Peroxide supplying system and safety operation method

A hydrogen peroxide and supply system technology, applied in the direction of compressed gas generation, attack equipment, etc., can solve problems such as high cost of use, high toxicity, human health and environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

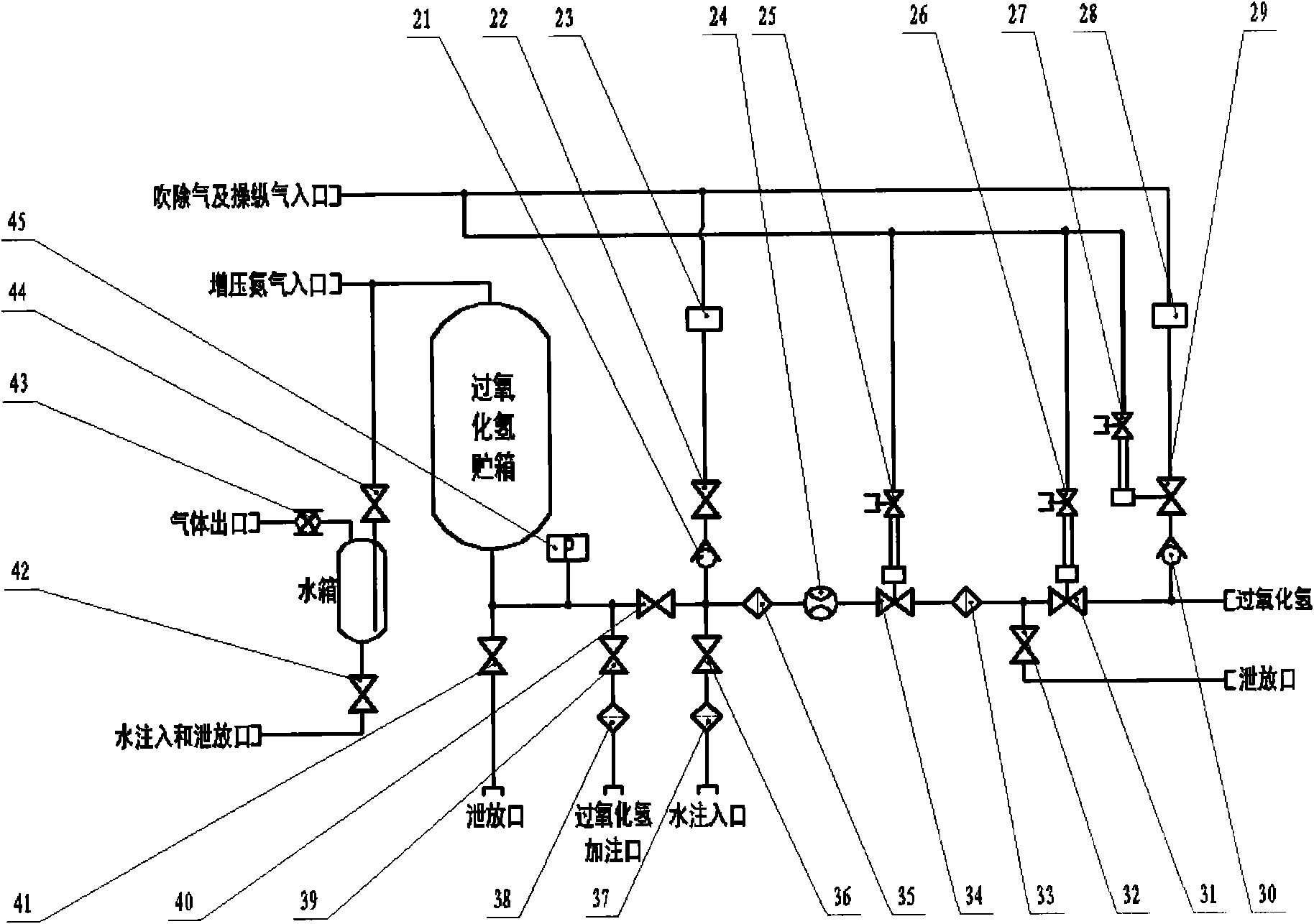

