Master cylinder, especially for clutch or brake actuation of a motor vehicle

An operating device and active cylinder technology, applied in non-mechanical drive clutches, fluid drive clutches, hydraulic brake transmissions, etc., can solve problems such as troublesome structural design, cracks, etc., and achieve the effect of prolonging life, vibration and load impact attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

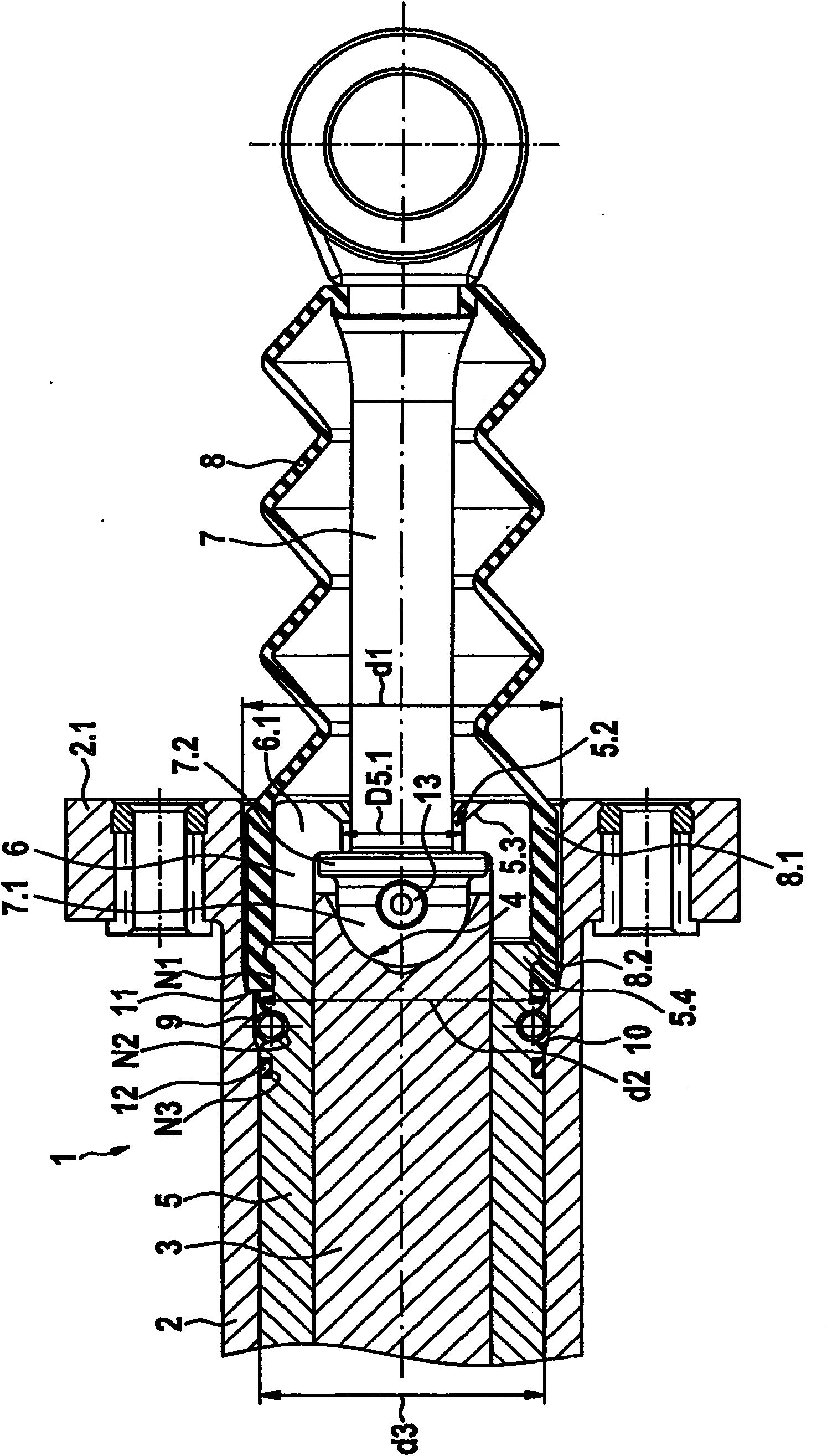

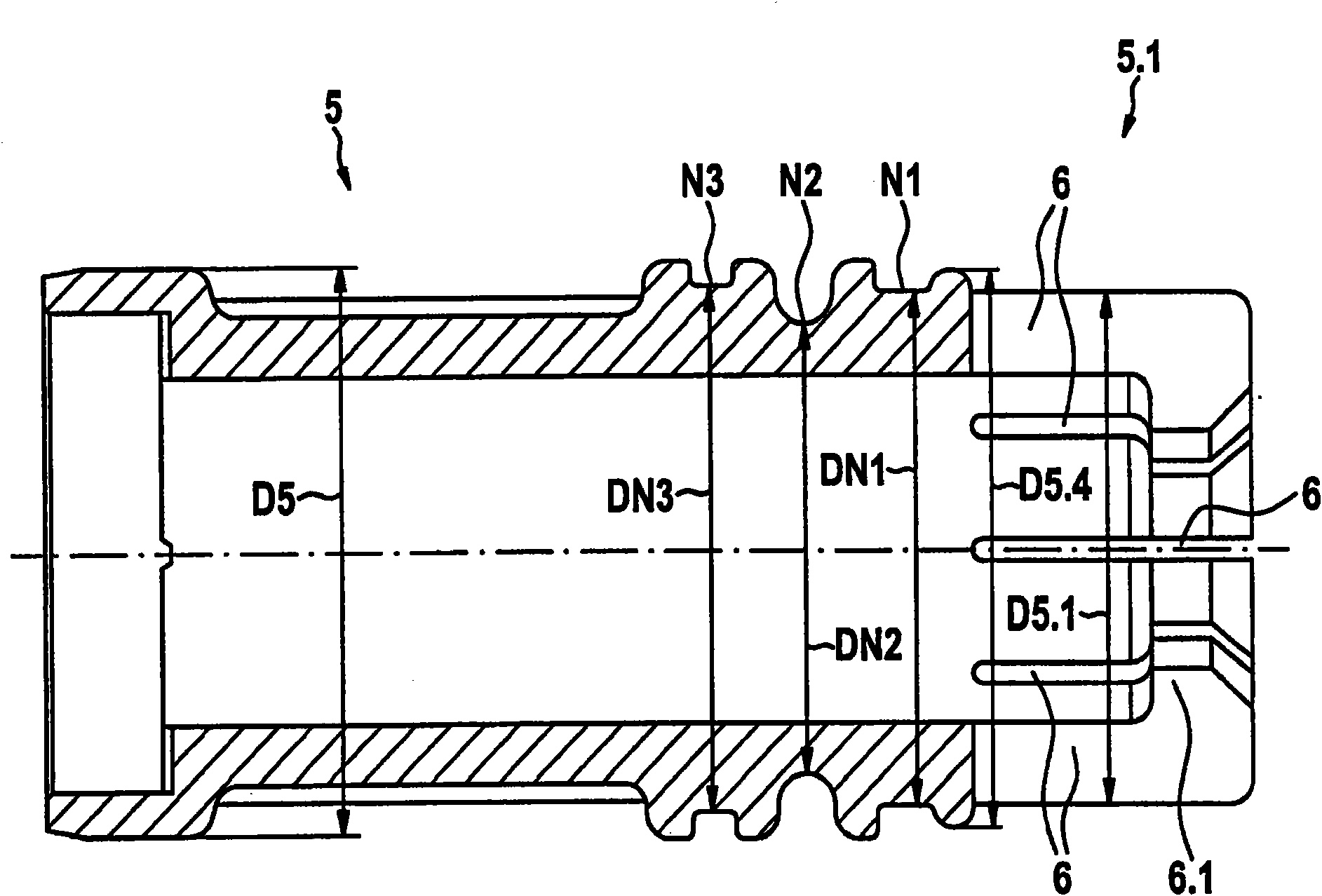

