Buck-boost composite DC/DC converter

A converter, buck-boost technology, applied in the field of DC/DC converters with buck-boost composite, can solve problems such as increased switching loss, increased output ripple, and system instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

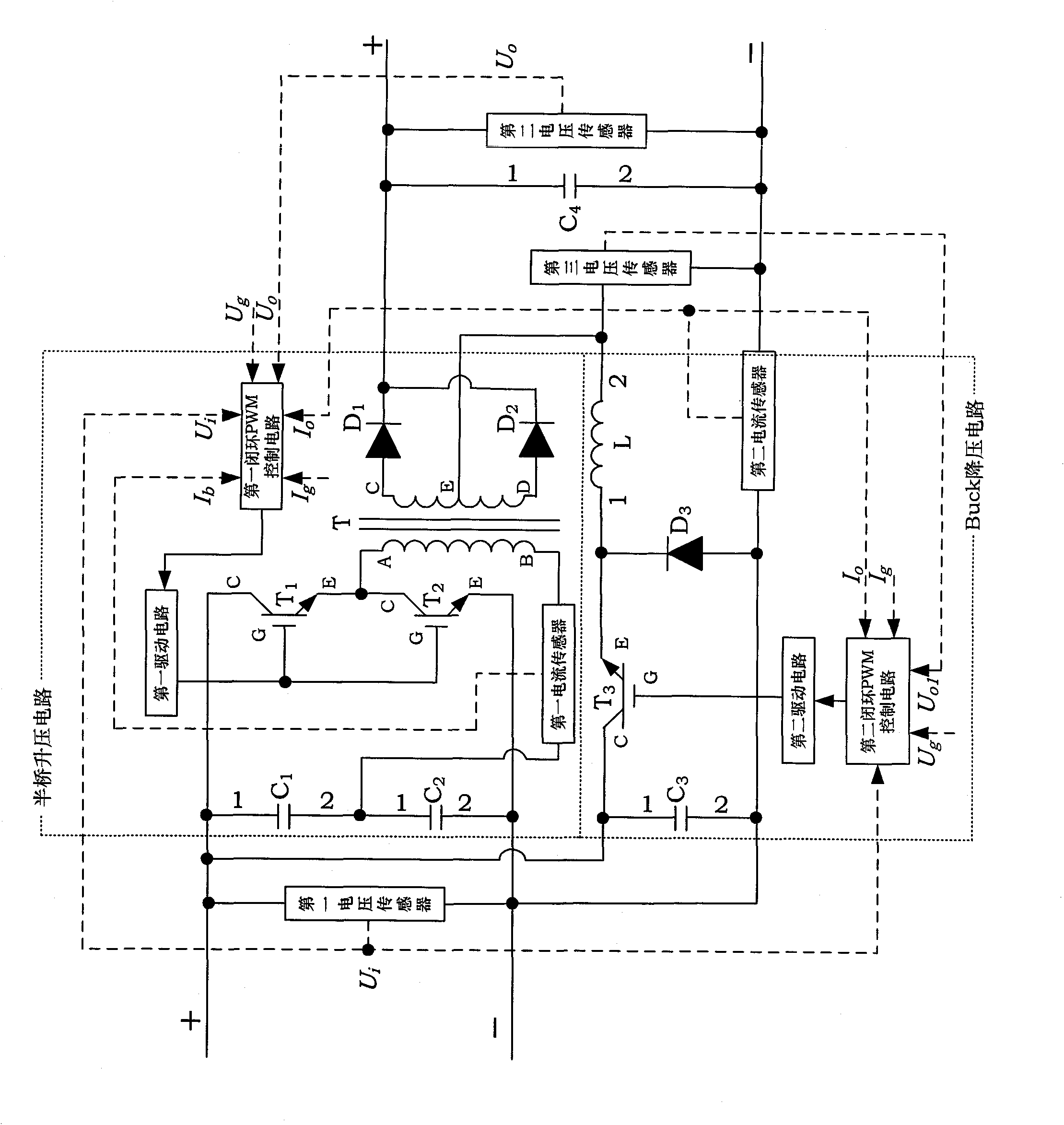

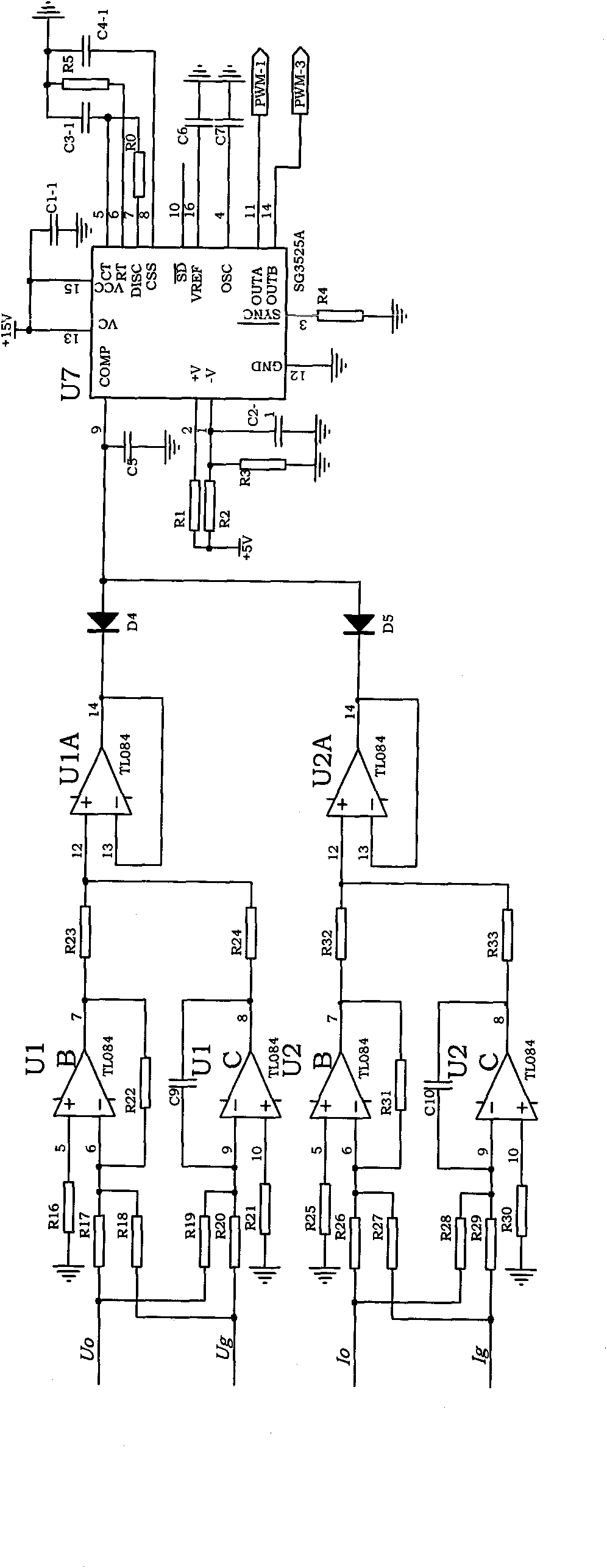

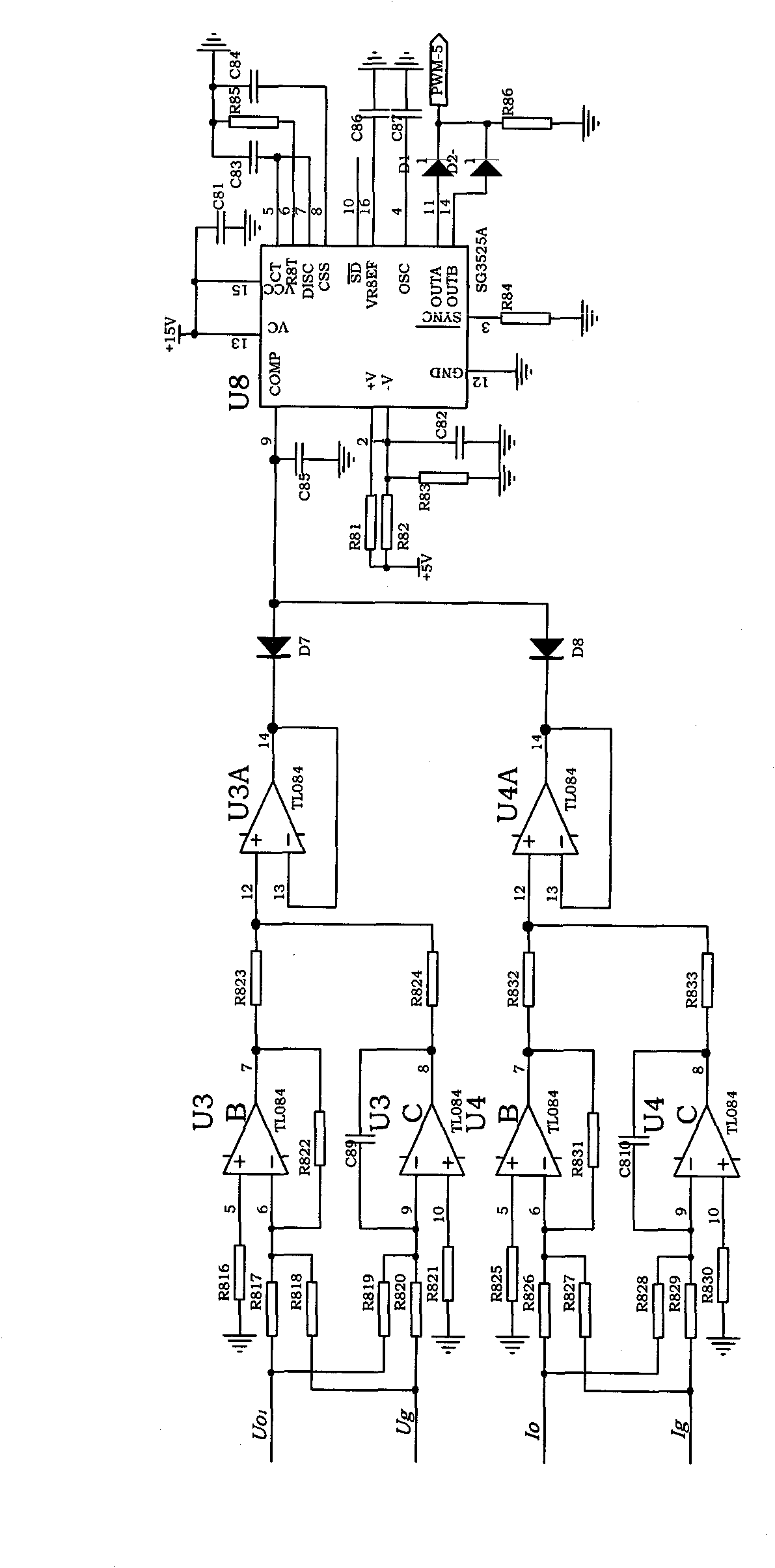

[0025] The present invention relates to a buck-boost composite DC / DC converter combined with a half-bridge and a Buck. The converter includes a Buck step-down circuit, a half-bridge booster circuit, a closed-loop PWM control circuit and a drive circuit.

[0026] In the present invention, the Buck step-down circuit is composed of the third filter capacitor C 3 , the third power switch tube T 3 , the third diode D 3 And filter inductance L composition.

[0027] In the present invention, the half-bridge boost circuit is composed of the first filter capacitor C 1 , the second filter capacitor C 2 , the first power switch tube T 1 , the second power switch tube T 2 , transformer T, first diode D 1 and the second diode D 2 composition.

[0028] In the present invention, the input stages of the Buck step-down circuit and the half-bridge booster circuit are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com