Manual operating mechanism for opening and closing of dropout type fuse and fuse carrier

A drop-type fuse, manual operation technology, applied in the direction of protection switch operation/release mechanism, electrical components, circuits, etc., can solve problems such as unclear vision, small ring pull ring, inconvenience, etc., to achieve convenient operation and operation. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

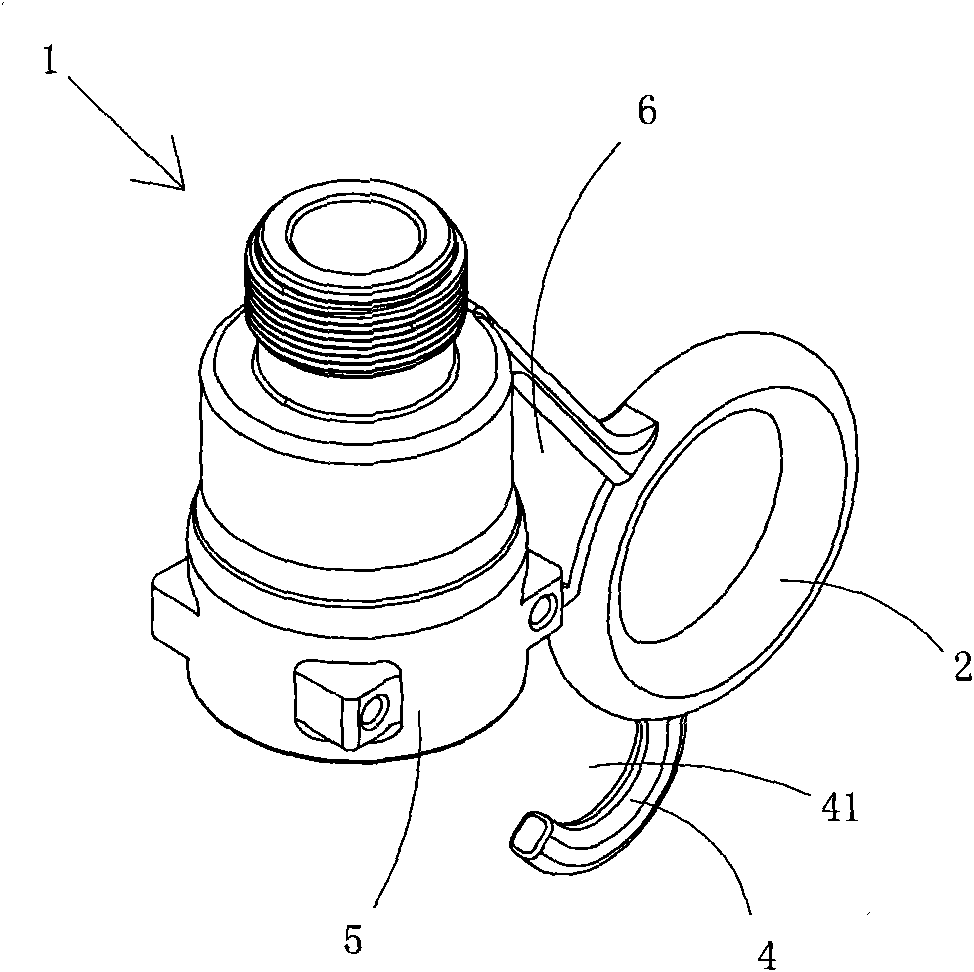

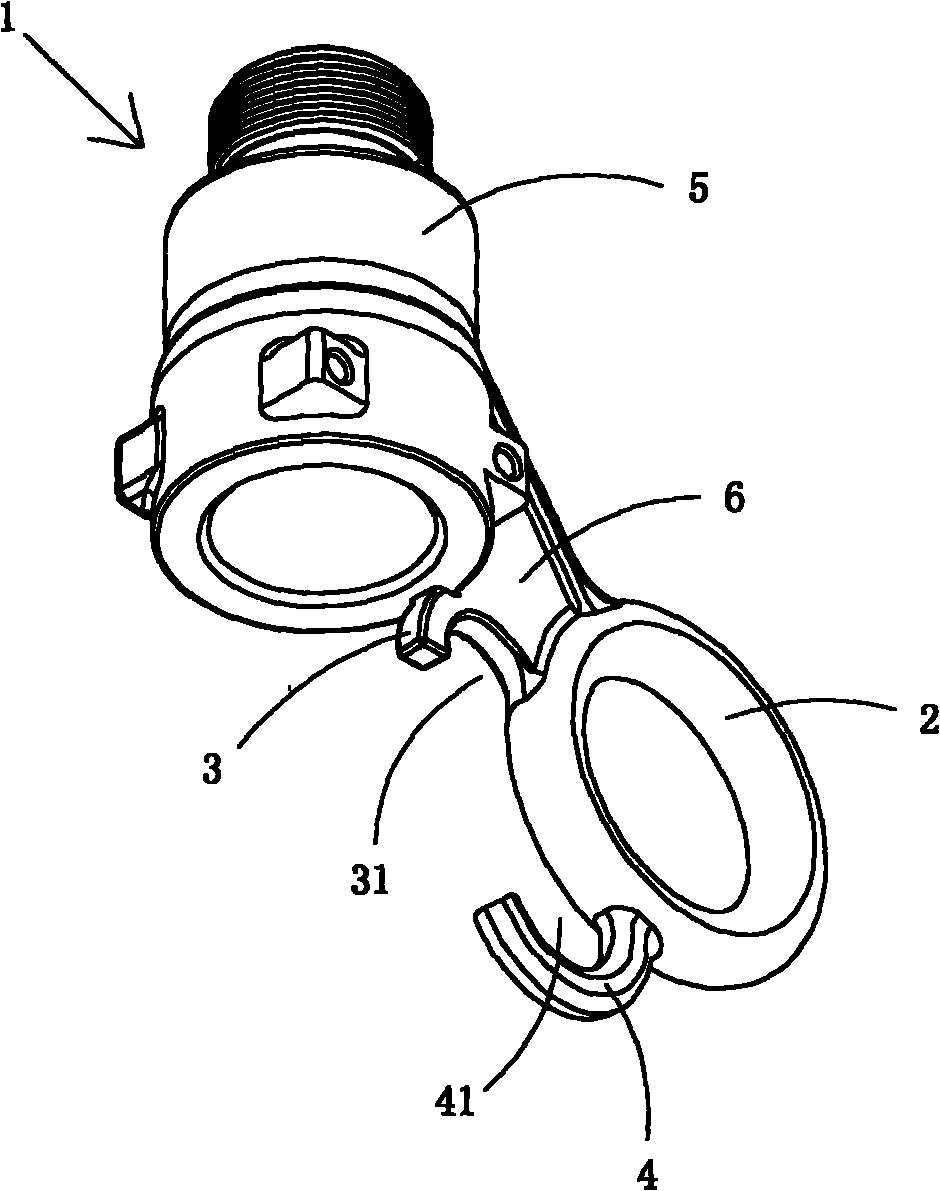

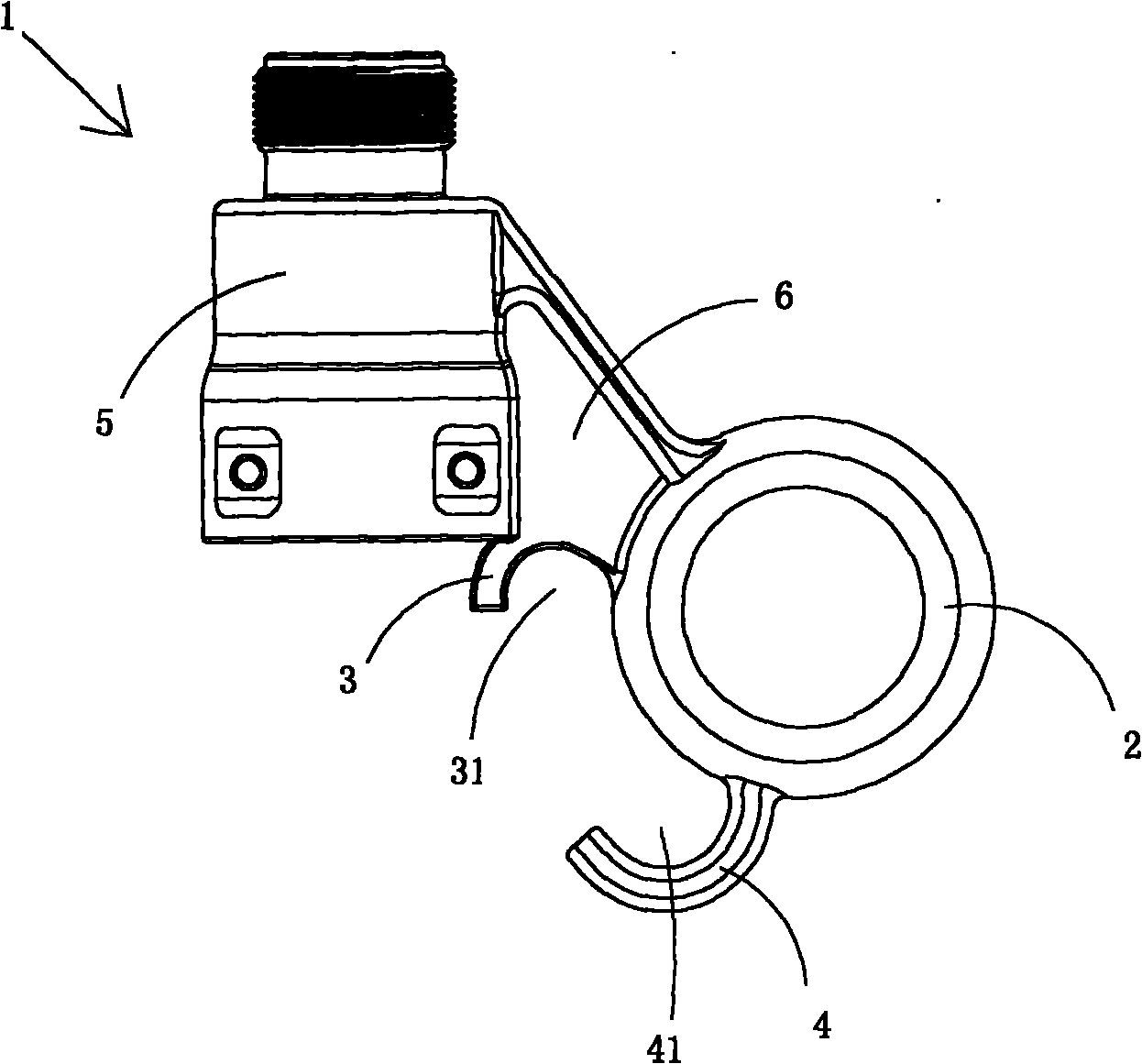

[0026] Figure 1 to Figure 3 A specific embodiment of the manual operating mechanism of the present invention is shown, wherein, figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 A schematic diagram of the three-dimensional structure of the manual operation mechanism shown when viewed from another angle; image 3 yes figure 1 Front view of the manual operator shown.

