High-tensile strength sponge and preparation method thereof

A high-strength, sponge technology, applied in the field of sponge and its preparation, to achieve the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

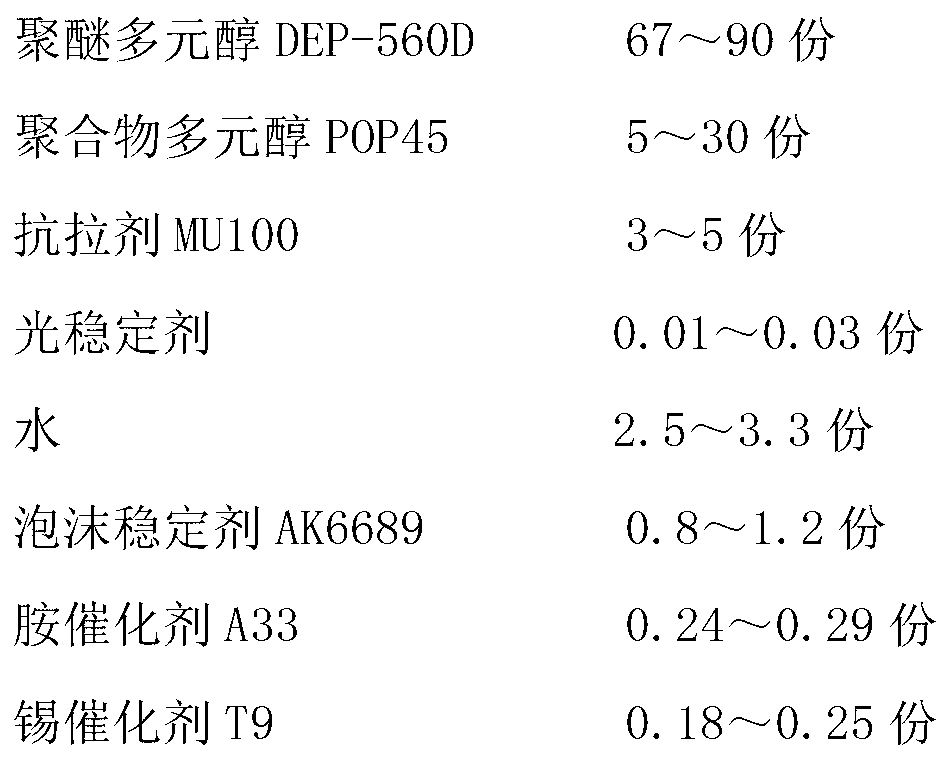

[0016] Sponge 1 is formulated with the following components and methods:

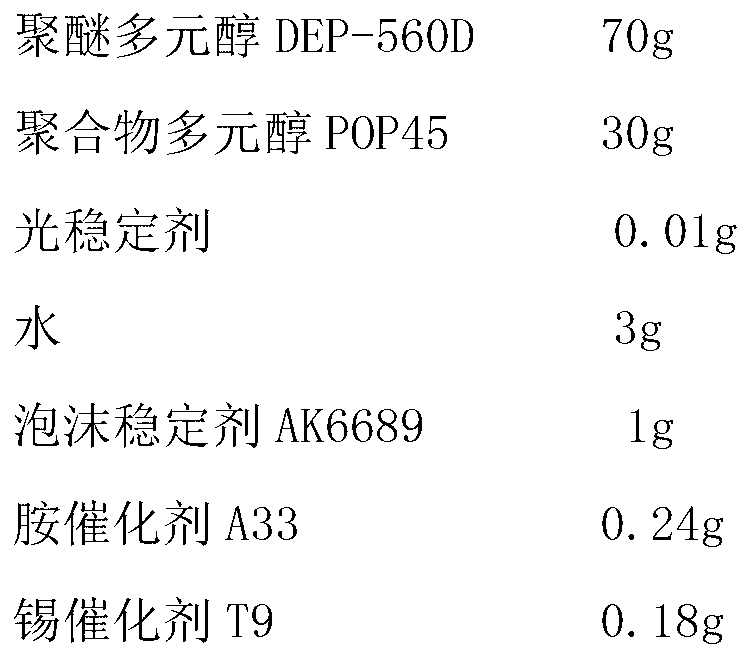

[0017] Component A:

