Method for increasing fermentation yield of plasmids

A plasmid and yield technology, applied in the field of microbial fermentation, can solve problems such as the inability to realize industrial scale production, the inability to guarantee the quantity and quality of plasmids, and the quality of plasmid DNA is not good enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

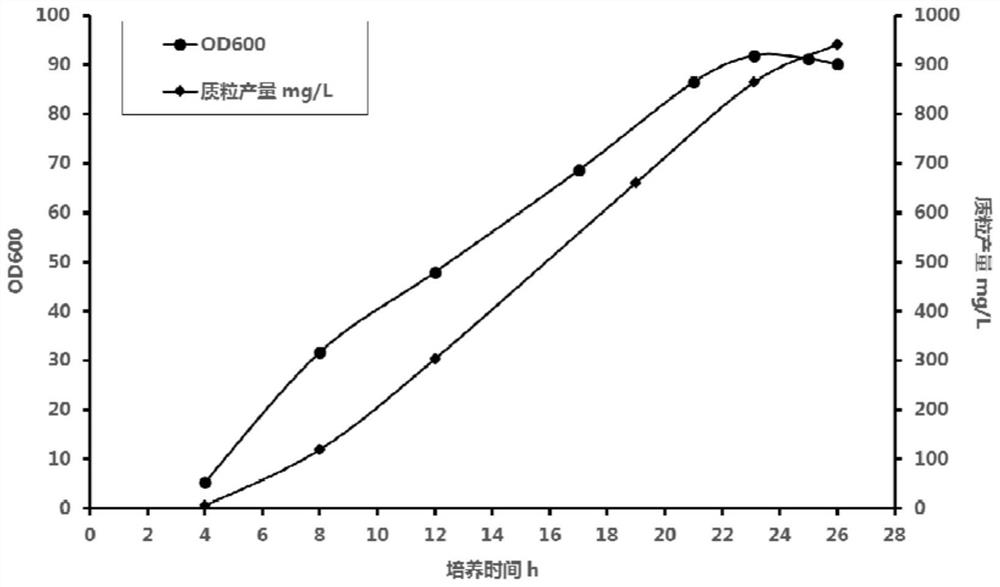

Embodiment 1

[0035] Embodiment 1, the method for improving plasmid fermentation yield

[0036] The present embodiment provides a kind of method for improving plasmid fermentation yield, it comprises the following steps:

[0037] Step 1. Fermentation preparation

[0038] Using a glass fermenter, first calibrate the pH electrode, and install the newly calibrated pH electrode and dissolved oxygen electrode to the corresponding positions; then, install the exhaust and condensate pipes, acid bottles, lye bottles, defoamer bottles, The feed bottles and pipelines of feed medium A and feed medium B were installed in the corresponding positions of the fermenter, and sterilized at 121°C for 40 minutes.

[0039] Step 2. Fermentation tank parameter setting

[0040] Pour 1.2L of the prepared initial culture medium into the fermenter, sterilize at 121°C for 30 minutes. After the fermenter is cooled, transfer the rest of the feed into the corresponding feed bottle in a sterile environment, and then co...

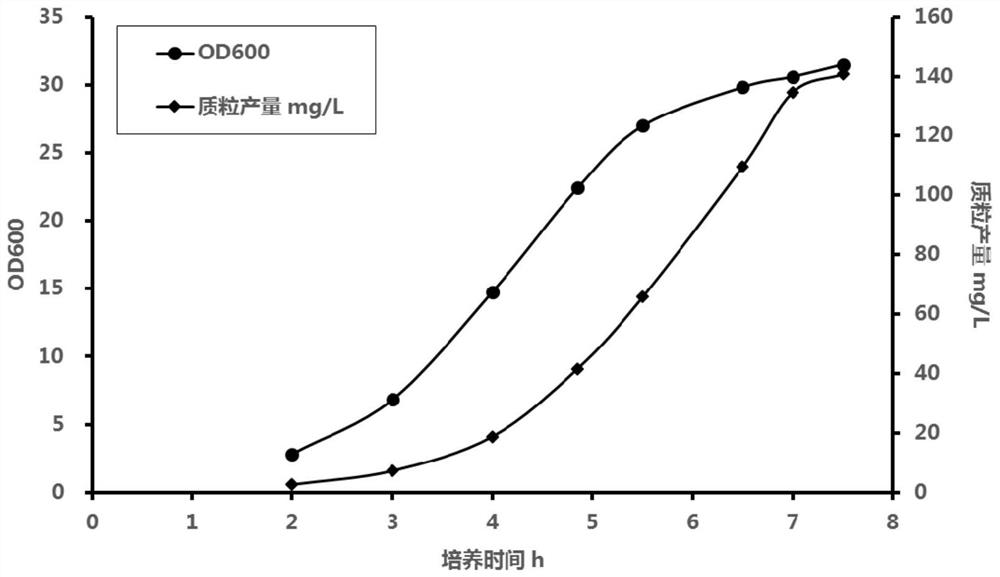

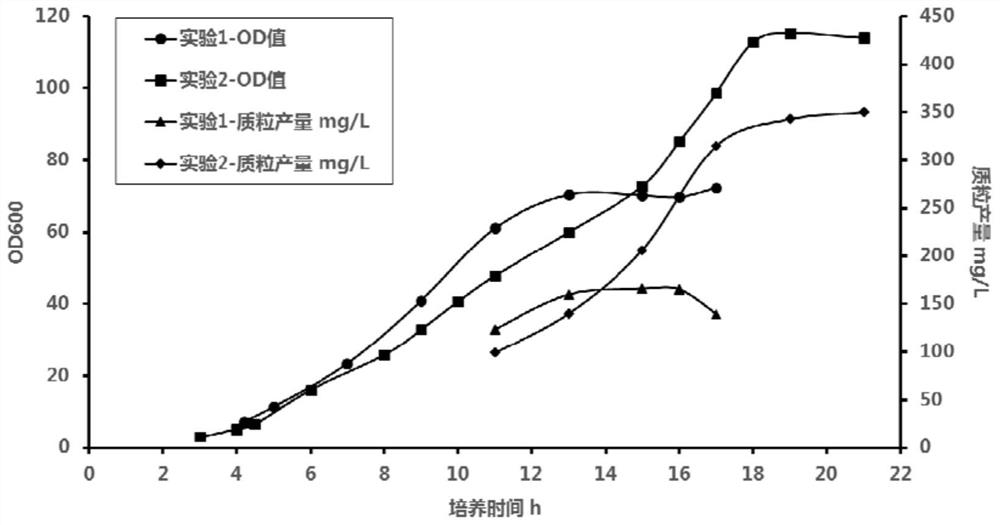

Embodiment 2

[0053] Embodiment 2, the method for limiting growth rate to improve plasmid fermentation yield

[0054] The method for increasing the yield of plasmid fermentation by limiting the growth rate provided by the present embodiment comprises the following steps:

[0055] Step 1. Fermentation preparation

[0056] Using a glass fermenter, first calibrate the pH electrode, and install the newly calibrated pH electrode and dissolved oxygen electrode to the corresponding positions; then, install the exhaust and condensate pipes, acid bottles, lye bottles, and Sigma’s silicone disinfectant. The foam bottle, the feed bottle of feed medium A and feed medium B and the pipelines were installed in the corresponding positions of the fermenter, and sterilized at 121°C for 40 minutes.

[0057] Step 2. Fermentation tank parameter setting

[0058] Pour 1.2L of the prepared initial culture medium into the fermenter, sterilize at 121°C for 30 minutes. After the fermenter is cooled, transfer the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com