[0027] This embodiment is a manual operation mechanism for opening and closing of drop-out fuses, see Figure 1 to Figure 3 , including a pull ring sleeve 5, a closed annular pull ring 2, a connecting plate 6, a top hook 3 with a notch downward and a pull hook 4 with a notch upward. The annular pull ring 2 is fixed on the pull ring sleeve 5 through the connecting plate 6 .

[0028] The top hook 3 is arranged at the bottom of the connection end between the connecting plate 6 and the ring sleeve 5 . The pull hook 4 is arranged at the bottom o...

Embodiment 2

[0030] (Embodiment 2, melt carrier)

[0031] Figure 4 It is a three-dimensional structural schematic diagram of the fusion carrier of the present invention, showing a specific embodiment of the fusion carrier of the present invention.

[0032] This embodiment is a fuse-carrying part for a drop-out fuse, including a fuse tube 7, a contact 8 arranged on the top of the fuse tube 7, a fuse-carrying bushing 9 arranged at the lower part of the fuse tube 7, and a fuse tube 9 arranged on the A manual operating mechanism 1 for opening and closing operations on one side of the fusion pipe 7; the manual operating mechanism 1 includes a pull ring sleeve 5, a closed ring pull ring 2, a connecting plate 6, and a top with a notch downward Hook 3 and a draw hook 4 upwards of a breach. The annular pull ring 2 is fixed on the pull ring sleeve 5 through the connecting plate 6 .

[0033] The top hook 3 is arranged at the bottom of the connection end between the connecting plate 6 and the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com