Pipeline type photobioreactor for culturing microalgae in multi-nutrition mode and using method of pipeline type photobioreactor

A photobioreactor, multi-nutrient technology, applied in photobioreactors, bioreactors/fermenters for specific purposes, methods of supporting/immobilizing microorganisms, etc., can solve problems such as increased cost and easy contamination of culture solution , to achieve the effect of improving yield, achieving high content accumulation, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

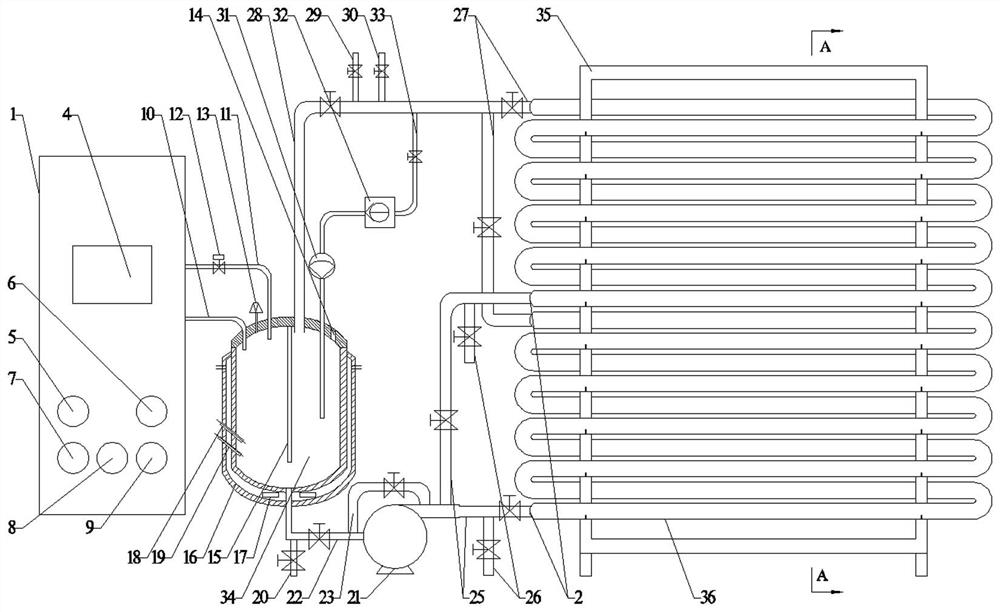

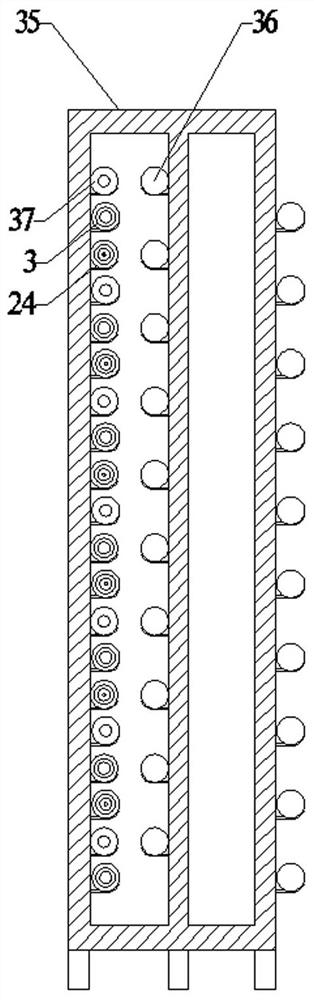

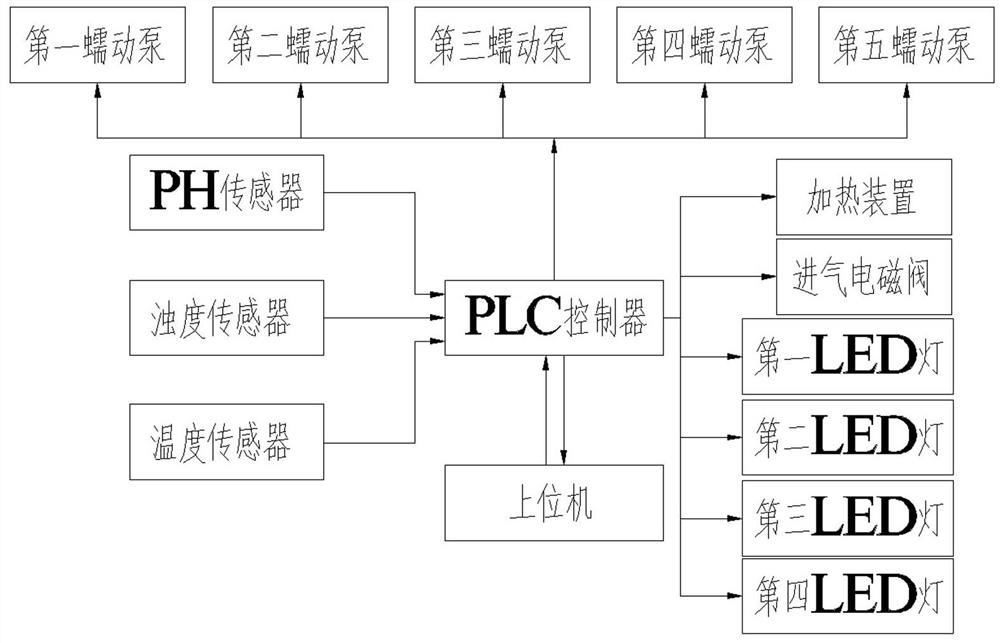

[0036] A pipeline type photobioreactor for cultivating microalgae in a multi-nutrient mode of the present invention includes 2 groups of reaction units and circulation units arranged at different heights of the pipe frame 35; each group of reaction units includes The number of the five transparent pipes 36 in the front row and the transparent pipes 36 in the five rear rows arranged on the pipe frame are the same and the two are arranged in a staggered manner. The transparent pipes 36 in the front row and the transparent pipes 36 in the rear row pass through Elbows are connected successively to form spiral pipes; on the pipe frame 35, an external LED light source is arranged between the transparent pipes 36 in the front row and the transparent pipes 36 in the back row or on the rear side of the transparent pipes 36. The LED light source includes several groups of LED lamp groups arranged at different heights, and the LED lamp groups include the second LED lamp 37, the third LED ...

Embodiment 2

[0050] The difference between this embodiment and Example 1 is that the method of use is the method of use when Haematococcus pluvialis is cultured concurrently;

[0051] Include the following specific steps:

