Crane grider overturning and positioning device

A positioning device and crane technology, applied in the directions of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the allowance for difficult-to-control movement of the crane, long workpiece and ground damage, and long workpiece impact. and other problems, to achieve the effect of convenient adjustment, improved work efficiency, and convenient welding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

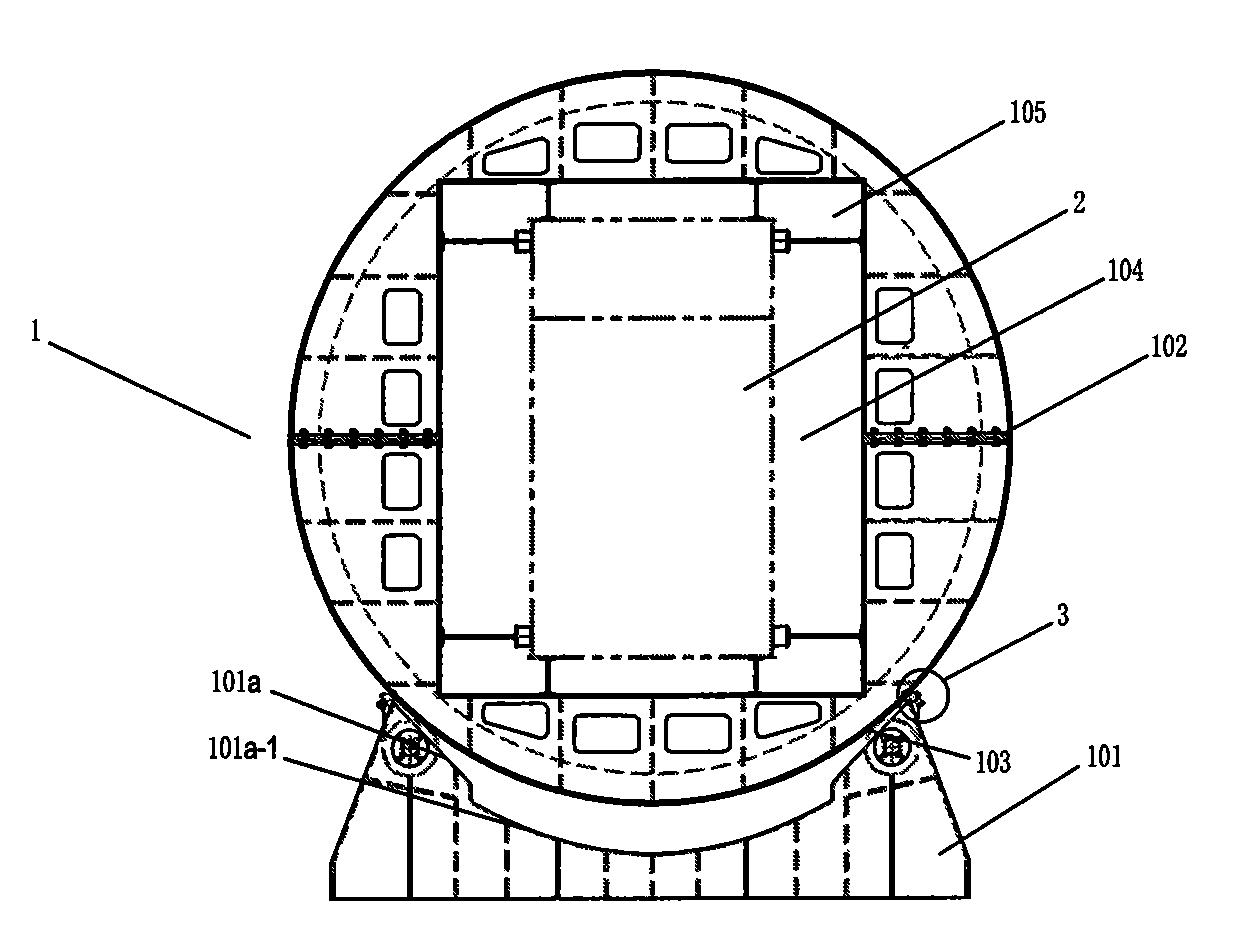

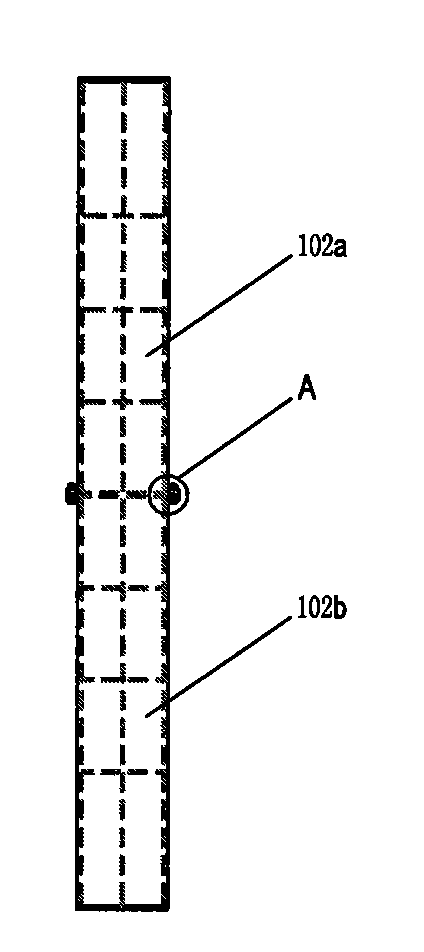

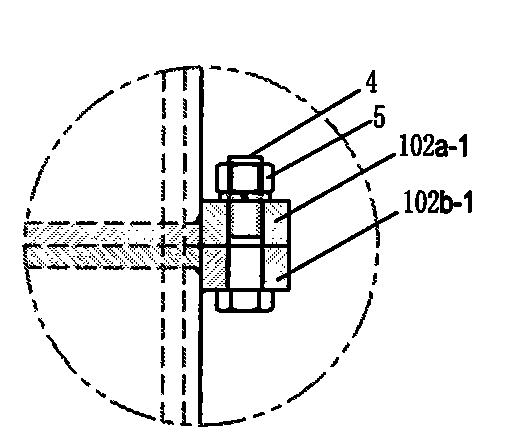

[0019] Such as Figure 1 to Figure 5 As shown, a crane girder overturning positioning device includes at least two overturning frames 1 arranged front and rear. There is a distance between each overturning frame 1 and they are on the same central axis. Each of the overturning frames 1 consists of The base 101, the circular turning body 102 and the roller 103 are composed. The roller 103 is rotatably installed on the left and right ends of the base 101. The circular turning body 102 sits on the base 101 and its arc end surface is offset against the roller 103. The circular overturning body 102 has a central axis hole 104 that is matched with the crane main beam 2. On the central axis hole 104, there are a number of pressing blocks 105 that compress the end face of the crane main beam 2 extending toward the central axis, corresponding to the circular over...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap