Degreasing phosphate-free laundry detergent powder

A technology for washing powder and degreasing, which is applied in the direction of inorganic non-surface-active cleaning compositions, etc., and can solve the problems of insignificant actual effect and inability to wash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh raw materials (grams) according to the following weights:

[0022] Mother powder 63; AES 12; edible sodium carbonate 18; potassium sulfate 3; edible sodium bicarbonate 2.8; active protease 1; essence 0.2.

[0023] The mother powder is a mixture of: sodium silicate 5.67; sodium sulfate 37.8; benzenesulfonic acid 10.08; sodium carbonate 9.45.

[0024] Preparation:

[0025] First, mix AES, edible sodium carbonate, edible sodium bicarbonate, and potassium sulfate in proportion, and stir evenly; then mix active protease and flavor evenly in proportion; finally, mix these two mixtures with mother powder evenly, and the test is up to standard Then put it in the packaging bag.

Embodiment 2

[0027] Weigh raw materials (grams) according to the following weights:

[0028] Mother powder 61; AES11.5; edible sodium carbonate 20; potassium sulfate 4; edible sodium bicarbonate 3; active protease 0.5.

[0029] The preparation method is as in Example 1.

[0030] The mother powder is: a mixture of sodium silicate 4.88; sodium sulfate 39.65; benzenesulfonic acid 6.1; sodium carbonate 10.37.

Embodiment 3

[0032] Weigh raw materials (grams) according to the following weights:

[0033] Mother powder 65; AES10 sodium carbonate 16.5; potassium sulfate 5; sodium bicarbonate 2; active protease 1.4; essence 0.1.

[0034] The mother powder is: a mixture of sodium silicate 6.5; sodium sulfate 37.05; benzenesulfonic acid 13; sodium carbonate 8.45.

[0035] The preparation method is as in Example 1.

