Mine tailing sand brick and preparation method thereof

A technology of tailings sand and sand bricks, which is applied in the field of building bricks, can solve the problems of high production cost and large proportion, and achieve the effects of low cost, simple production process, and high utilization rate of tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

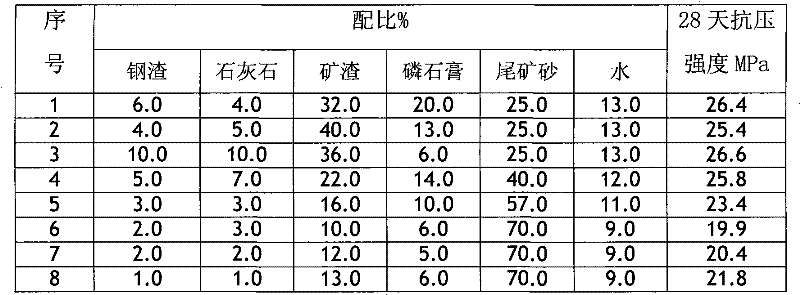

[0022] A tailings sand brick is prepared from steel slag, limestone, slag, phosphogypsum, tailings sand and water raw materials. The weight percentage of each raw material is shown in Table 1.

[0023] Table 1: the compressive strength of each raw material proportioning and product (the proportioning in the table is percentage by weight):

[0024]

[0025] The tailings sand is made of phosphorus tailings sand (phosphate rock tailings sand), and the particle size of the phosphorus tailings sand is less than 2mm.

[0026] The results of the 28-day compressive strength of tailings sand bricks are shown in Table 1, and other properties of the product (tailings sand bricks) can also meet the requirements of the JC / T422-2007 "non-sintered waste tailings bricks" standard.

[0027] The preparation method of above-mentioned a kind of tailings sand brick, it comprises the steps:

[0028] 1) Ingredients: select steel slag, limestone, phosphogypsum, slag, tailings sand and water raw m...

Embodiment 2

[0034] A kind of tailings sand brick, which is prepared from steel slag, limestone, slag, phosphogypsum, tailings sand and water raw materials, and the weight percentage is formulated according to the eighth formula (serial number 8) in Example 1, see Table 1 .

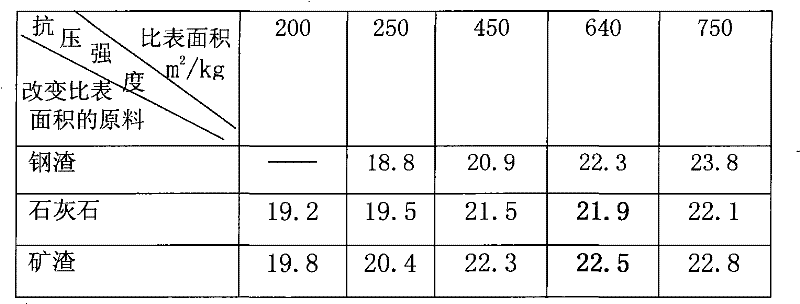

[0035] The preparation method is basically the same as in Example 1, and the difference from Example 1 is: the specific surface area of a kind of raw material in steel slag, limestone, and slag raw materials is changed successively in Example 1, and the specific surface area of the remaining two raw materials is kept the same as in Example 1. The specific surface area of raw material changes and the 28-day compressive strength of tailings sand bricks are shown in Table 2. Other properties of the product can also meet the requirements of the JC / T422-2007 "Non-sintered waste tailings bricks" standard.

[0036] Table 2: Comparison of compressive strength of products with different specific surface areas by grinding...

Embodiment 3

[0039]A kind of tailings sand brick, which is prepared from steel slag, limestone, slag, phosphogypsum, tailings sand and water raw materials, and the weight percentage is formulated according to the eighth formula (serial number 8) in Example 1, see Table 1 .

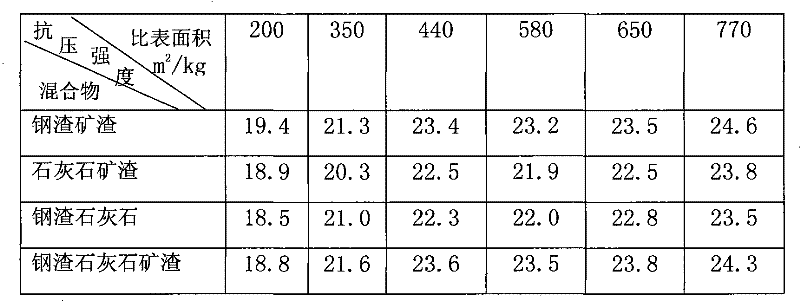

[0040] The preparation method is basically the same as that of Example 1, except that it is different from Example 1 in that: steel slag, limestone, and any two or more (including any two) of slag are mixed and ground, and the composition, specific surface area, and 28% of the tailings sand brick of each mixture are mixed and ground. The results of compressive strength per day are shown in Table 3, and other properties of the product can also meet the requirements of the JC / T 422-2007 "Non-sintered Garbage Tailings Brick" standard.

[0041] Table 3: Comparison of compressive strength of products mixed and ground with some raw materials (unit: MPa)

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com