Auxiliary support device

A technology of auxiliary support and support frame, which is applied in sawing machine devices, metal sawing equipment, sawing equipment, etc., can solve the problems of occupation and large space, and can increase the support surface, facilitate storage or transportation, and reduce the packaging volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

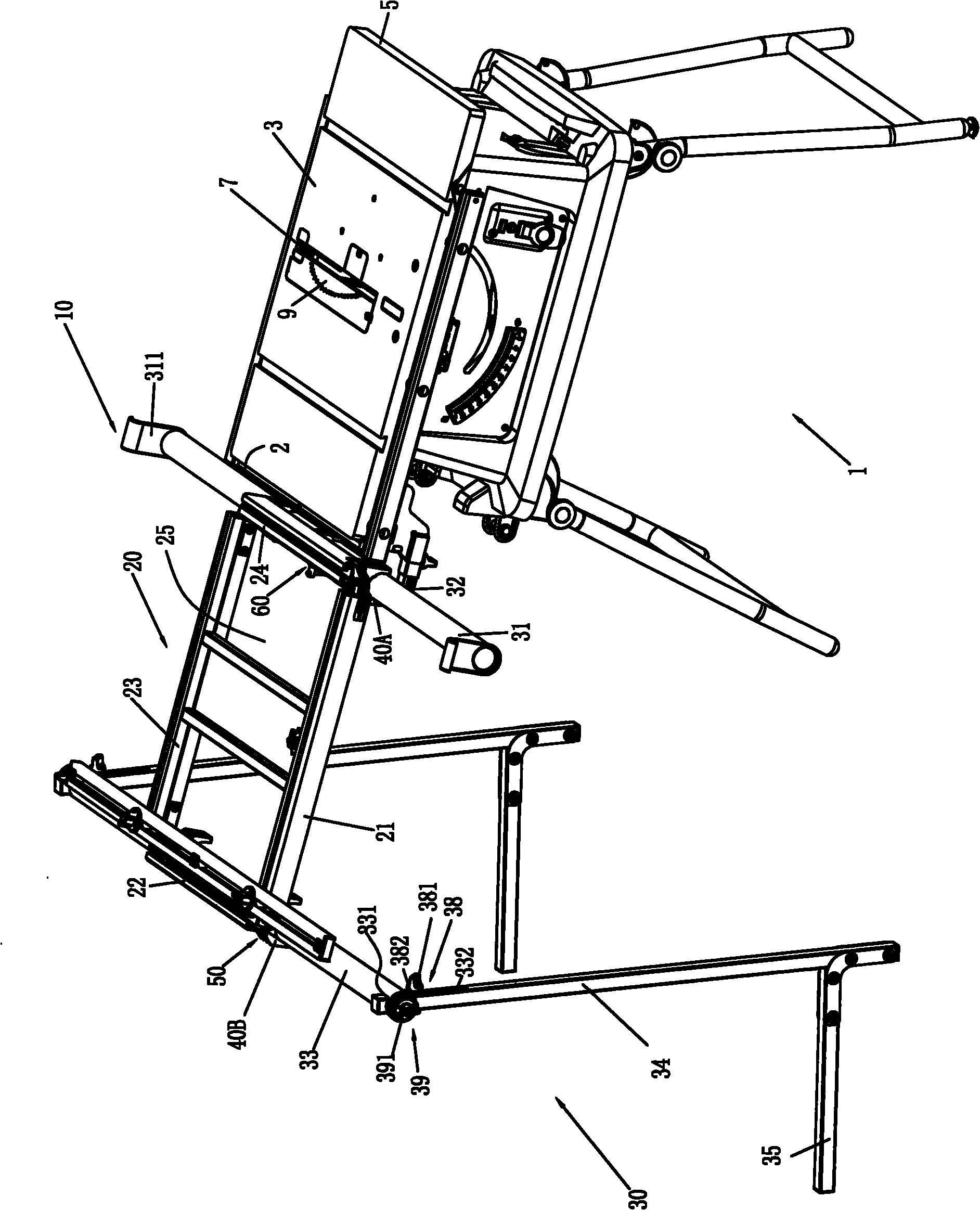

[0065] see Figures 1 to 9d Shown, the first preferred embodiment of the present invention.