[0052] 1. The reactor is sterilized for the first time including the sterilization of the buffer tank 34 and the sterilization of the reaction unit; the specific steps are to pass the steam from the circulation main pipe 28 into the buffer tank 34 successively through the steam pipeline 29, and from the discharge pipelines of each reaction unit 27 into the transparent pipe 36 of the reaction unit, steam and condensed liquid are discharged from the buffer tank 34 and the reaction unit from the discharge branch pipe 20 and the sampling pipeline 26 respectively, and the reactor sterilization operation is completed;

[0053] 2. Carry out the configuration of the concurrent culture medium, comprising the following steps: add 200L of tap water in the buffer tank 34 through th...

Embodiment 3

[0062] The difference between this embodiment and Example 1 is that the method of use is the method of use when Haematococcus pluvialis is cultured heterotrophically;

[0063] Include the following specific steps:

[0064] 1. The reactor is sterilized for the first time including the sterilization of the buffer tank 34 and the sterilization of the reaction unit; the specific steps are to pass the steam from the circulation main pipe 28 into the buffer tank 34 successively through the steam pipeline 29, and from the discharge pipelines of each reaction unit 27 into the transparent pipe 36 of the reaction unit, steam and condensed liquid are discharged from the buffer tank 34 and the reaction unit from the discharge branch pipe 20 and the sampling pipeline 26 respectively, and the reactor sterilization operation is completed;

[0065] 2. Carry out the configuration of the concurrent culture medium, comprising the following steps: add 200L of tap water in the buffer tank 34 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com