Method and apparatus for controlling operation of a spark-ignition direct-injection engine

A spark ignition, internal combustion engine technology, applied in engine components, engine control, machine/engine, etc., to solve problems such as reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

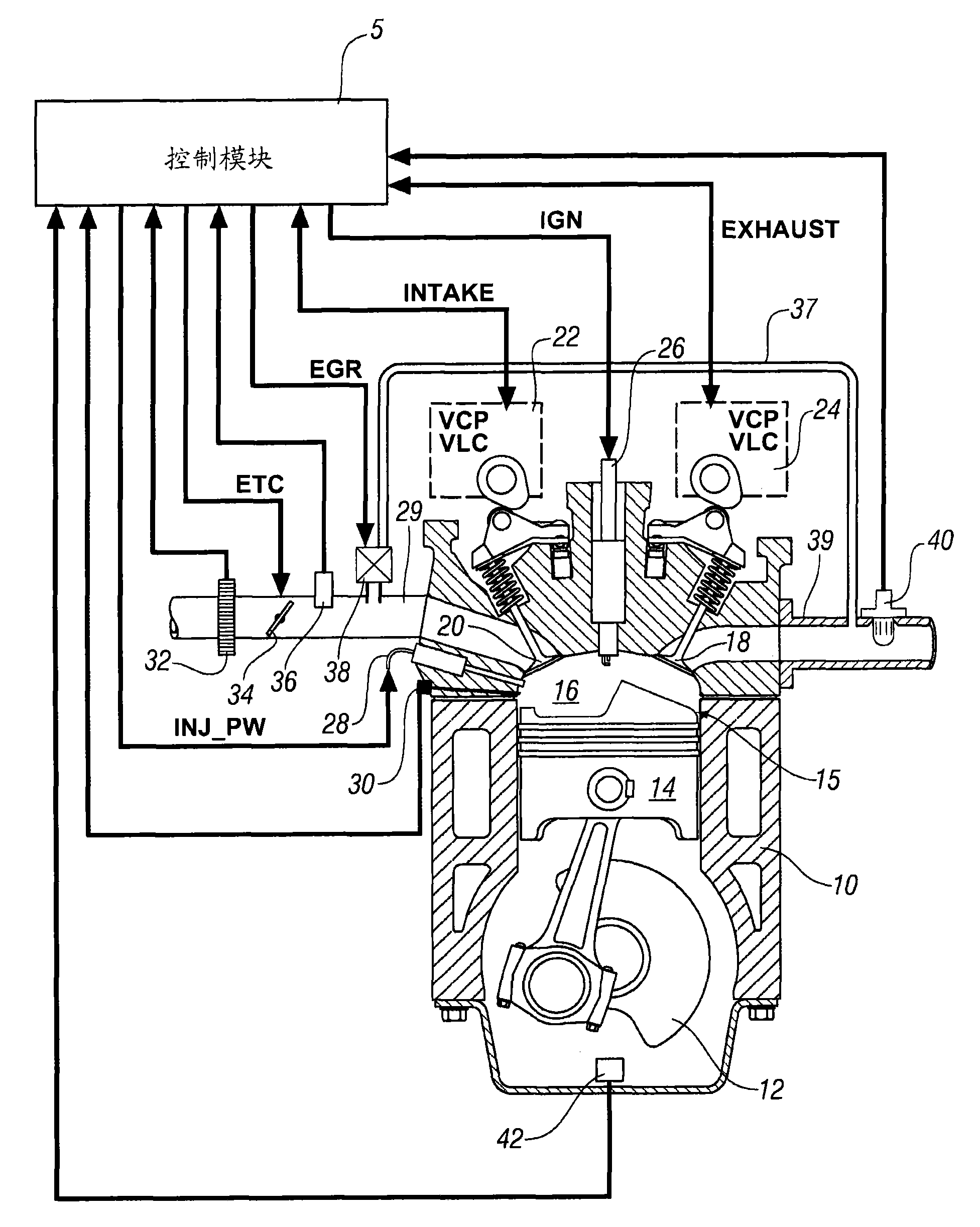

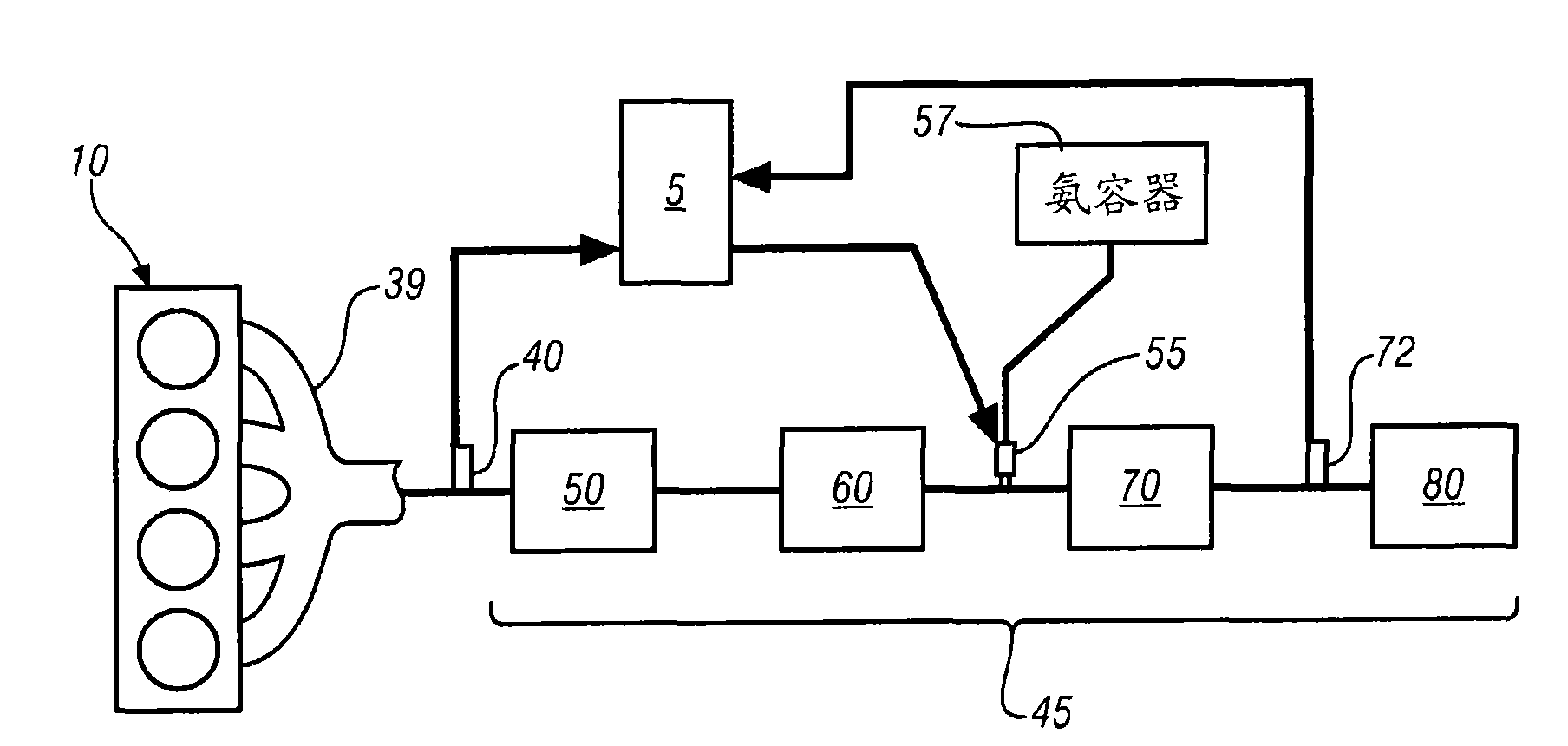

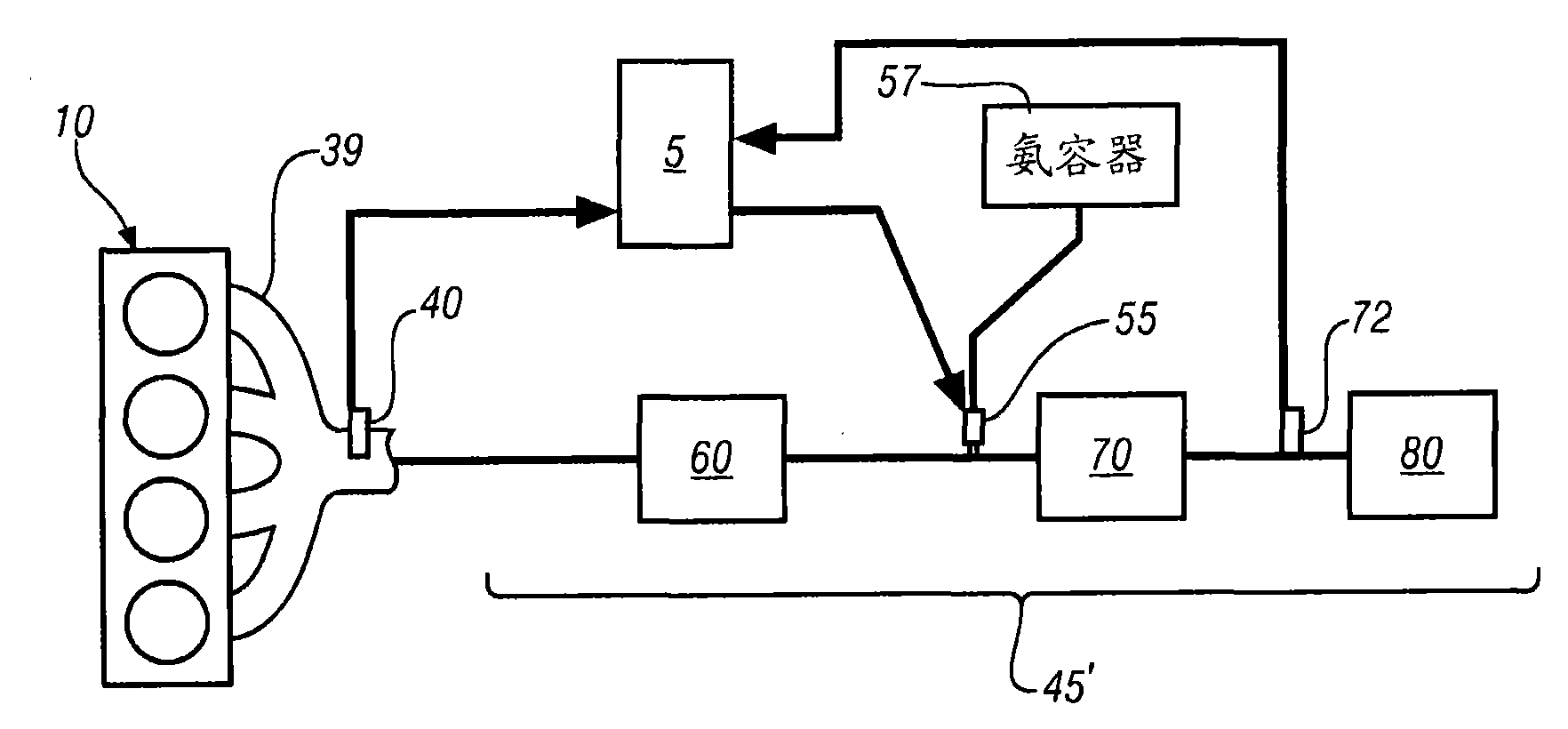

[0013] Referring now to the drawings, wherein said drawings are for the purpose of illustrating certain exemplary embodiments only and are not intended to limit the present invention, figure 1 , figure 2 , image 3 and Figure 4 An internal combustion engine 10 constructed in accordance with an embodiment of the present invention, an exhaust aftertreatment system 45, 45' and accompanying control systems implemented in the control module 5 are shown schematically. The same reference numerals in the figures refer to the same elements.

[0014] figure 1 Engine 10 is shown comprising a multi-cylinder direct injection four-stroke internal combustion engine having a reciprocating piston 14 slidably movable within cylinders 15 defining a variable volume combustion chamber 16 . Each piston 14 is connected to a rotating crankshaft 12 by which linear reciprocating piston travel is converted into rotary motion. A single one of cylinders 15 is shown. Exemplary engine 10 may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com