Ladle tilting mechanism

A technology of tipping mechanism and ladle, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc. It can solve the problems of difficult operation of the crane, long operation time of the crane, wear of the ladle trunnion, etc., and achieves a compact structure , Reduce the difficulty of operation and reduce the effect of taking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

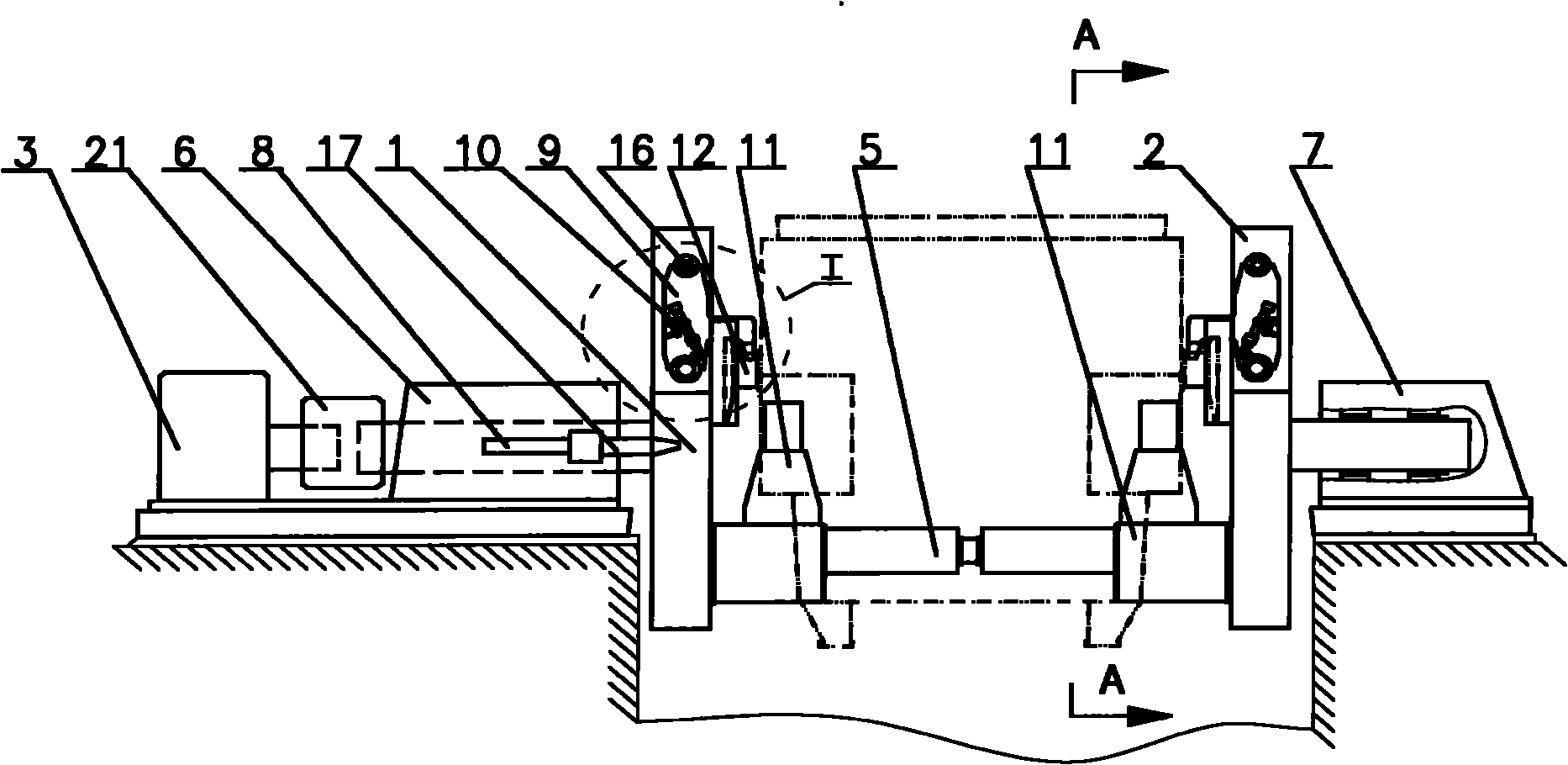

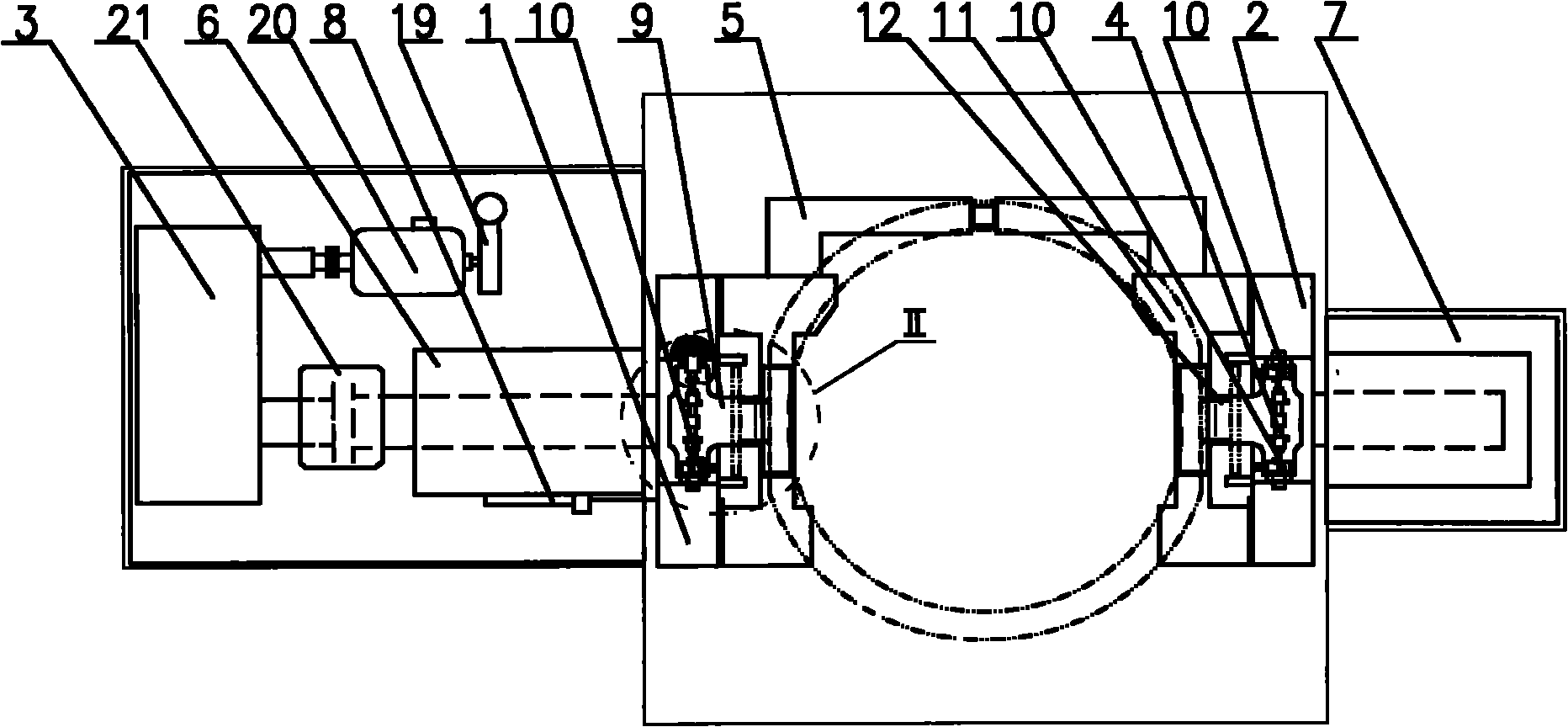

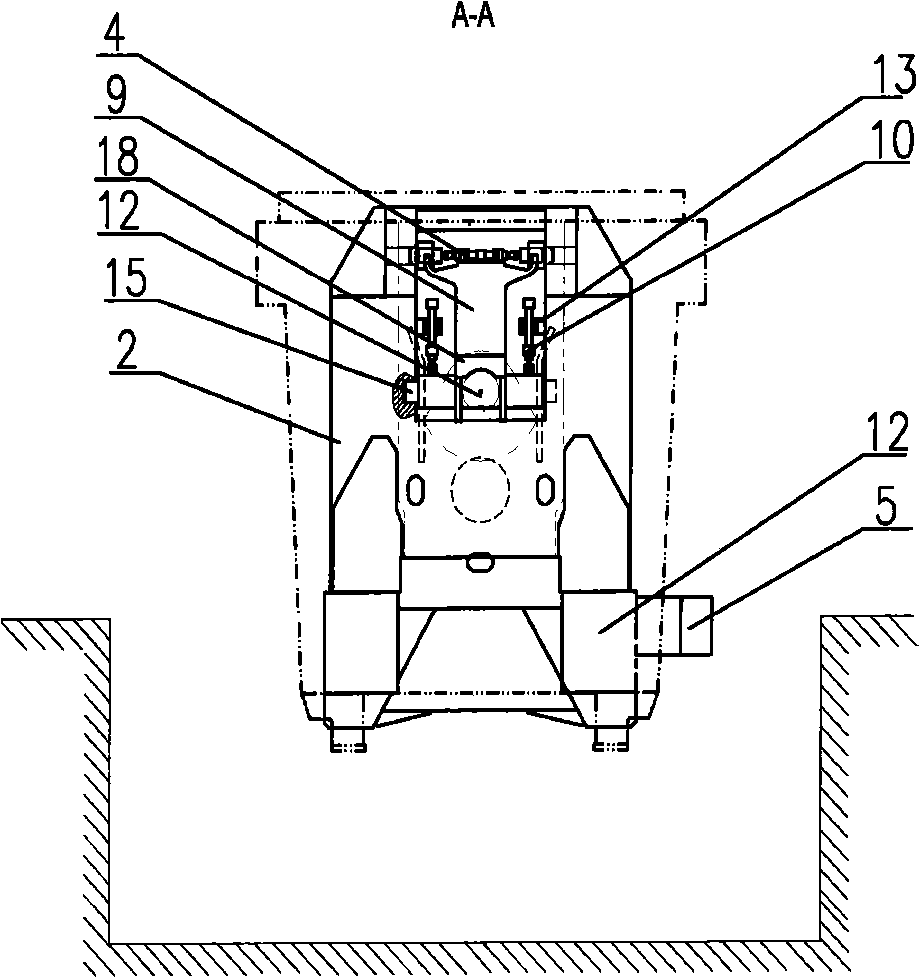

[0021] figure 1 , 2 , 3, 4, and 5 show specific embodiments of the present invention, which are a kind of ladle tipping mechanism installed in a large-scale steelmaking workshop; it is characterized in that: in the foundation pit, circular trunnions 12 supporting ladle both sides are symmetrically installed The U-shaped mount 11 is connected with the connecting beam 5 at the rear side between the two U-shaped mounts 11, wherein the U-shaped mount 11 on the left side is connected with the driving tipping frame 1, and the U-shaped mount 11 on the right is connected with the The moving tilting frame 2 is connected; the concentric rotating shaft is connected at the center of the outer surface of the driving tilting frame 1 and the driven tilting frame 2, and the rotating shaft of the driven tilting frame 2 is packed into the driven side rotary bracket 7 In the shaft hole, the rotating shaft of the driving tipping frame 1 is connected to the output shaft in the electric transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com