Pebble bed high temperature pile ball flow pipeline locker

A high-temperature reactor and latch technology, which is applied in the field of reactor equipment and can solve the problems of fuel element jamming and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

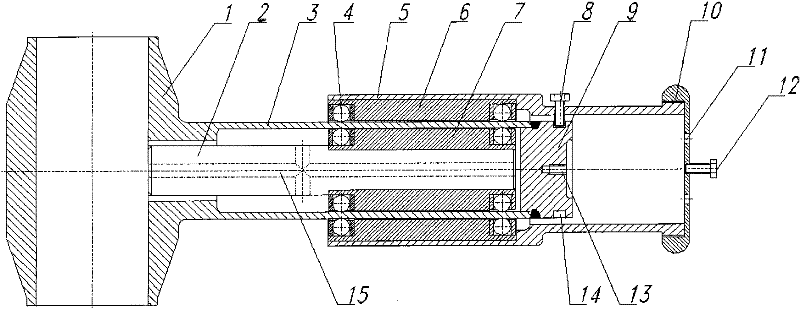

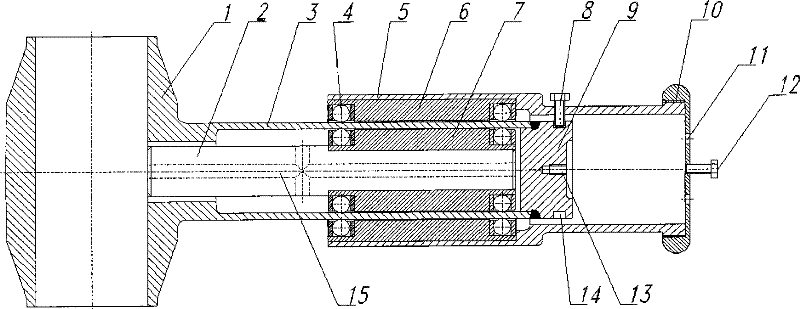

[0019] like figure 1 As shown, the pebble bed high temperature pile ball flow pipeline locker provided by the embodiment of the present invention is arranged on the outside of the ball passing pipe 1, and mainly includes: a lock shaft 2, a pressure bearing shell 3, a ball 4, a jacket 5, and an outer magnetic assembly 6. Inner magnetic group 7, positioning screw 8, head 9, end cover 10, air hole 11, locking screw 12, locking screw hole 13, positioning groove 14, diversion hole 15.

[0020] After connecting the ball joint 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com