Controllable afterflow method of magnetic controlled shunt reactor

A reactor, magnetron technology, applied in the conversion equipment, electrical components, AC power input to AC power output, etc. that can be converted into DC without intermediate conversion, can solve the problems of high overvoltage, rectifier damage, etc., Achieve the effect of reducing excitation current, convenient control and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

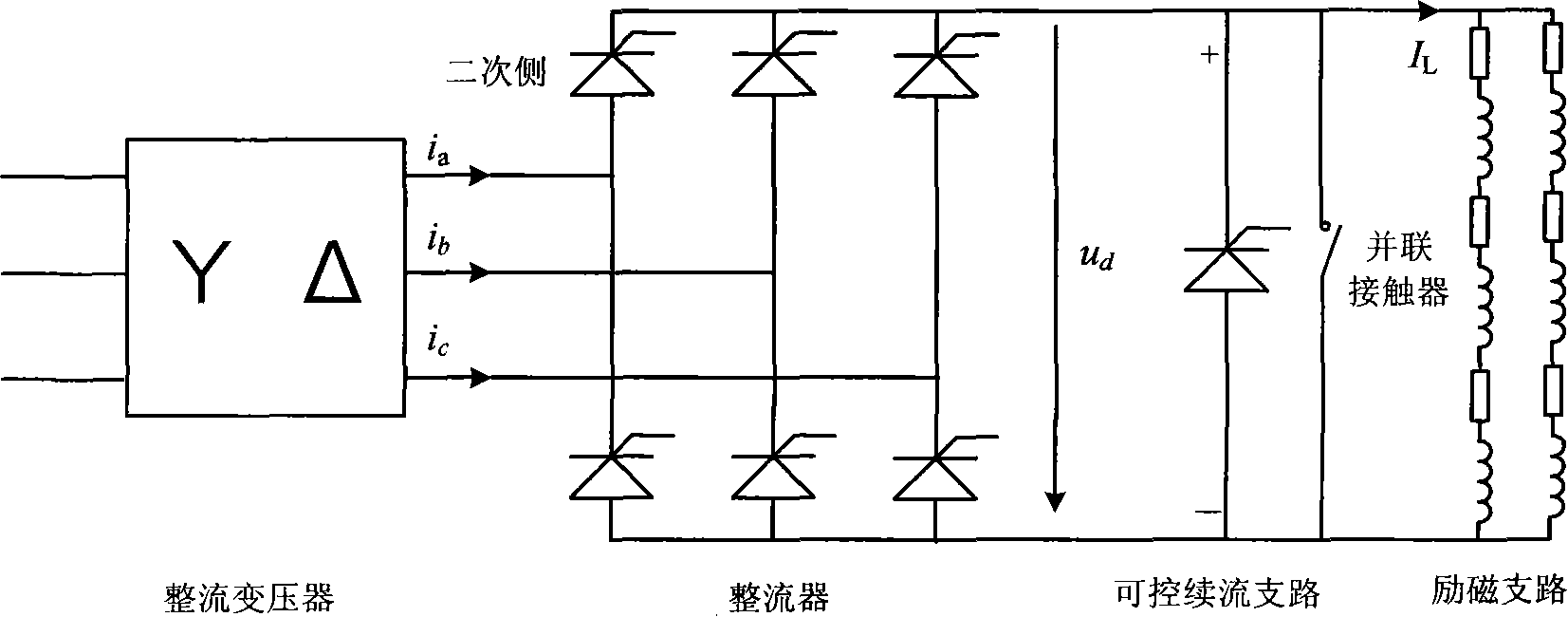

[0011] Such as figure 1 As shown, the controllable freewheeling branch of the magnetic control shunt reactor of the present invention is composed of thyristor valves connected in parallel at the two poles of the DC bus. The cathode of the thyristor valve is connected to the positive pole of the DC bus, and the anode is connected to the negative pole of the DC bus.

