Method for efficiently cultivating lactobacillus and producing lactic acid

A technology of lactic acid bacteria and lactic acid, applied in the biological field, to achieve high-efficiency cultivation and high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Selection of lactic acid bacteria strains and fermentation medium

[0016] The strain used in the experiment of the present invention is a strain of lactic acid bacteria USTB-08 (Lactobacillus sp.USTB-08) screened by ourselves. The composition of the lactic acid bacteria culture medium is as follows: protein age 10.0g, beef extract 10.0g, yeast extract 5.0g, diammonium citrate 2.0g, sodium acetate 5.0g, glucose 20.0g, MgSO 4 ·7H 2 O 0.58g, MnSO 4 4H 2 O 0.25g, Tween 80 1.0ml, 1000ml deionized water.

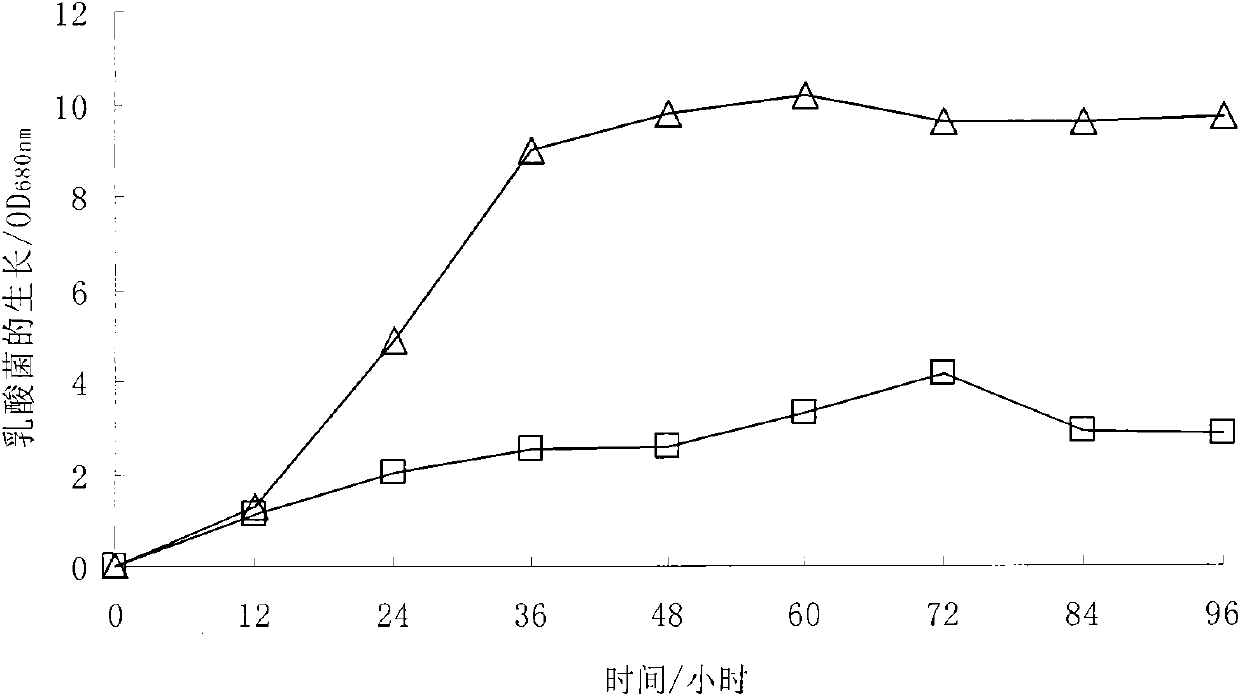

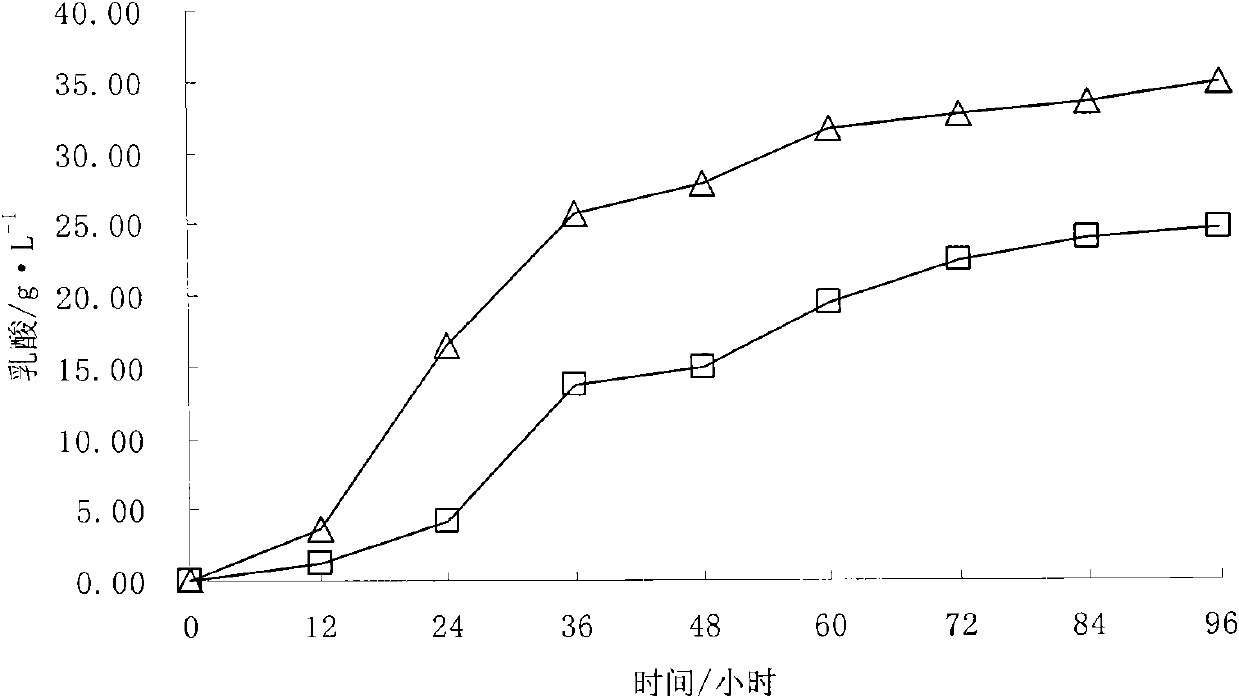

[0017] 2. Fed-batch fermentation culture of lactic acid bacteria

[0018] Use a 50-liter fully automatic fermenter, add 30 liters of liquid medium, sterilize at 121°C for 20 minutes and cool to 35°C, inoculate 300ml of lactic acid bacteria cultured in batches as strains, stir at 200 rpm and temperature 35°C Cultivate anaerobically at ℃. A pH probe is inserted in the culture for online automatic feed-in feeding solution to keep the pH constant at 7.0, and the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com