Universal joint

A technology of universal joints and ball joints, applied in the field of universal joints, which can solve problems such as poor clamping effect, easy shaking during use, and poor anti-torsion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

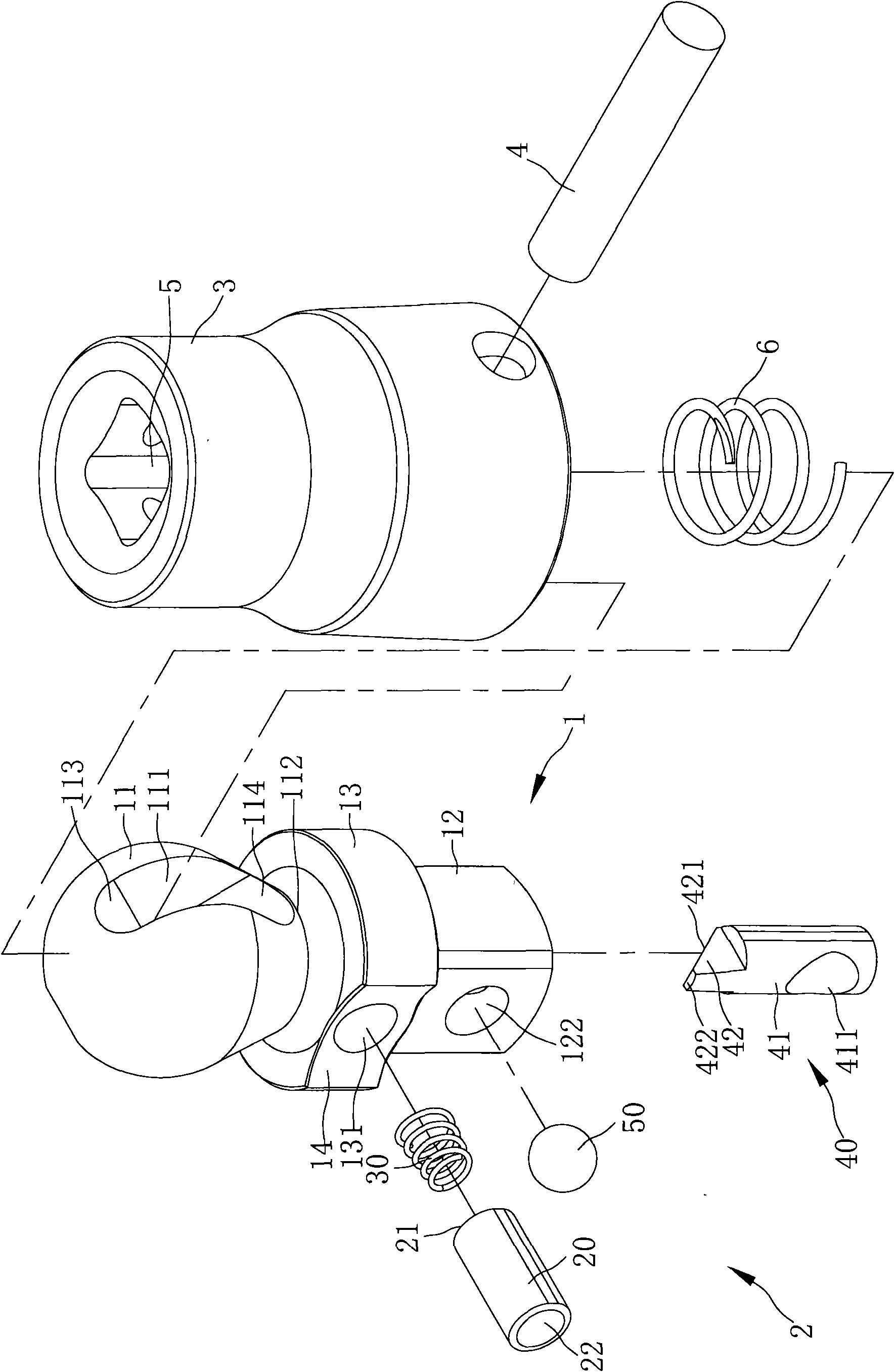

[0030] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

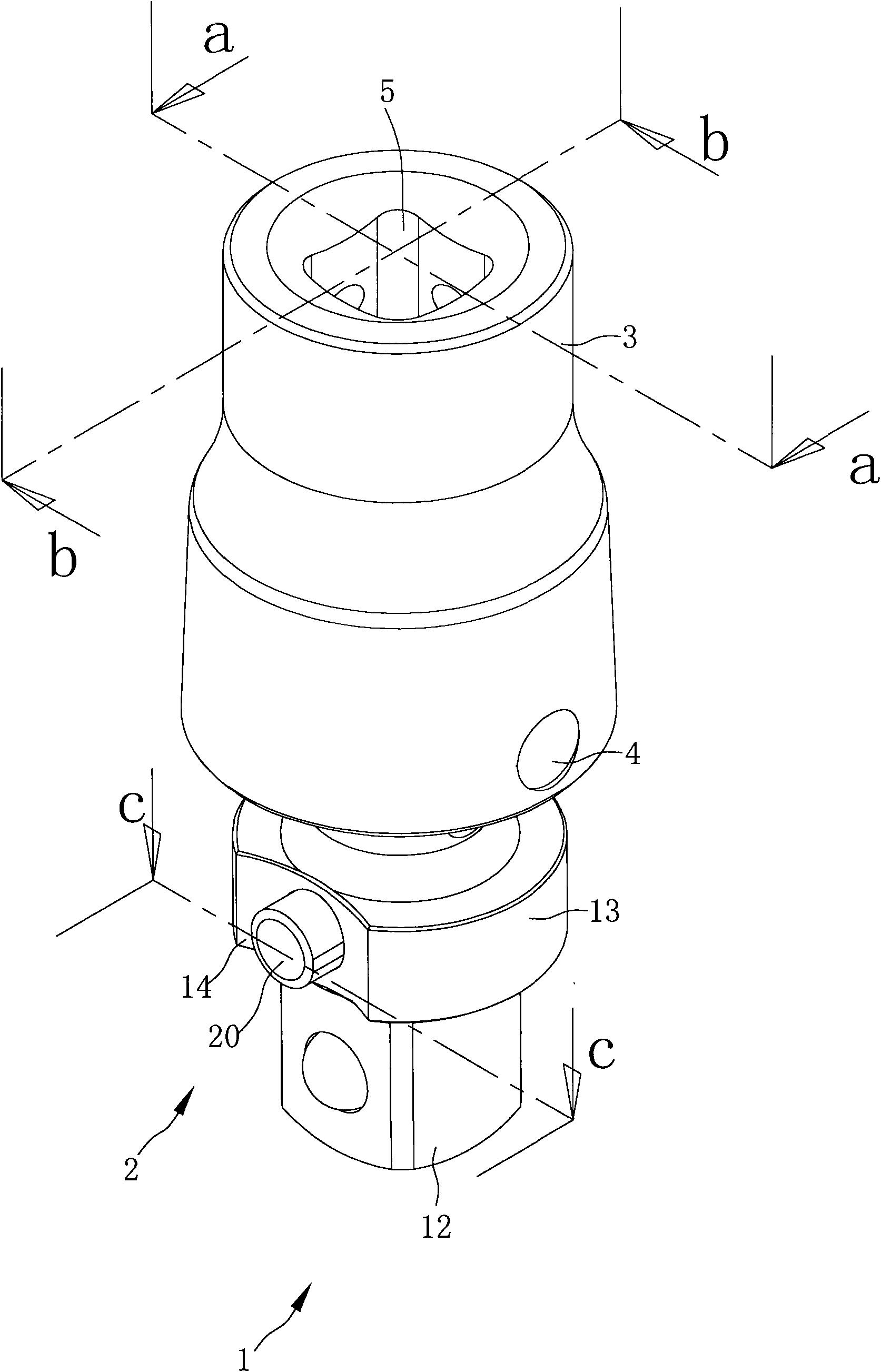

[0031] refer to figure 1 , is a three-dimensional appearance view of the universal joint of the present invention. The universal joint of the present invention includes a body 1, a control device 2 and a linkage 3;

[0032] One end of the link 3 is provided with a drive hole 5 for connecting a power tool, such as an air tool or an electric tool, so that the link 3 can be driven by the power tool to rotate.