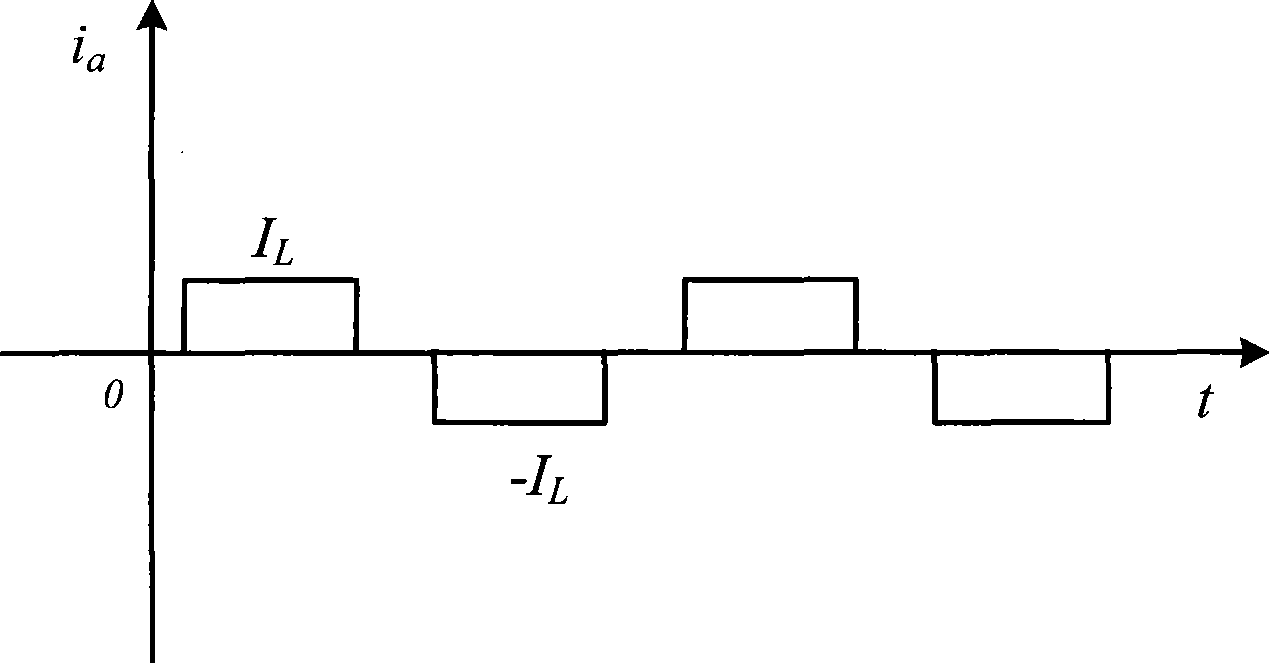

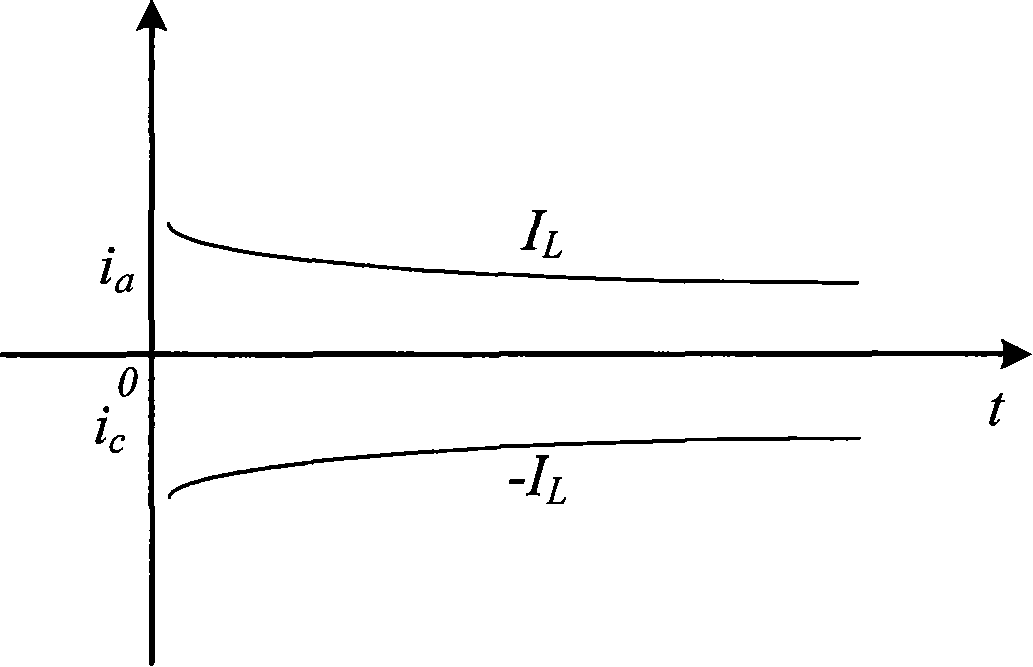

[0012] The controllable freewheeling method of the present invention includes: 1. When the rectifier is in a normal working state, block the trigger pulse of the thyristor valve of the controllable freewheeling branch, and the controllable freewheeling branch is not conducted; When all-phase operation or three-phase tripping occurs, the control circuit (which belongs to the existing mature technology) blocks the trigger pulse of the rectifier and triggers the thyristor valve of the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com