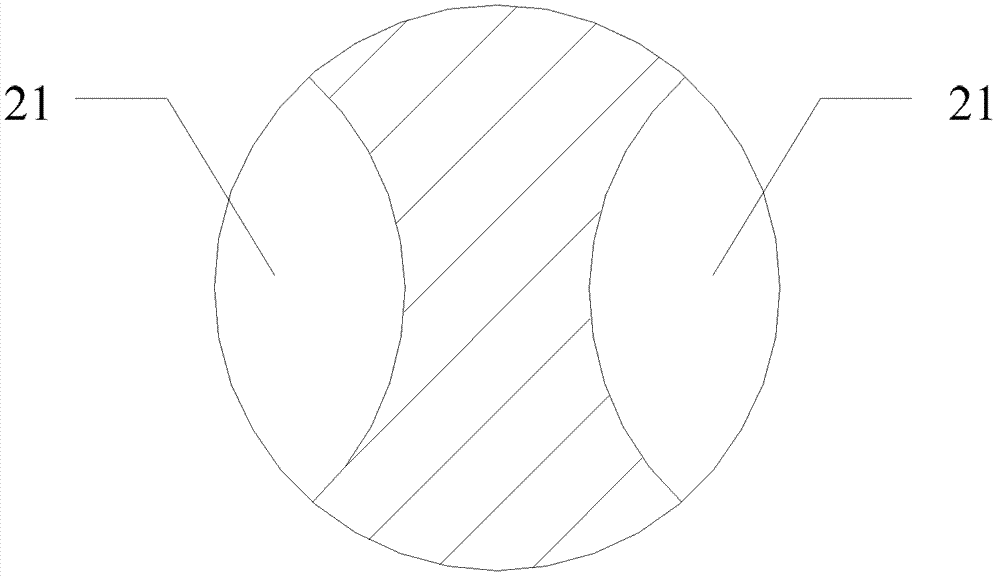

[0026] The structure of the first embodiment of the micro drill bit of the present invention is as Figure 4-6 As shown, the shown micro drill includes a drill tip and a drill body, and the drill tip includes a main cutting edge 31, two auxiliary cutting edges, and three minor cutting edges 32; the auxiliary cutting edge includes a first The auxiliary cutting edge 301 and the second auxiliary cutting edge 302; between the first auxiliary cutting edge 301 and the first and second flanks of the drill tip, and between the third flank 16 and the fourth flank 17 The intersection line 33 that forms between intersects, and makes the length of intersection line 33 less than the length of micro-drill diameter; Described minor cutting edge 32 is connected with main cutting edge 31 and two auxiliary cutting edges respectively; Wherein, described main cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com