Jigsaw blade

A thorn saw blade and thorn saw technology, which is applied to metal sawing equipment, tools of sawing machine devices, metal processing equipment, etc., can solve problems such as affecting the quality of the cutting surface, and achieve the effect of improving cutting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

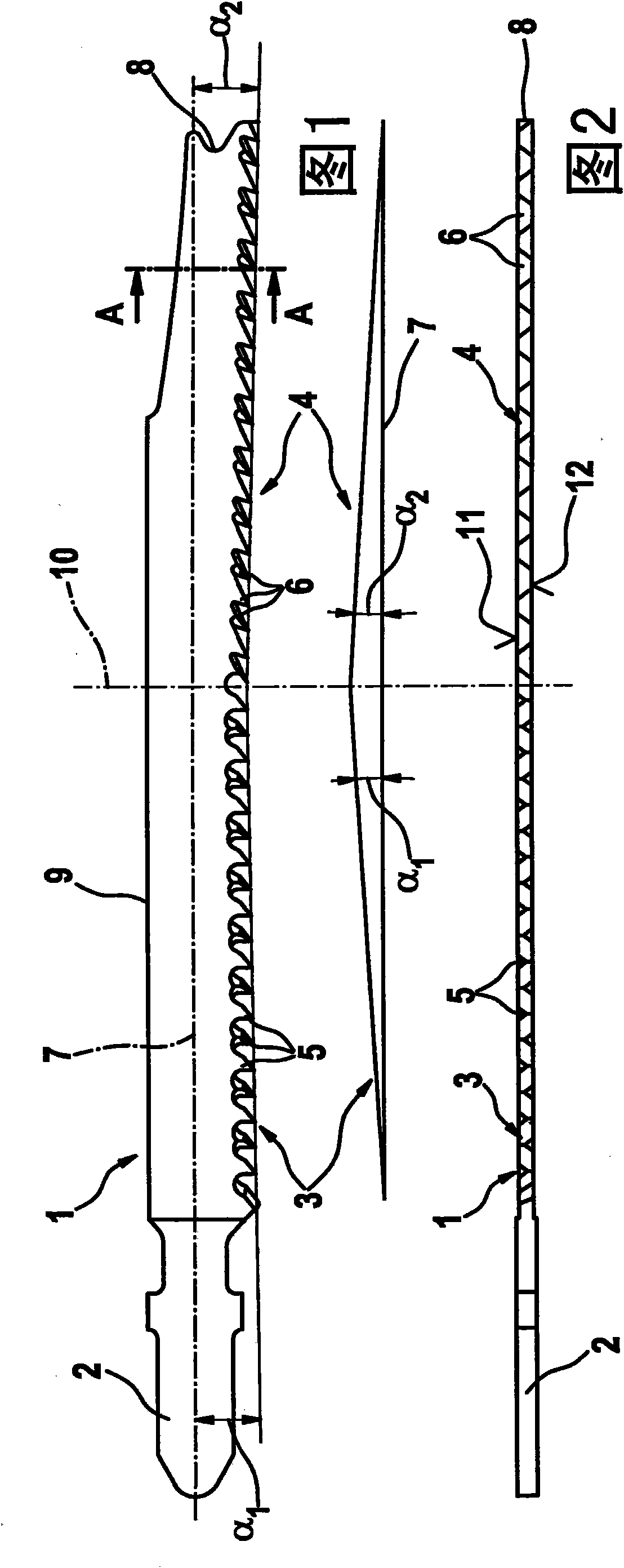

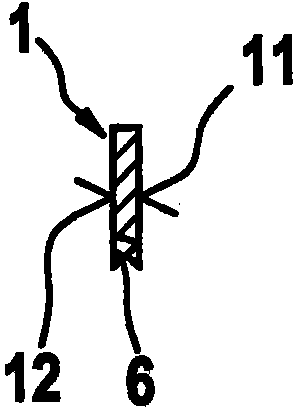

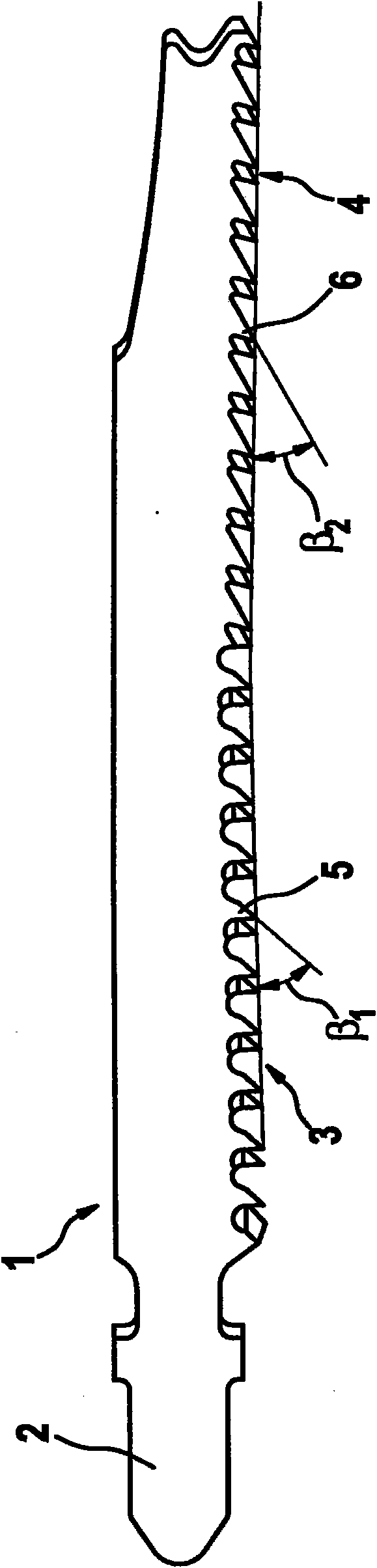

[0020] figure 1 The jigsaw blade 1 described in has a shank 2 by means of which the jigsaw blade is clamped in a motorized saw. On the jigsaw blade, the teeth 5, 6 are distributed on the first sawtooth row 3 adjacent to the handle and the second sawtooth row 4 adjacent to the tip 8 of the saw blade, and the two sawtooth rows 3, 4 are arranged one behind the other and lie in a common plane. The teeth 5 and 6 of the two tooth rows 3 or 4 are each directed towards the shank 2 . The two tooth rows 3 and 4 have approximately the same length, the transition between the tooth rows 3 and 4 being indicated by a straight line 10 . The longitudinal axis of the jigsaw blade 1 is provided with reference numeral 7 , which is at the same time the feed direction or cutting direction of the saw blade 1 , the back side 9 of the saw blade extending parallel to the longitudinal axis 7 .

[0021] The two tooth rows 3 and 4 have an angle α with respect to the longitudinal axis or direction of fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com