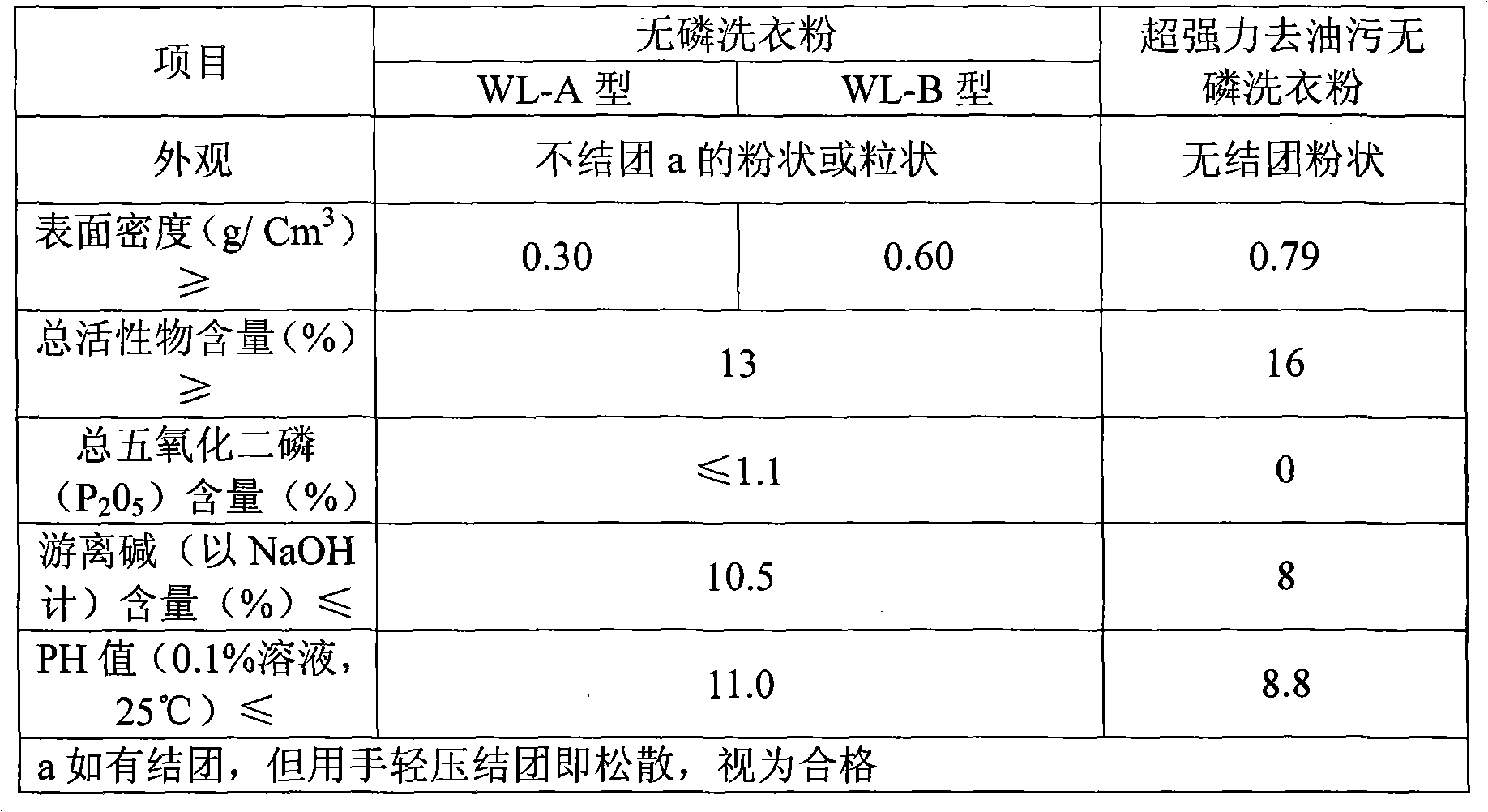

[0036] The following are the comparison of the degreasing ability experiment of the present invention and the physicochemical index of the present invention:

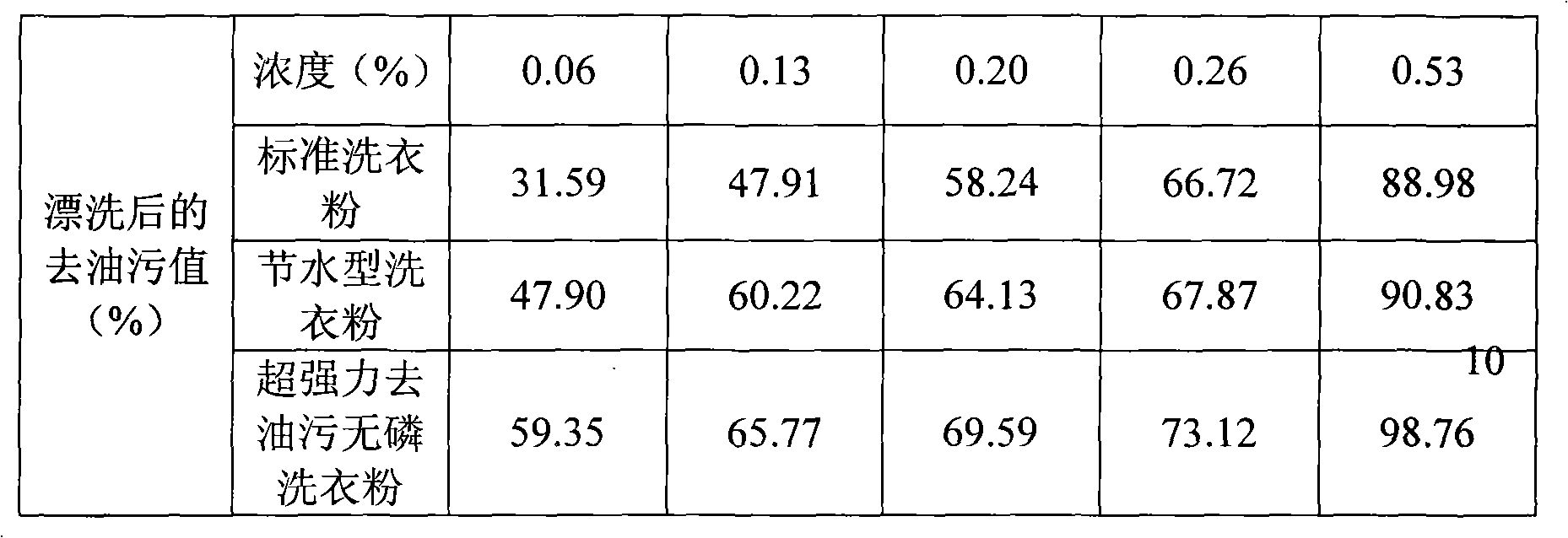

[0037] Table 1 compares the degreasing value of washing powder of the present invention with standard washing powder and water-saving type washing powder after rinsing:

[0038] Table 1 The degreasing value of three kinds of washing powders washed under different concentrations

[0039]

[0040] As can be seen from Table 1, the degreasing ability of the super-powerful degreasing non-phosphorus washing powder of the present inven...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap