Compound parabolic condenser combining inside condensation and outside condensation

A compound paraboloid and concentrator technology, applied in the field of solar energy concentrating, can solve problems such as too large gap between the concentrating plate and the receiving tube, difficult maintenance of the concentrating plate, difficulty in manufacturing and installation, etc., so as to facilitate large-scale industrial production and avoid solar energy Effects of loss, ease of installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

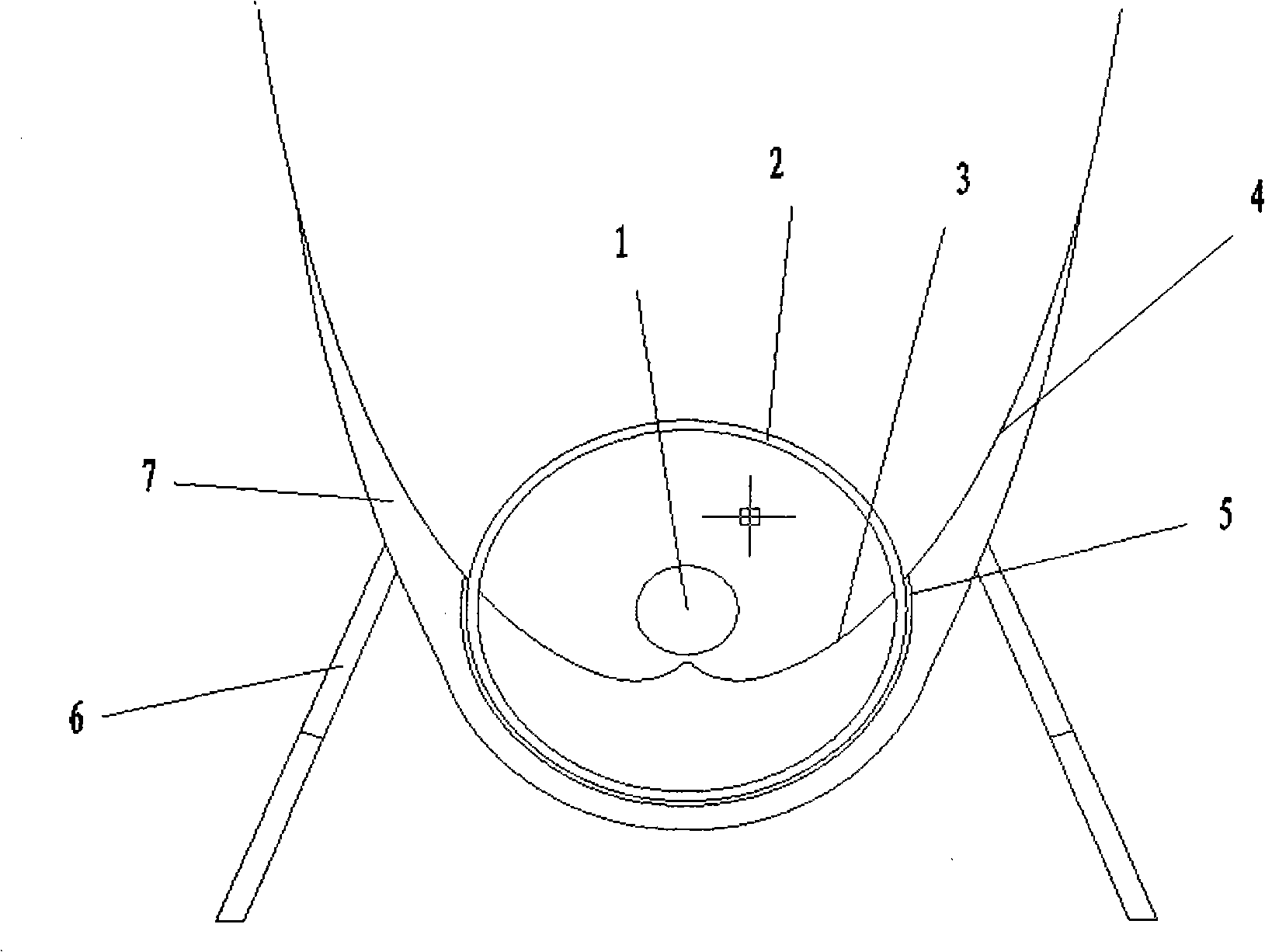

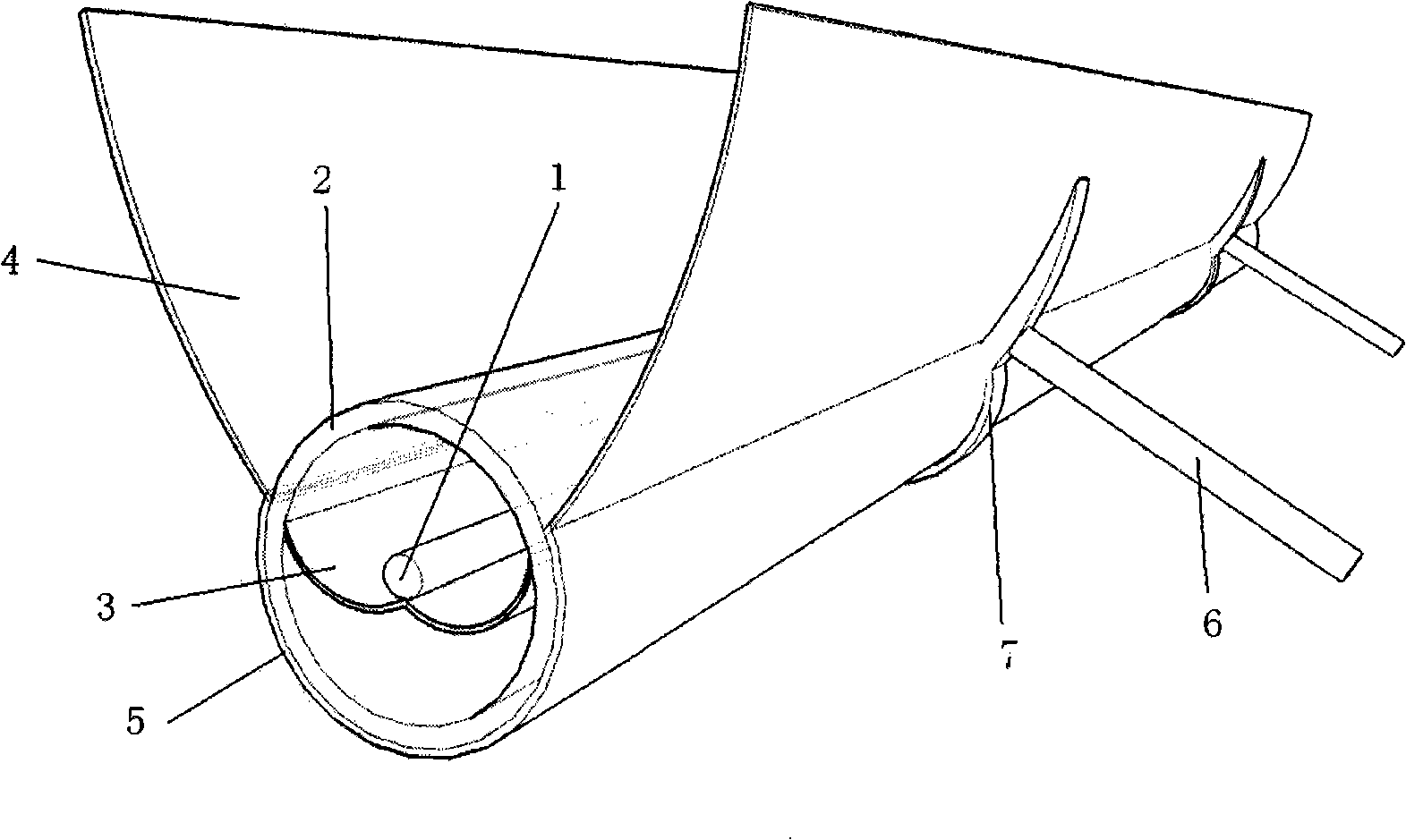

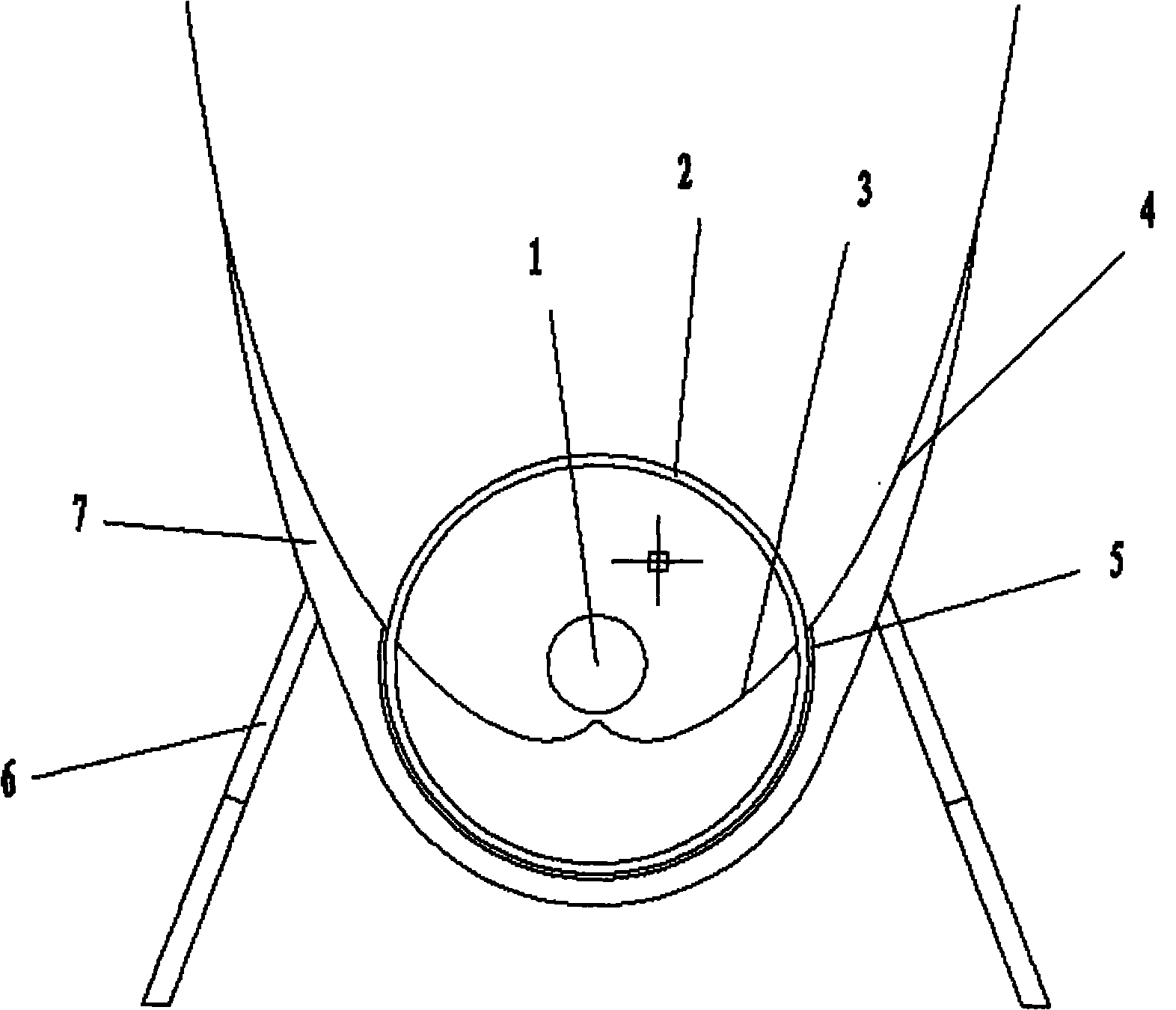

[0037] like figure 1 and figure 2 , the length of glass tube 2 and receiving tube 1 is 2m, the outer diameter of the glass tube is 120mm, the inner diameter is 114mm, the receiving