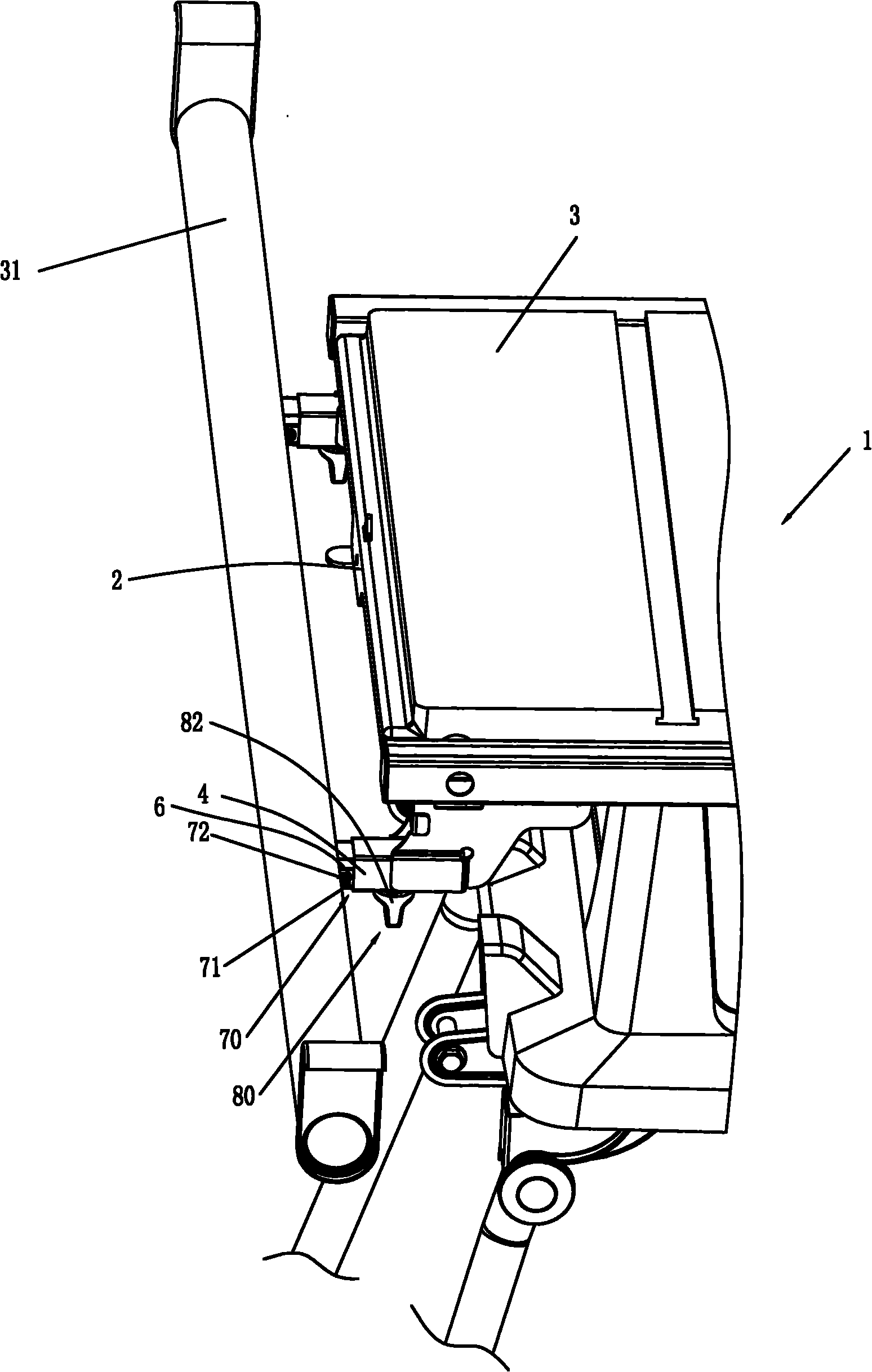

[0066] Such as figure 1 As shown, the auxiliary support device 10 can be applied to a desktop electric tool, and the traditional desktop electric tool can be a table saw, an electric wood milling workbench, and the like. In this embodiment, the bench-type power tool is a table saw 1 having a main table 5 with a main work surface 3 . The main table 5 includes a slot or hole 7 extending through the main table 5 . The saw blade 9 is mounted in a conventional manner on a motor and bracket (not shown) located below the main table 5 . A portion of the saw blade 9 passes through the slot 7 and protrudes for cutting the workpiece.