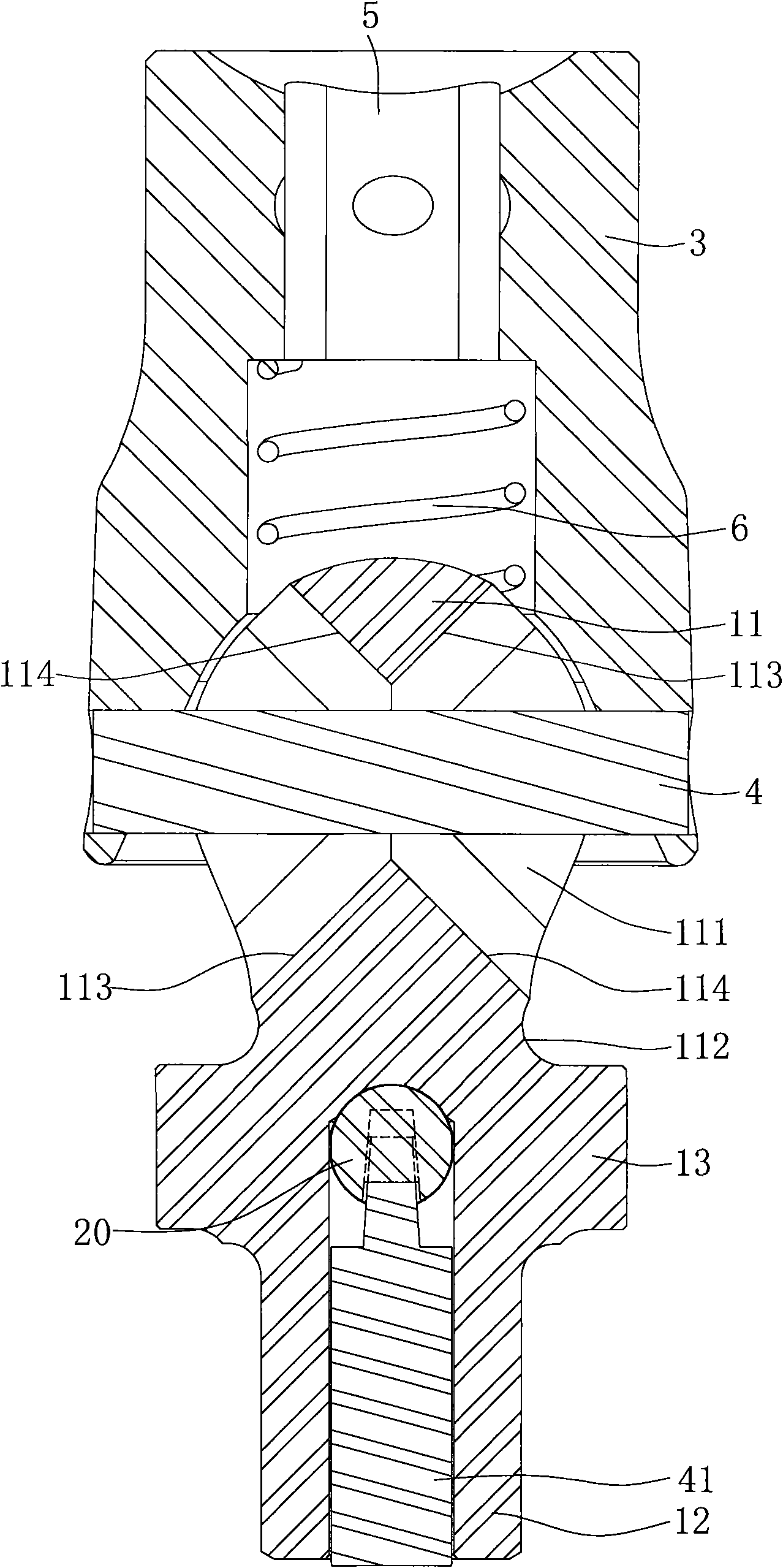

[0033] refer to Figure 2 to Figure 4 , the body 1 has a ball head 11 and a drive head 12, the ball head 11 is provided with a through hole 111 with an elliptical cross section (such as Figure 4 ), the through hole 111 can be pivotally connected to the linkage 3 through a pin 4, forming a complete universa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com