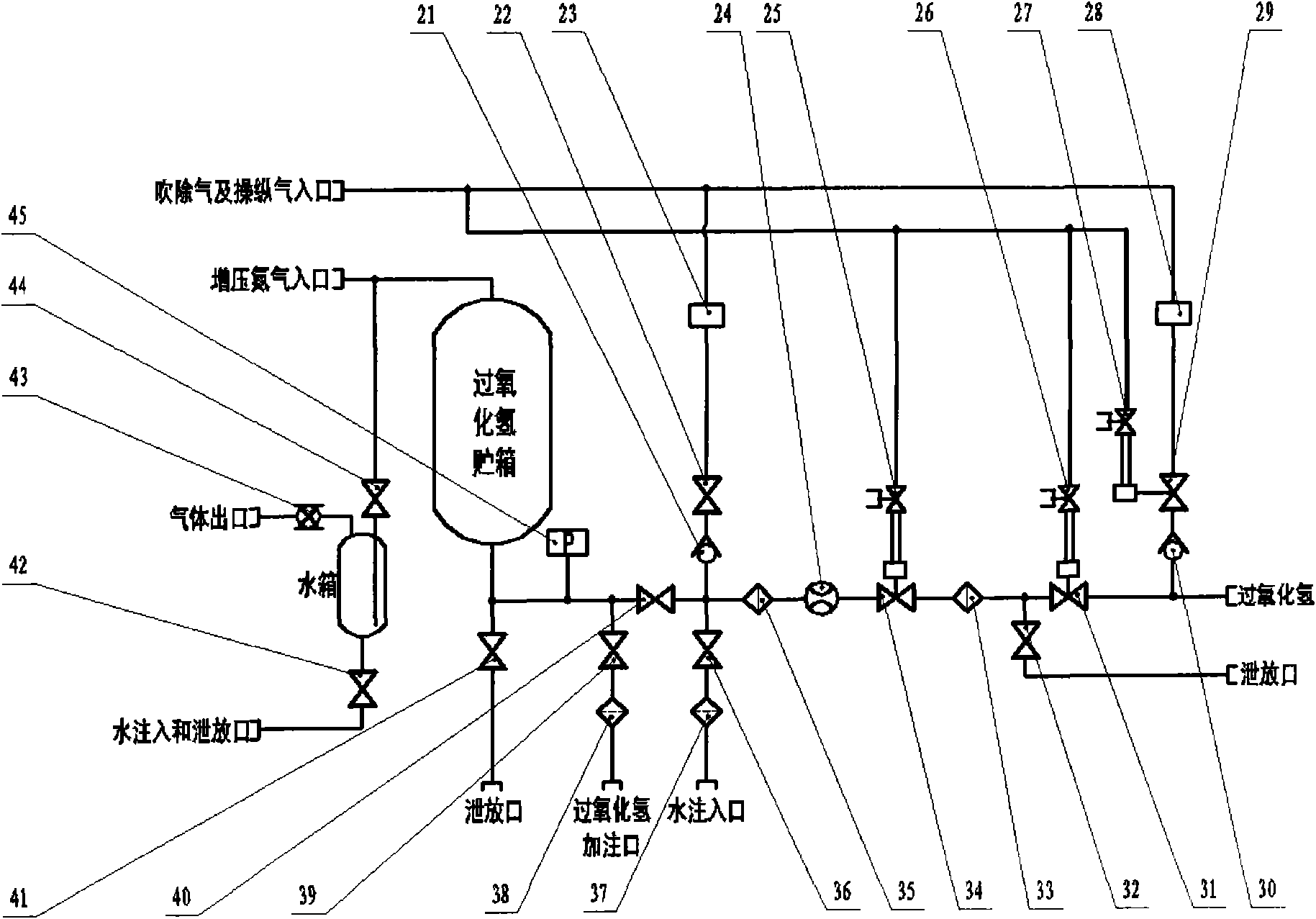

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

[0008] The operating console of the hydrogen peroxide supply system and the pipeline system are placed in different rooms, and the two are connected through pipelines to avoid direct contact between the operator and the hydrogen peroxide supply system and improve the safety of the operator.