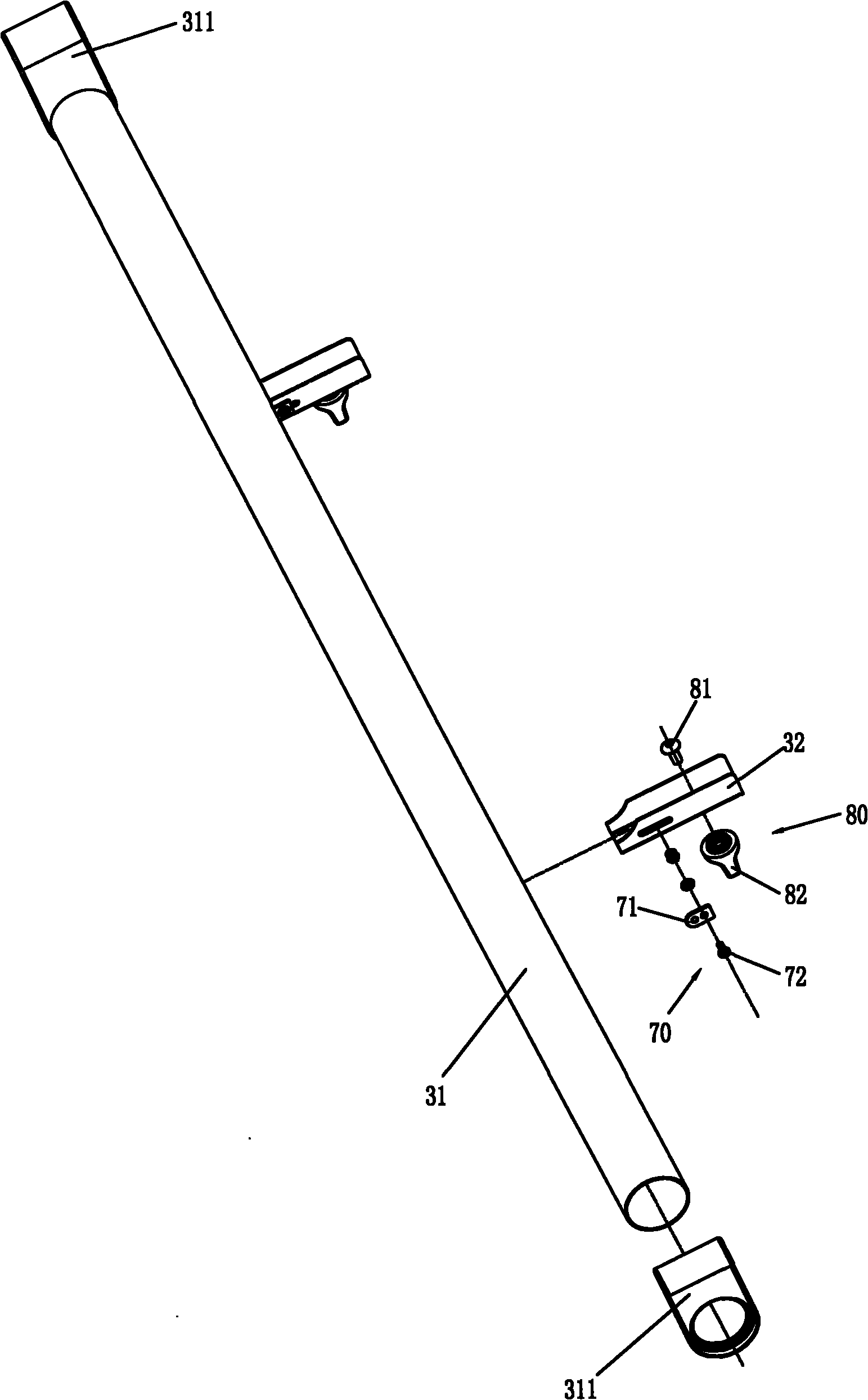

[0067] The auxiliary supporting device 10 comprises an auxiliary workbench 20 having an auxiliary workbench 25, and a support structure 30 supporting the auxiliary workbench 20. The support structure 30 can make the auxiliary workbench 25 and the main workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com