[0018]

[0019] Component B:

[0020] Isocyanate 38g,

[0021] Add the raw materials of component A into the mixer in proportion and mix well, adjust the material temperature of component A to 25°C, adjust the speed of the agitator to 7000r / min, pour component B preheated to 25°C into A Stir for 8s, then pour into the pre-mould, observe the foaming situation, after starting, ripen for 24 hours, and then test the performance.

[0022] Sponge 2, formulated with the following components and methods:

[0023] Component A:

[0024]

[0025] Component B:

[0026] Isocyanate 38g,

[0027] Add the raw materials of component A into the mixer in proportion and mix well, adjust the material temperature of component A to 25°C, adjust the speed of the agitator to 7000r / min, pour component B preheated to 25°C into A Stir for 8s, then pour into the pre-mould, observe the foaming situ...

Embodiment 2

[0032] Sponge 3, formulated with the following components and methods:

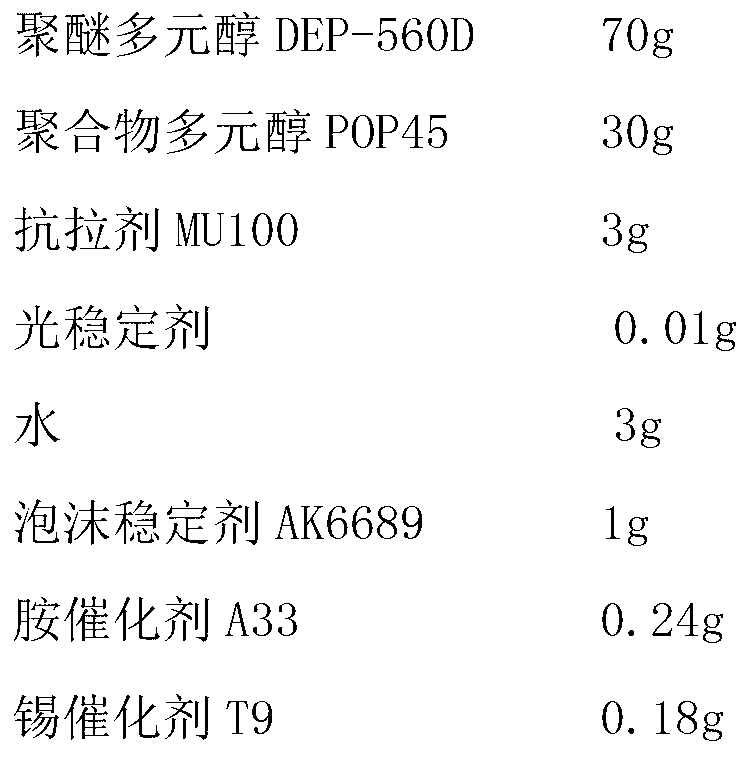

[0033] Component A:

[0034]

[0035] Component B:

[0036] Isocyanate 34g,

[0037] Add the raw materials of component A into the mixer in proportion and mix well, adjust the material temperature of component A to 23°C, adjust the speed of the agitator to 7000r / min, pour component B preheated to 23°C into A Stir for 8s, then pour into the pre-mould, observe the foaming situation, after starting, ripen for 24 hours, and then test the performance.

[0038] Sponge 4 is formulated with the following components and methods:

[0039] Component A:

[0040]

[0041]

[0042] Component B:

[0043] Isocyanate 34g,

[0044] Add the raw materials of component A into the mixer in proportion and mix well, adjust the material temperature of component A to 23°C, adjust the speed of the agitator to 7000r / min, pour component B preheated to 23°C into A Stir for 8s, then pour into the pre-mould, observe the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com