tube 1 is a heat pipe, and the outer diameter of the tube is 28mm; the maximum receiving angle is 20°, and the width of the daylight opening is 235mm. The glass tube 2 is fixed by two supporting beams 7 and supported by two supporting feet 6. Adjust the supporting feet 6 so that the opening of the external compound parabolic concentrating plate 4 is inclined at an angle of about 30° to the south. When sunlight is received by the concentrator The light energy is incident on the opening surface within the angular range, and the light energy passes through the glass tube 2 directly or after being reflected by the external compound parabolic concentrating plate 4, and finally reaches the receiving tube 1 directly or after being reflected by the internal compound parabolic concentrating plate 3.

Embodiment 2

[0039] Both the glass tube 2 and the receiving tube 1 are 2m in length, the outer diameter of the glass tube is 120mm, and the inner diameter is 114mm. The receiving tube 1 is a straight-through tube with an outer diameter of 35mm; the maximum receiving angle is 30°, and the width of the lighting opening is 255mm. The glass tube 2 is fixed by two supporting beams 7 and supported by two supporting feet 6. Adjust the supporting feet 6 so that the opening of the external compound parabolic concentrating plate 4 is inclined at an angle of about 30° to the south, and the light energy is directly or through the external compound parabolic concentrating plate 4 After being reflected, it passes through the glass tube 2, and then reaches the receiving tube 1 directly or after being reflected by the internal compound parabolic concentrating plate 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com