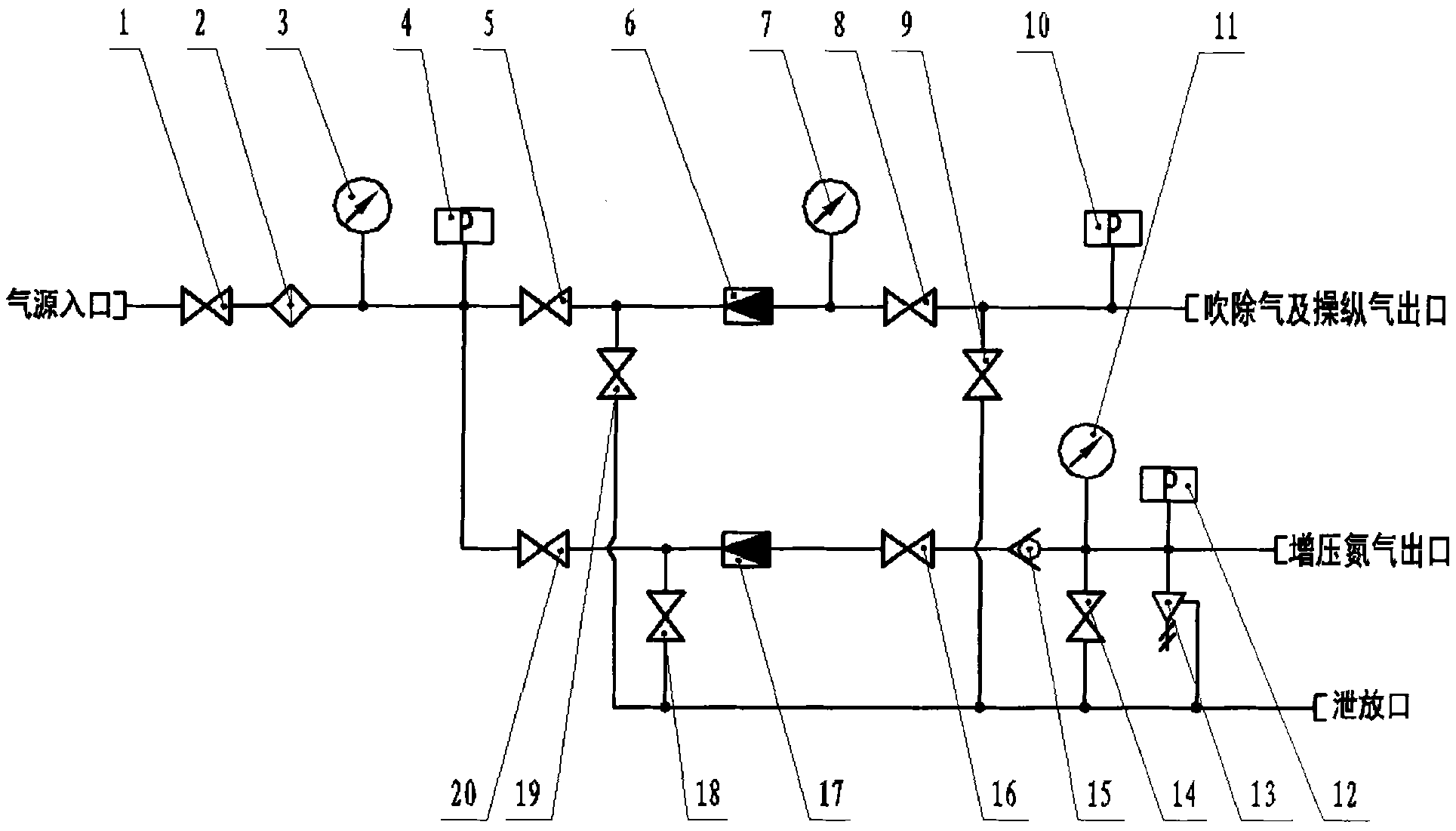

[0009] 1. The specific operation mode of the console

[0010] like figure 1 As shown, the gas inlet and outlet of the console include gas source inlet, purge gas and control gas outlet, pressurized gas outlet, and bleed gas outlet. The nitrogen supplied through the gas source inlet meets the nitrogen demand of the entire system. During operation, firstly open the manual shut-off valve 1, the gas source gas communicates with the console, and the pressure of the gas source can be monitored through the pressure gauge 3 and the pressure sensor 4. Filter 2 is used to prevent possible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com