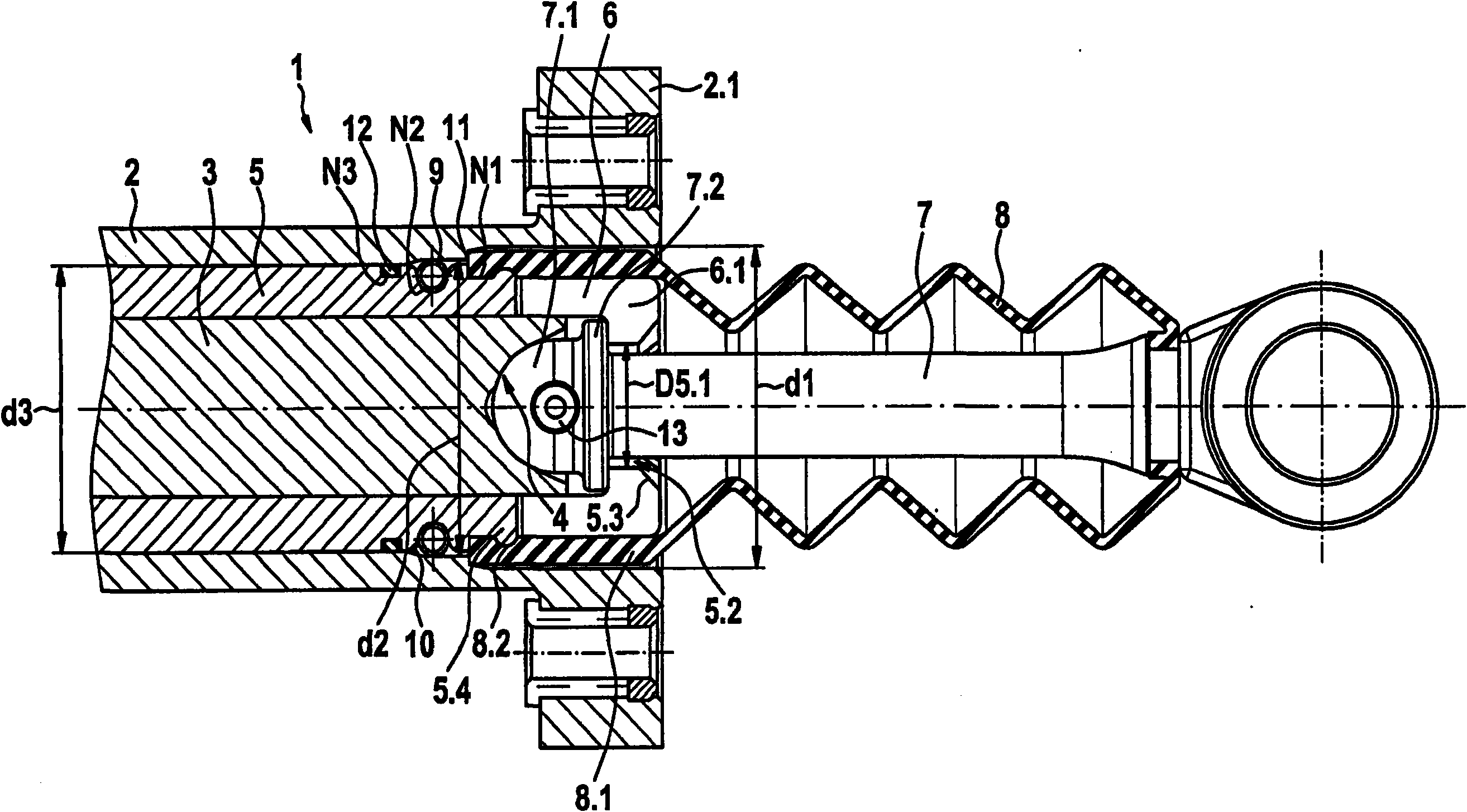

[0023] figure 1 shows a longitudinal section of the piston rod-side end of a master cylinder. figure 2 A detailed partial view of the intermediate sleeve is shown in longitudinal section. Master cylinder 1 has a guide sleeve 2 . In the guide sleeve 2 , a piston 3 with an end recess 4 is mounted axially displaceably in an intermediate sleeve 5 . Intermediate sleeve 5 according to figure 2 There is an end 5.1 provided with an axially extending slot 6. In addition, a radially inwardly directed flange 6.1 and a concentric mounting hole 5.2 are provided on the end 5.1 of the intermediate sleeve 5 . The mounting hole is extended outwards by a subsequent mounting ramp 5.3.

[0024] Adjacent to the end 5.1 of the intermediate sleeve 5 provided with the slot 6 in the outer contour of the intermediate sleeve 5 is a first groove N1, adjoining the first groove at a distance is a second groove N2 and Also adjoining this second groove at a distance is a third groove N3.

[0025] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com